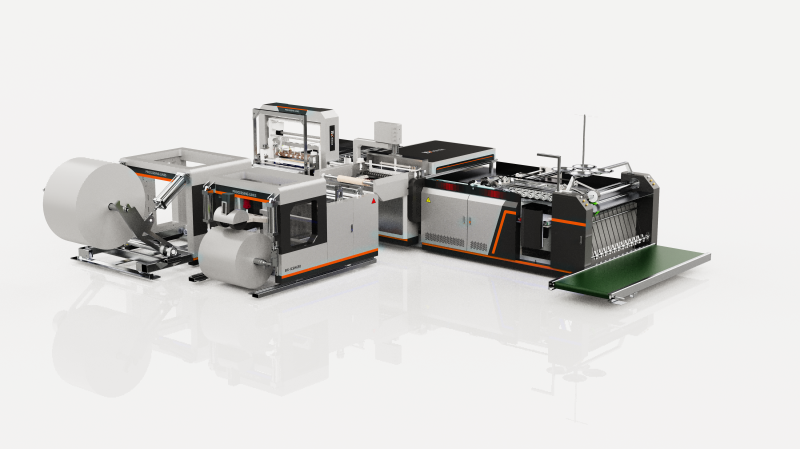

feed pellet making machine for chicken cattle feed pellet

Ring die Feed pellet making machine is a professional equipment for mixing and pressing crushed materials such as corn, soybean, wheat, sorghum, straw, and grass into pellet feed for livestock and poultry. It is a patented product carefully developed by our company combined with domestic and foreign advanced technology, which lasted more than 10 years.

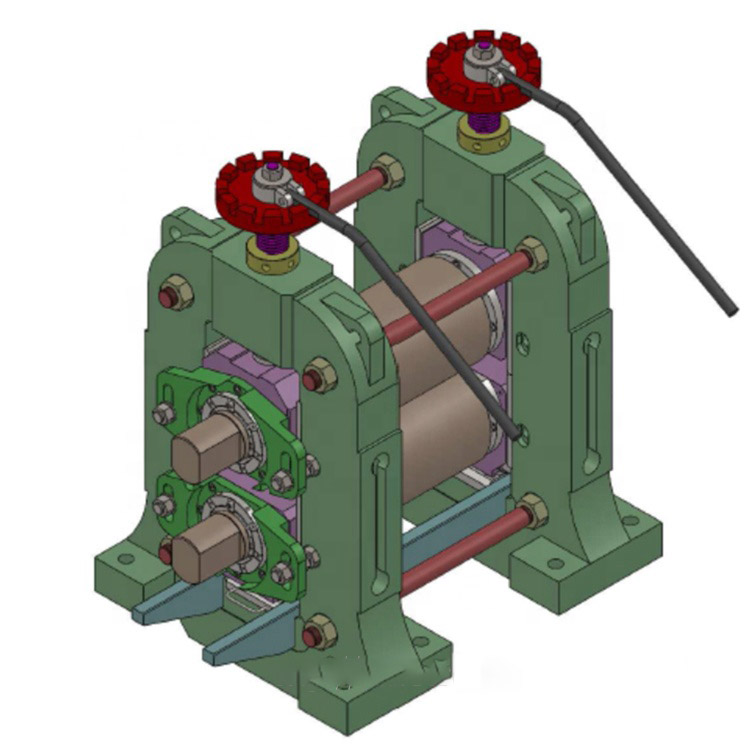

1. The belt is directly connected to the transmission, with large driving torque, stable transmission and low noise.

2. The ring die adopts a quick-release hoop design, easy to replace, high efficiency and large output.

3. The opening area of the ring die is increased by 25% to achieve the best area-to-power ratio.

4. Novel and compact structure, low noise, easy operation and maintenance, stable and safe.

5. Different forms of modulators and feeders can be selected according to needs;

|

Model |

SZLH250 |

SZLH320 |

SZLH350 |

SZLH420 |

SZLH508 |

SZLH678 |

SZLH768 |

|

Main Motor |

15/22 KW |

37/45 KW |

55 KW |

110 KW |

160 KW |

200/220/250 KW |

250/280/315 KW |

|

Bearing |

NSK /SKF |

||||||

|

Capacity |

1-2T/H |

2-3T/H |

3-6T/H |

8-10T/H |

10-15T/H |

12-25T/H |

15-30T/H |

|

Screw Feeder |

1.1KW, 2.2KW, 3KW, 5.5KW, 7.5KW..etc. Frequency control. |

||||||

|

Inner diameter of ring die |

Φ250mm |

Φ320mm |

Φ350mm |

Φ420mm |

Φ508mm |

Φ678mm |

Φ768mm |

|

Qty. of roller |

2pcs |

||||||

|

Rate of pellet formation |

≥95% |

||||||

|

Rate of pellet powdering |

≤10% |

||||||

|

Noise |

≤75 dB(A) |

||||||

The Ring die Feed pellet making machine have been export to America, Spain, Mexico, Georgia, Malaysia, Indonesia and so on, we have 20 years experience, we can provide the suitable proposal to customers.

1.Are you a factory or a trading company?

We have our own factory. we have over 20 years of experience in the pellet machine manufacturing. “Market our own products” reduces the cost of intermediate links. OEM available according to your raw materials and output.

2.Our workers don’t know how to operate the pellet mill, what should I do?

Our engineers will guide the field workers how to install the machine and arrange the workshop layout. Our engineers will then test run the live production line and train your workers how to operate it.

3. What payment term do you accept?

We support various payment methods, we can accept 20%-30% as a deposit. Customer pay the balance after the end of production and inspection. We have more than 1000 square meters of spot stock workshop. It takes 5-10 days for ready-made equipment to be shipped, and 20-30 days for customized equipment. We will do our best to deliver as soon as possible.

4.Where is the market for the product and where is the market advantage?

Our market covers the entire Middle East and European and American countries, and exports to more than 34 countries. In 2019, domestic sales exceeded RMB 23 million. The export value reached 12 million U.S. dollars. And the perfect TUV-CE certificate and reliable pre-sales and after-sales service are what we have been working hard to do.