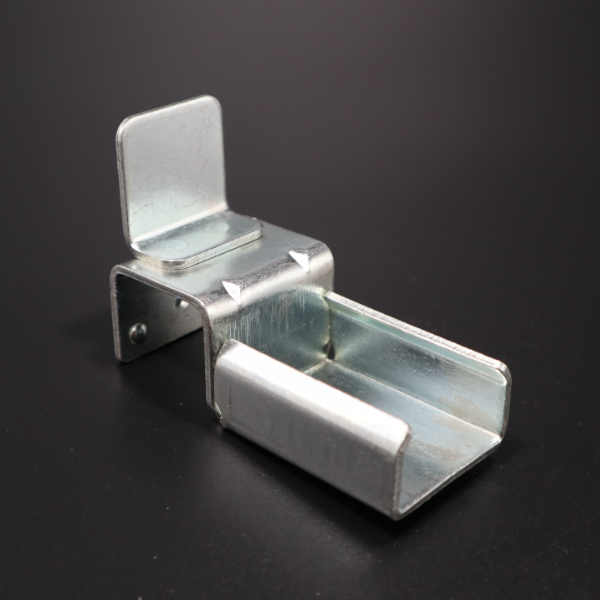

Fuel Plunger F019D03313 For Cp2.2 Pump

products description

| Reference. Codes | F019D03313 |

| OE/OEM Codes | / |

| Application | Pump |

| MOQ | 4PCS |

| Certification | ISO9001 |

| Place of Origin | China |

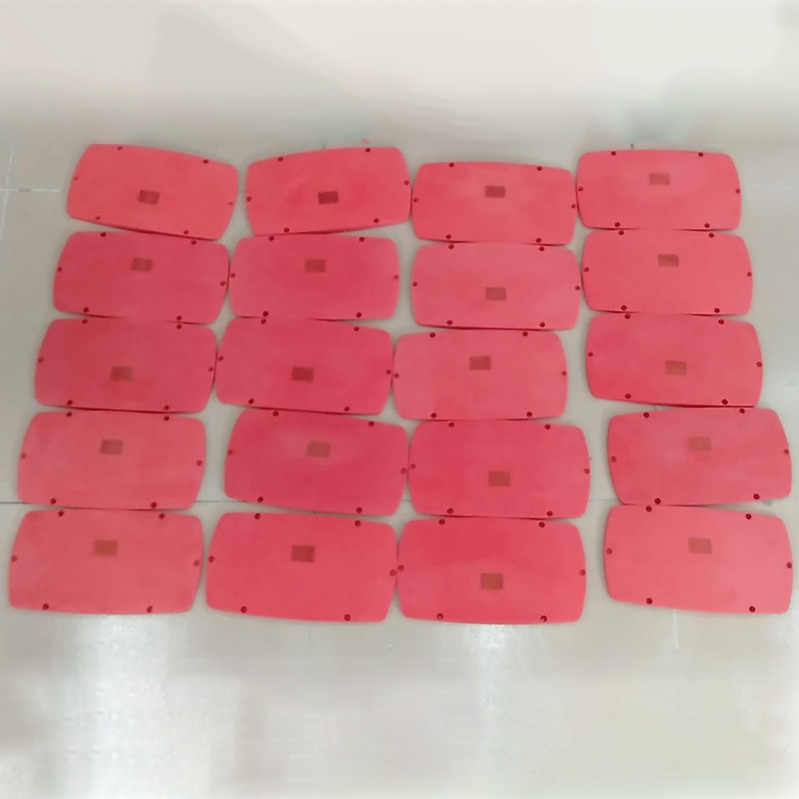

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, L/C, Paypal, Western Union or as your requirement |

Contact us

Not sure what type you need? Give us a call to discuss your project:

Whatsapp: +86 17359166820

Diesel engine fuel injector structure and working principle

Everyone should know that the function of the fuel injector is to atomize the fuel into finer particles, reasonably distribute it into the combustion chamber, and mix it with air to form a combustible mixture.

The working conditions that the injector should meet are that the injection should have a certain injection pressure and range, as well as a suitable injection cone angle and injection quality;

The oil supply should be cut off quickly at the specified time when the oil injection is stopped, and there will be no oil dripping at the end of the oil injection. The fuel supply of each cycle should meet the requirements of less fuel injection in the initial stage, more fuel injection in the middle stage, and less fuel injection in the later stage.

Let’s take a look at the type, structure and working principle of diesel injectors. Injector Type:

Generally can be divided into open and closed. At present, closed injectors are widely used in diesel engines. The injectors currently used are closed injectors, hole injectors and pin injectors. The fuel injector of the closed injector is a pair of precision couplings composed of a needle valve and a needle valve body, and the fit clearance is only 0.002 ~ 0.004 mm.

Therefore, they still need to be paired and polished after finishing, so they cannot be interchanged during use.