Flannelette Raising Needle — Fork Needle

Product Description

Quick Details

Product name: Felting needles

Warranty: 1.5 years Applicable

Brand Name: YUXING

Use: NEEDLE LOOM

Type: NEEDLE BOARD

Production capacity: 600 million

Condition: New

Raw material: HIGH CARBON STEEL

Place of Origin: Zhejiang, China Brand

Application: For Needle nonwoven fabric

Packing: Well packed from water and damage

Packaging & Delivery

MOQ: 10000pcs

Selling Units: Multiple of 10000

Package size per batch: 32X22X10 cm

Gross weight per batch: 12.00 kg

Package Type: 500pcs into 1 plasitc box, then 10000pcs again into 1 carton box

Picture Example:

Lead Time:

|

Quantity(Pieces) |

1 - 500000 |

>500000 |

|

Est. Time(days) |

10 |

To be negotiated |

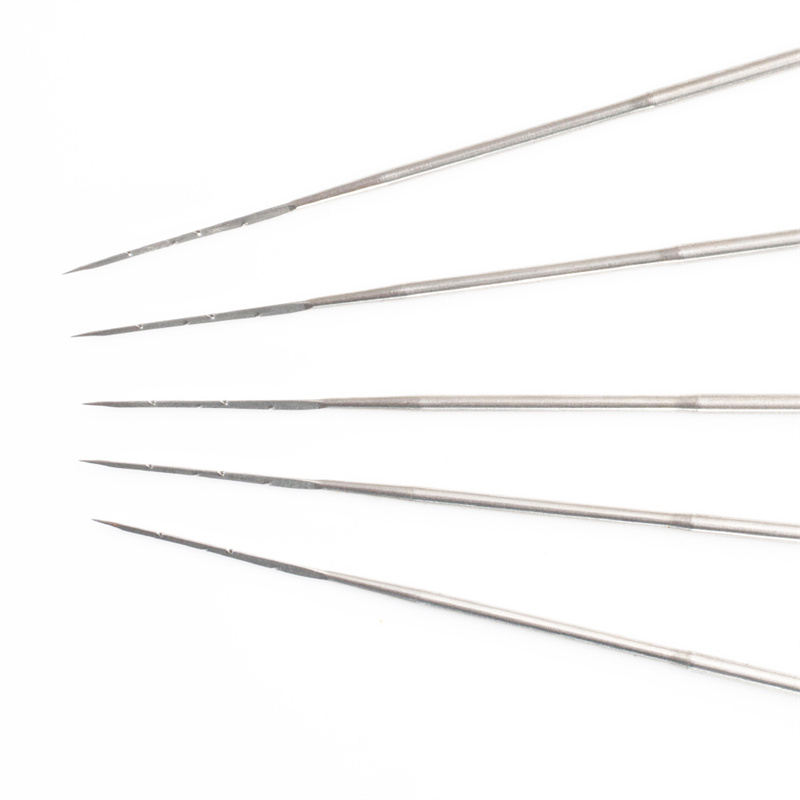

Products Show

Product Description

Gauges and diameters of Felting Needles

|

Gauge |

working part |

2nd Intermediate Section |

1st Intermediate Section |

Shank |

|

15 |

1.83 |

|||

|

16 |

1.55 |

|||

|

17 |

1.35 |

1.35 |

||

|

18 |

1.20 |

1.20 |

||

|

19 |

1.10 |

1.10 |

||

|

20 |

0.95 |

0.95 |

0.95 |

|

|

22 |

||||

|

23 |

||||

|

25 |

0.80 |

0.80 |

0.80 |

|

|

26 |

||||

|

28 |

||||

|

30 |

0.70 |

0.70 |

||

|

32 |

0.65 |

0.65 |

||

|

34 |

||||

|

36 |

0.55 |

0.55 |

||

|

38 |

0.50 |

0.50 |

||

|

40 |

0.45 |

|||

|

42 |

0.40 |

|||

|

All diameters of the parts designation on a fork needle are expressed in gauges(gg). The smaller the gauge number, the bigger the respective diameter. The various diameters are listed in the chart. All parts of the fork needle, as well as the working part, have a round cross section. |

||||

|

Detailed parameters of the felting needle |

||

|

Product name |

Quadro Needles |

|

|

texture |

high-carbon steel |

|

|

colour |

bright nickel white |

|

|

Nominal length |

76.0mm |

|

|

66.5mm |

||

|

65.0mm |

||

|

63.5mm |

||

|

62.0mm |

||

|

In the fork needle description, the nomianl length is given in milli-meters(mm). The most common nominal length is 63.5mm or2.” From this dimension there are increasment of 1.5mm lor longer or shorter needles, which are used for deep patterning designs. In addition to these needles, there are also needles available with anominal length of 76mm or3″. The drawings of the needles specify the nominal length or the fork needle. |

||

|

Standard working part lengths on fork needles |

5.5mm |

|

|

8.5mm |

||

|

13mm |

||

|

14.5mm |

||

|

15.5mm |

||

|

17mm |

||

|

The working part length is determined by the required stability and penetration depth of the needles used. Various types from single reduced to multi reduced needles are available. On fine gauge multi reduced needles, a short working part length is required. The short working part and the intermediate blade gives the needle the necessary stability and minimizes the widening of the fabric. |

||

Application field

Nonwovens are a class of materials in which fibers are bonded together by high temperature, chemical or mechanical means. Among them, mechanical bonding requires the use of needles as tools. In the process of mechanical bonding, the fibers are passed through and entangled into the fabric through the needles with burrs, which improves the friction between the fibers and increases the bonding effect of the non-woven fabric. Needle making machine is a kind of special equipment, and a large number of needles are housed in its dial. The needles pass through the nonwoven in a prescribed direction, intertwining the fibers together. Needle making machines are mainly used in the production of geotextiles, filter cloths, filter bags, artificial leather, disposable carpets, automotive interiors, handmade wool, pure cotton, bra cotton and other products that have surface requirements. To sum up, mechanical needle making is a technology that bonds fibers together, which can enhance the bonding effect of non-woven fabrics. Needle making machines are special equipment used to realize this process, and are widely used in the production of many products that require surface requirements.

Automotive Interior

Soundproof Cotton

Artificial Leather

Filter Bag

Linoleum Machine

Cloth Geotextile

Filter Cloth

Car Cloth

Disposable Carpet

Features

•The needle handle has one or more tapering cones, and the working part is cylindrical

•Three-dimensional rounded forks

•V-shaped or D-shaped crosses

Advantages

•Gently hook fiber for longer service life

•Needle body is extremely straight and does not break or bend the needle

•The appearance of the fabric is affected by the V-shaped and D-shaped crosses

•High uniformity in structured machining

•Distinctive coils (grain texture)

•Efficient fiber processing capability for extremely dense surface quality

•High processing reliability, excellent product quality

•The cross section of the working area is extremely fine, with the best surface quality (smaller funnel groove)

Our Company

Contact Us

If you have another question, pls feel free to contact us as below:

tkp1223@163.com

qshngqx@163.com

Phone

+86 18858673523

+86 15988982293