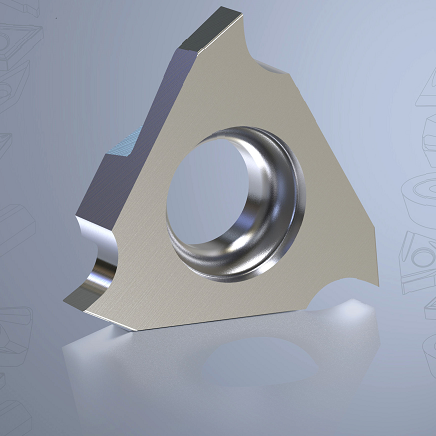

External Grooving Parting inserts No Built Up Edge MC2010 TGF30R200-010 2mm Parting width

Product Details

The cermet insert TGF32R200-010 is suggested for grooving machining of soft steel, stainless steel and gray cast iron. It provides long tool life and it can significantly improve the built-up edge performance.

Cermet grades are used in smearing applications where built-up edge is a problem. Their self-sharpening wear pattern keeps cutting forces low even after long periods in cut. In finishing operations, this enables a long tool life and close tolerances, and results in shiny surfaces.

The cermet may crack after electrical discharge machining (EDM), light grinding is needed before used.

Both dry cutting and sufficient cooling wet cutting are feasible. Avoid insufficient cooling and thermal shock in cutting.

Features

-Excellent wear resistance and crater resistance

- Long tool life

-High red hardness and high cutting speed in dry cutting( environmental friendly)

- Light cutting process

- No built-up edge

Applications

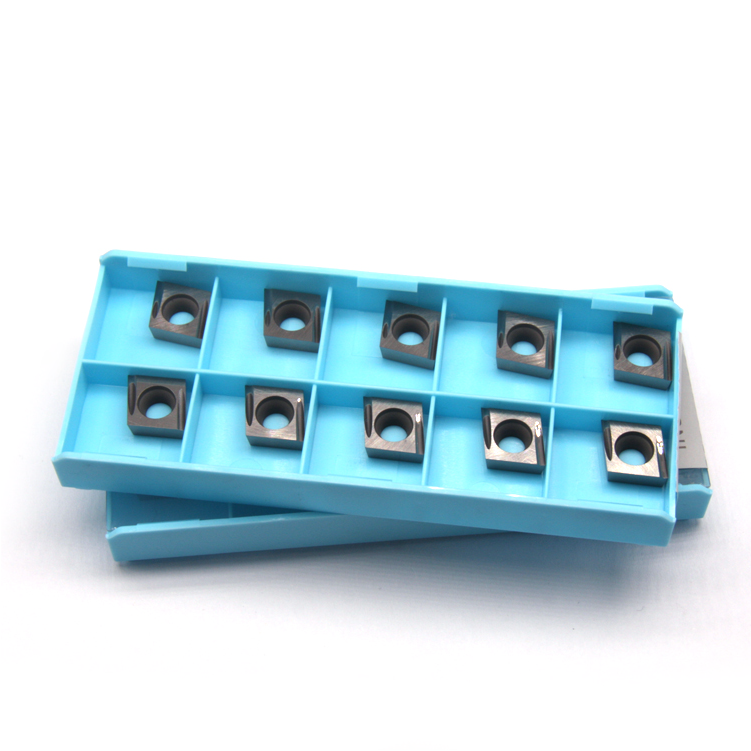

Ti(CN) based cermet is a composite material that combines ceramic and metallic materials. Cermet grades provide long tool life and excellent surface finish, combining toughness with superior wear resistance. Our PVD coated cermet offers less deterioration and more bending strength. This enables you to choose the perfect tool fitting your demand for high performance cutting.

Parameters

| Insert Type | TGF30R200-010 |

| Grade | MC2010 |

| Material | TiCN Cermet |

| Hardness | HRA92.5 |

| Density(g/cm³) | 6.75 |

| Transverse Rupture Strength (MPa) | 2300 |

| Workpiece | Carbon steel, alloy steel, gray cast iron |

| Machining method | Finishing and semifinishing |

| Application | Grooving |

FAQ

Q:What kind of cutting tools do you manufacture?

A:We manufacture a wide range of products including cermet inserts, endmill, blanks, rods, plates and customized products.

Q:What’s the main application of your products?

A: Our products are used for metal cutting applciations such as automobile, medical, die-mold, petroleum, 3C and many other industries.

Q:What kind of payment terms you accept?

A:T/T,West Union,Paypal,Credit Card and other main terms.

Q:Where are you located.

A:We are located in Chengdu, Sichuan Province, where Titanium resource is very rich.

Q:When is the leading time?

A:Normally 10 days after receiving your payment,but it can be negotiated based on order qty and production schedule.

Q:What about the shipment way?

A: We can arrange shipment via DHL, FEDEX, TNT, UPS upon customer’s request.