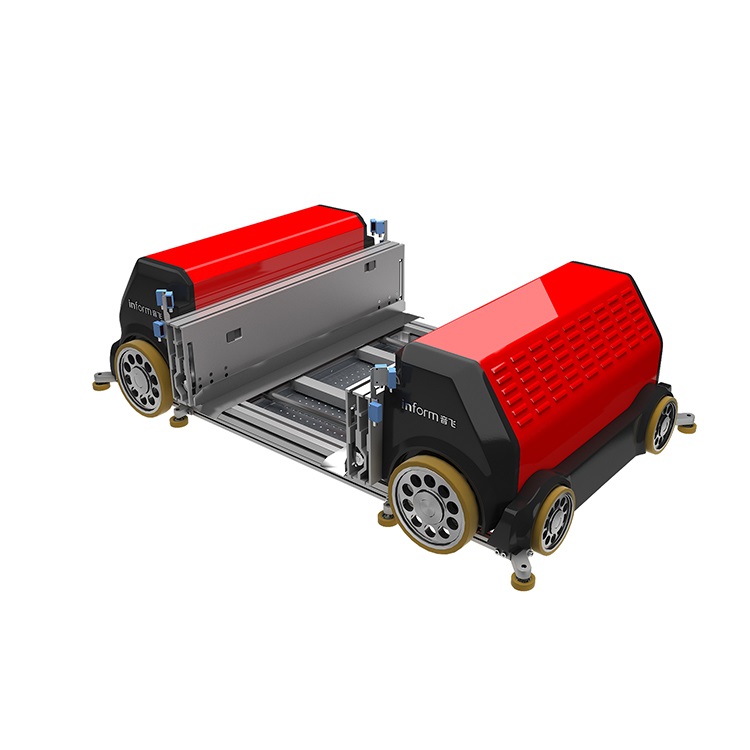

Four-Way Multi Shuttle

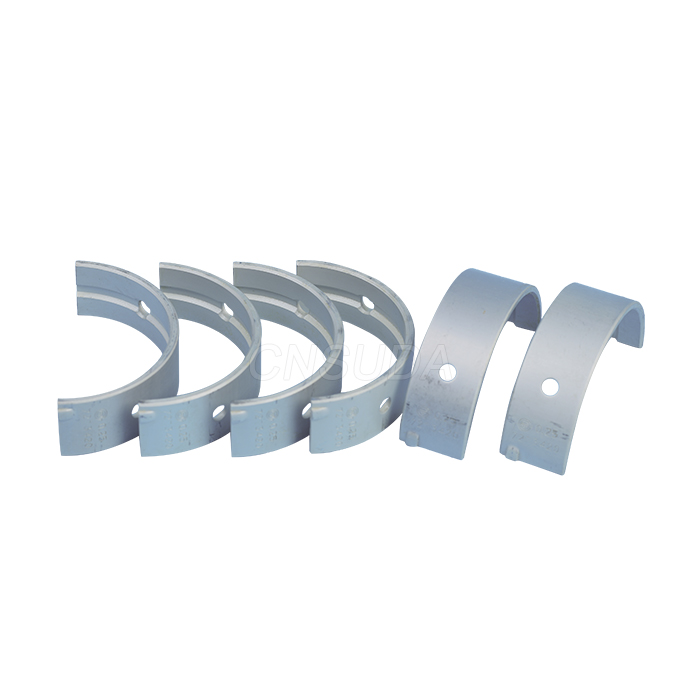

Racking Components

Product Analysis

| 1 | Automatic single inbound | Accepting instruction from host computer, automatically conveys box on inbound buffer area to specified position. |

| 2 | Automatic single outbound | Accepting instruction from host computer, conveys box on specified position to outbound end. |

| 3 | Automatic shifting | Accepting instruction from host computer, conveys box from one specified position to another. |

| 4 | Charging online | Multi-level power threshold control, self-judging and self-charging on line. |

| 5 | Self-learning function | Automatically measure, identify data of racking and pallet, and enter parameters independently. |

| 6 | Task management | Accept task instructions to resolve task path. |

| 7 | Remote function | It is capable of updating and downloading program remotely (In Wi-Fi Network). |

| 8 | System monitoring | Monitors system data in real time and alarm raised in sound and light in abnormal status. |

| 9 | Heartbeat check | Communicate to host computer control system in real time by heartbeat check, monitoring online status |

| 10 | Emergency Stop | Emergency signal sent remotely when emergency, and shuttle stops instantly until emergency lifted.It is capable of guaranteeing device or goods stop safely in maximal deceleration when it executes this instruction. |

②What kind of goods are suitable for Four-way Multi Shuttle Storage System ?

Goods package type: Bins, cartons, totes and etc.

Goods dimension(mm): Width 200-600mm,Depth 200-800mm,Height 100-400mm

Good weight: <=35kg

Operation height: <=15m

③Features

Four-way running.

Processing capacity 3-4 times than AS/RS.

Very suitable for small bins, cartons, tote storage, picking, replenishment work.

It is possible to flexibly add more shuttles at any stage and improve system throughput according to business needs.

An efficient solution for temporary storage and support operation on the side of production line.

④Design, Test &Warranty

Design

Free design could be provided with the following information.

Warehouse storage area Length____mm x Width____mm x Clear height___mm.

Warehouse’s door position for loading and unloading goods.

Bins/cartons Length____mm x Width____mm x Height___mm x Weight_____kg.

Warehouse Temperature_____Degrees Celsius

Inbound and outbound efficiency: Quantity of bins/cartons per hour_____.

Test

Four-way Multi Shuttle will be tested before delivery. Engineer will test the whole system on-site or online.

Warranty

Warranty is one year. Fast response within 24 hours for overseas customer. Firstly test online and adjust ,if couldn’t repair online , engineer will go and solve the problems on site. Free spare parts will be supplied during the warranty time.

Project cases