Fiber laser cutting machine CE3015

|

Technical parameters |

||

|

1 |

Model |

CE3015 |

|

2 |

Effective Cutting Width(mm) |

1510 |

|

3 |

Effective Cutting Length(mm) |

3010 |

|

4 |

Lift(mm) |

0-80 |

|

5 |

Input power |

AC380V/50Hz;AC220V/50Hz |

|

6 |

Cutting thickness(mm) |

Stainless steel 4mm, carbon steel 8mm,Aluminum 2mm |

|

7 |

Cutting speed( mm/min ) |

21000 (1000W/δ1mm ) |

|

8 |

Idle speed( mm/min ) |

100000 |

|

9 |

Max acceleration (G) |

1.2 |

|

10 |

Position repeat accuracy |

±0.05 |

|

11 |

Drive mode |

Precision rack bilateral drive |

|

12 |

Laser wavelength(nm) |

1080 |

|

13 |

cooling mode |

water-cooling |

|

14 |

Environment temperature |

5-35℃ |

|

15 |

Cutting material |

Carbon steel, stainless steel, alloy steel, copper, aluminum, galvanized sheet |

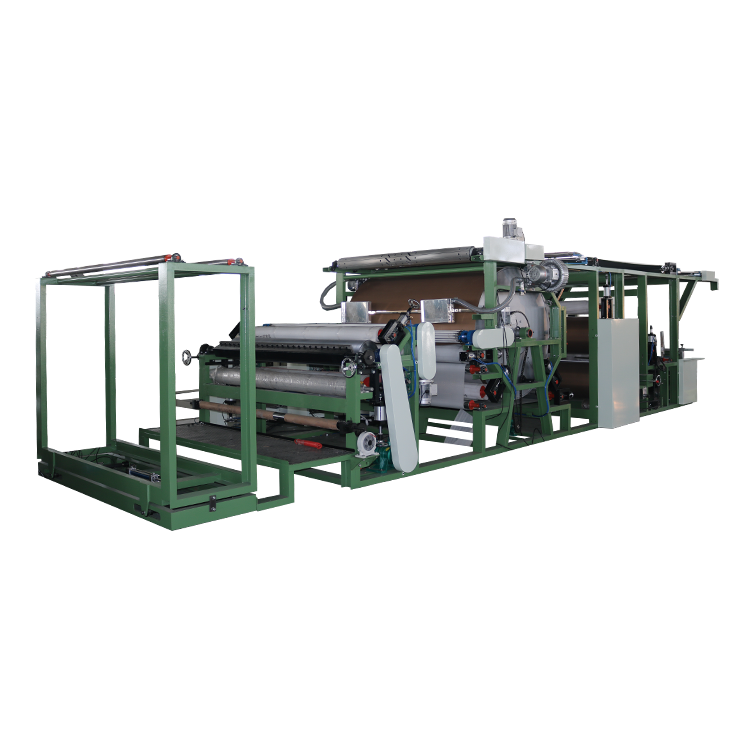

The product adopts the double-drive structure of the door, the bed is the integral weldment, and the bracket is welded as a whole. Both of them are roughed after annealing, and after the secondary vibration aging treatment, the whole finishing is completed to obtain a very high shape. Position tolerance accuracy; transmission equipped with French Modoreducer precision reducer, Taiwan YYC grinding rack, Taiwan Hiwin high-precision linear guide and other high-efficiency transmission mechanism, good rigidity, high precision, guarantee long-term high-precision operation; through advanced cypress The Weihong CNC system is a combination of laser cutting, precision machinery, numerical control technology and other disciplines of precision CNC fiber laser cutting machine.

Technology: After years of research and development and innovation, the fusion of cutting-edge laser technology, the introduction of Italian Prima-Power cutting process, fiber transmission, suitable for cutting all kinds of complex parts; powerful CNC system and nesting software solve many technical problems, further improve Cutting precision, piercing speed, simple and convenient operation.

Efficiency: The compound motion speed is up to 60m/min for high-efficiency machining.

Safety: The use of sheet metal shield design, mechanical and electrical linkage, effectively block the combination of lasers, greatly improve the safety performance; fiber laser uses semiconductor modular and automated design for 24-hour continuous operation.

Energy saving: easy to use and flexible, more than 32% electro-optical conversion efficiency; good beam quality, small spot size, close to Gaussian distribution spot energy; modular plug-and-play design, compact and firm structure; fiber optic loop measurement, fiber optic head detection, temperature Switches, water leak sensors and comprehensive safety measures enable multiple protections for lasers and personnel.

☆ Samples:

We Take part in trade fair