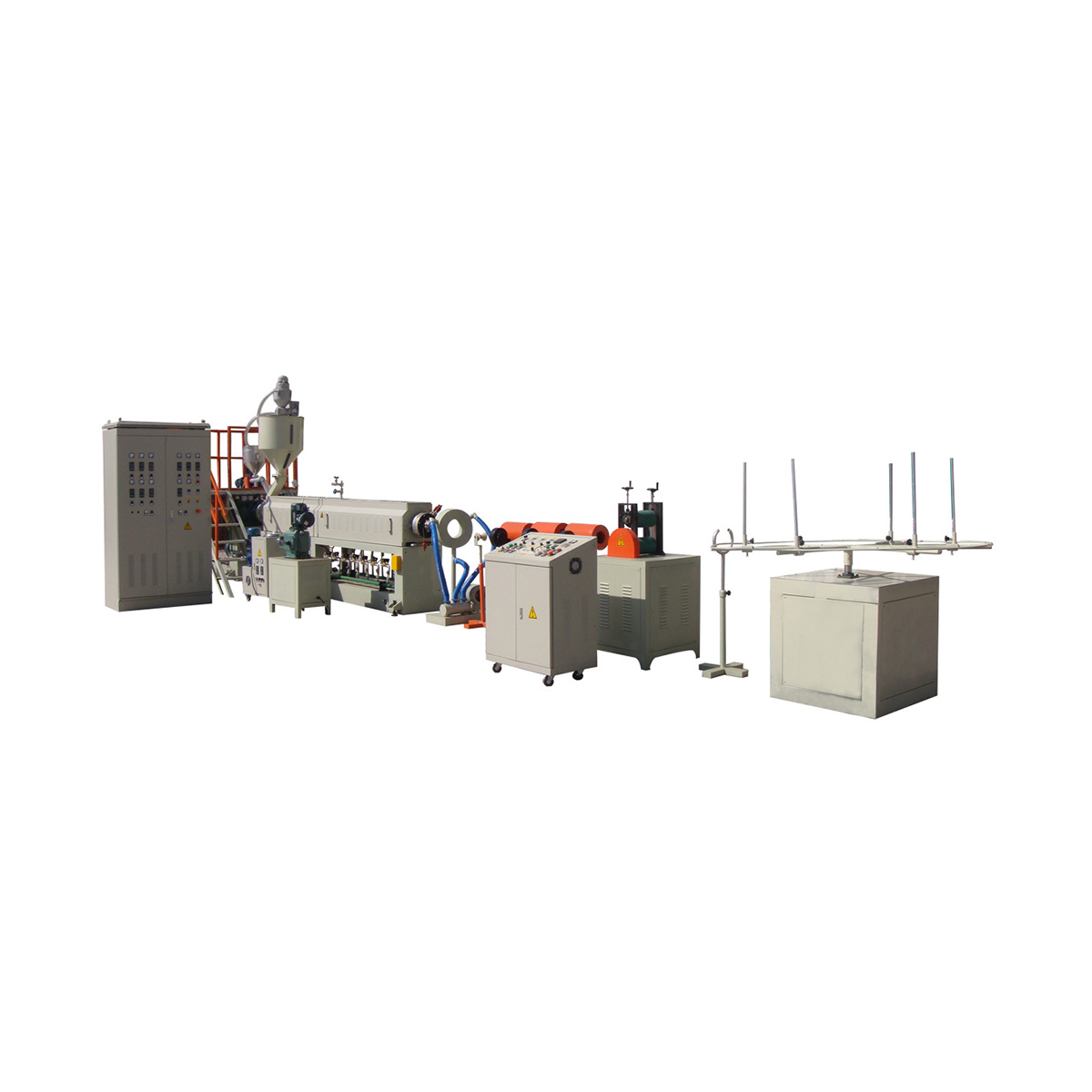

Grassland Fence Machine For Making Deer Fence / horse fence

Machine Feature

1. Special hole for line wire feeding, more flexible and tidy.

2. Instead of groove rail, we adopt linear rail to push cross wire, less resistance, moving fast.

3. Straightening rollers for weft wires, finished weft wire more straightened.

4. Pneumatic turning weft wire, more swift and flexible, to ensure high working speed.

5. Weft wire distance can be adjustable 50-500mm with the special device.

6. Cutter and Twisted head are made of hardened mold steel, life is at least one year.

7. Grid counter to record weaving roll length.

8. Mesh roller is easy to discharge and install.

9. Instead of electric-magnetic motor, we adopt frequency-variable motor controlled by inverter, adjustable working speed, saving 30%energy.

