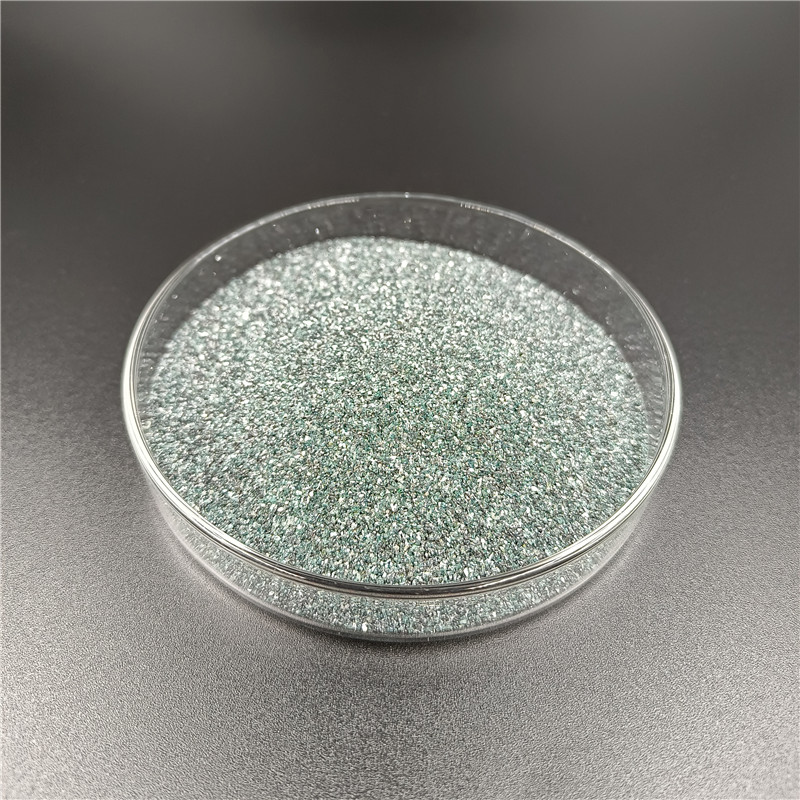

F12-F220 Green silicon carbide grit

Green Silicon Carbide is produced by heating silica sand and a carbon source, typically petroleum coke, to high temperatures in a large furnace.The result of this high temperature process is the crystalline formation of Silicon Carbide grains.High quality,water classified silicon carbide powders graded to exacting standards.

Green silicon carbide powder is a very hard abrasive material with uniform particle size distribution. The hardness of it only ranks after diamond and B4C, and it is harder than black silicon carbide. So it is suitable to grinding large range of hard material such as titanium alloy, marble, carbide alloy, optical glasses, ceramics, etc.

On the other hand, green silicon carbide has extraordinary features such as high chemical stability, low thermal expansion rate, it is suitable for heat resistance & corrosion resistance coatings, paints, and other construction products.

Features

1.high density

2.low thermal expansion, high oxidation resistance

3.excellent chemical resistance

4.high thermal shock resistance

5.high wear and hardness resistance

6.high strength, high temperature resistance

7.high temperature strength