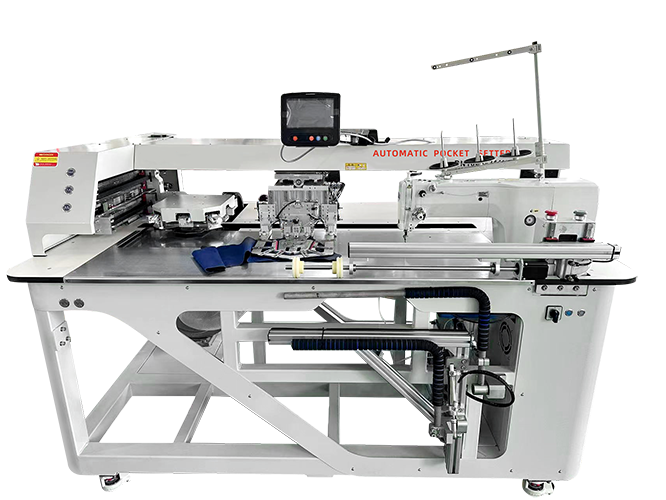

Fully Automatic Pocket Setting Machine TS-299

1, High efficiency: 6-8 pockets/ minute. Using this pocket setting machine it can save 5 to 7 workers for factory.

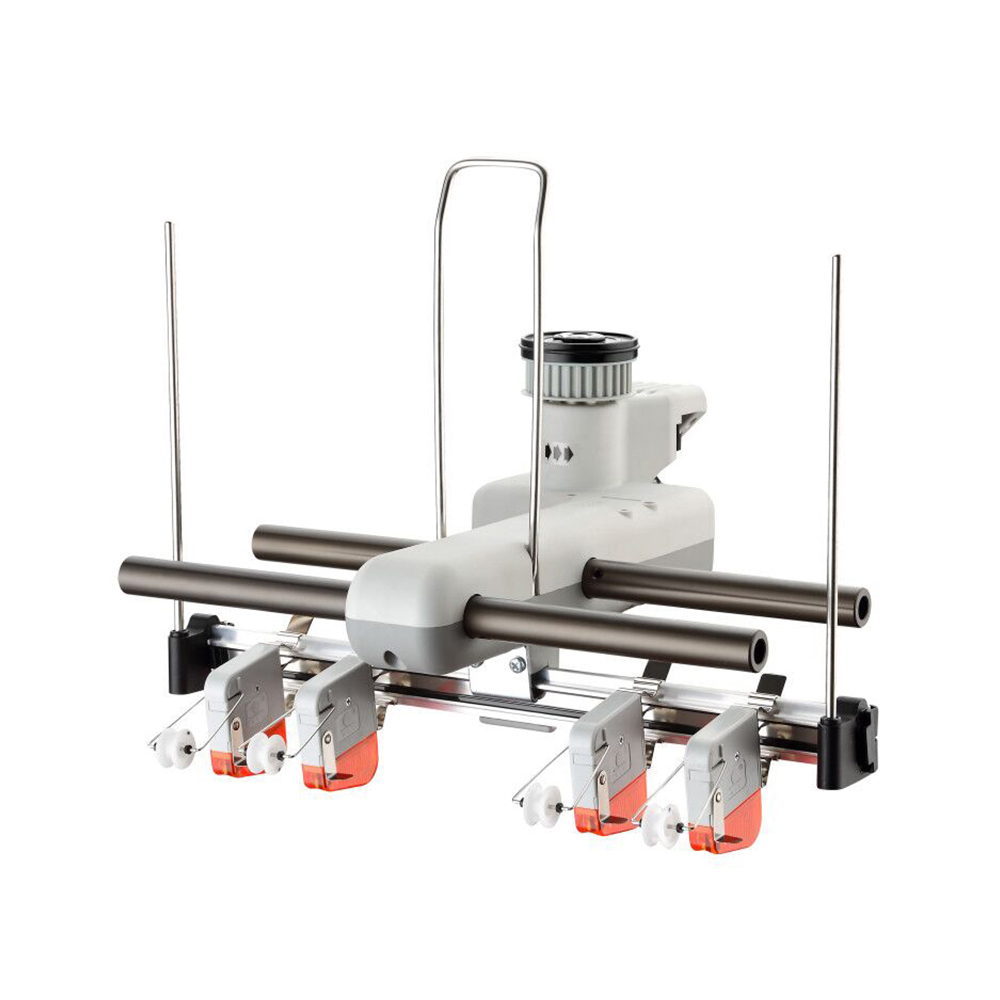

2, Quick change mold: it only need two minutes to change the mold, and it’s very easy for workers. It greatly improved work efficiency. Most important the cost of mold is cheap. This pocket setting machine saves the factory a lot of costs on molds.

3, Full servo drive, fast speed, lower noise,stable performance and good product effect. After years of market testing, now pocket setting machines are more and more stable.

4, Pocket could be different shapes: such as round, square, triangle etc.

5, This pocket attaching machine can work on different thickness fabric: such as jeans, shirt, casual, sports, shirt and t-shirt.

And it can work on different fabric, like as knitted fabric and woven fabric.

6, Some pants require washing water stickers, and the pocket setting machine can also add this device according to customer needs.

ThIS Pocket Setter is suitable for any kind of exterior pockets, focusing on jeans, shirts, casual pants, military trousers and work clothes and other similar sewing products.

| Highest sewing speed | 4000rpm |

| Machine head | Pattern machine 3020, optional Brother 7300A and JUKI 9000B |

| Machine needle | DP*5-DB*5 |

| Sewing stitch programming | Input mode of operation screen |

| Line programming storage capacity | Up to 999 kinds of patterns can be stored |

| Stitch distance | 1.0mm-3.5mm |

| Pressure foot rising height | 23mm |

| Sewing pocket range | X direction 50mm-200mm Y direction 50mm-200mm |

| Speed of sewing pockets | 6-8 pockets per minute |

| Folding method | Double cylinder folder in 7 directions works simultaneously to fold pockets |

| Pneumatic element | AirTAC |

| Feeding drive mode | DELTA servo motor drive (750w) |

| Power supply | AC220V |

| Air pressure and air pressure consumption | 0.5Mpa 80dm3/min |

| Weight | 700Kg |