10. We adopt China top brand reducer, no oil leaking, life is at least 5 years.

11. Special sensor to detect cross wire feeding, if wire used up, the machine stops automatically.

specification

| Ineer wire diamerer |

1.8-2.5mm | 1.8-2.5mm | 1.8-2.5mm | 1.8-2.5mm | 1.8-2.5mm |

| Edge wire diameter |

2.0-3.5mm | 2.0-3.5mm | 2.0-3.5mm | 2.0-3.5mm | 2.0-3.5mm |

| Fence height | 1490mm | 1652mm | 1880mm | 2000mm | 2400mm |

| Produce efficiency |

45 row/min | 45 row/min | 45 row/min | 45 row/min | 45 row/min |

| Distance weft wires |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

| Distance warp wires |

130*3+160+18 0*3+200*2 (mm) |

89+89+101+114 +127+140+153+ 178+203+229+2 29 (mm) |

89+89+101+114 +127+140+153+ 178+203+229*3 (mm) |

100*13+150*2+ 200*2(mm) |

100*15+150*2+ 200*3(mm) |

| Line wire number |

10 | 12 | 13 | 18 | 21 |

| Weight | 3000KG | 3500KG | 3800KG | 4000KG | 4500KG |

| Dimensions | 3.0×3.0×2.4(m) | 3.2×3.0×2.4(m) | 3.4×3.0×2.4(m) | 3.6×3.0×2.4(m) | 3.9×3.0×2.4(m) |

| We can make machines according to customers’ requirements | |||||

Machine Feature

1. Special hole for line wire feeding, more flexible and tidy.

2. Instead of groove rail, we adopt linear rail to push cross wire, less resistance, moving fast.

3. Straightening rollers for weft wires, finished weft wire more straightened.

4. Pneumatic turning weft wire, more swift and flexible, to ensure high working speed.

5. Weft wire distance can be adjustable 50-500mm with the special device.

6. Cutter and Twisted head are made of hardened mold steel, life is at least one year.

7. Grid counter to record weaving roll length.

8. Mesh roller is easy to discharge and install.

9. Instead of electric-magnetic motor, we adopt frequency-variable motor controlled by inverter, adjustable working speed, saving 30%energy.

10. We adopt China top brand reducer, no oil leaking, life is at least 5 years.

11. Special sensor to detect cross wire feeding, if wire used up, the machine stops automatically.

specification

| Ineer wire diamerer |

1.8-2.5mm | 1.8-2.5mm | 1.8-2.5mm | 1.8-2.5mm | 1.8-2.5mm |

| Edge wire diameter |

2.0-3.5mm | 2.0-3.5mm | 2.0-3.5mm | 2.0-3.5mm | 2.0-3.5mm |

| Fence height | 1490mm | 1652mm | 1880mm | 2000mm | 2400mm |

| Produce efficiency |

45 row/min | 45 row/min | 45 row/min | 45 row/min | 45 row/min |

| Distance weft wires |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

50mm-500mm (Adjustable) |

| Distance warp wires |

130*3+160+18 0*3+200*2 (mm) |

89+89+101+114 +127+140+153+ 178+203+229+2 29 (mm) |

89+89+101+114 +127+140+153+ 178+203+229*3 (mm) |

100*13+150*2+ 200*2(mm) |

100*15+150*2+ 200*3(mm) |

| Line wire number |

10 | 12 | 13 | 18 | 21 |

| Weight | 3000KG | 3500KG | 3800KG | 4000KG | 4500KG |

| Dimensions | 3.0×3.0×2.4(m) | 3.2×3.0×2.4(m) | 3.4×3.0×2.4(m) | 3.6×3.0×2.4(m) | 3.9×3.0×2.4(m) |

| We can make machines according to customers’ requirements | |||||