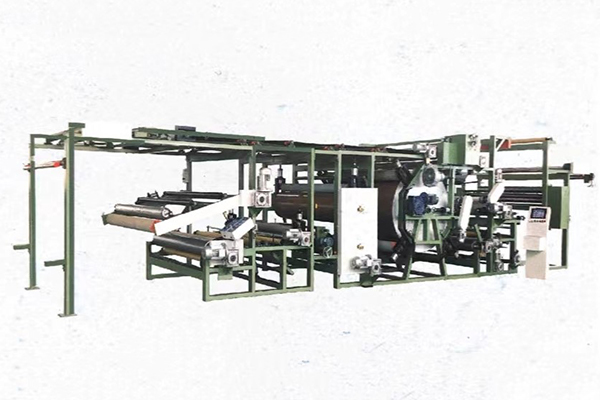

Gypsum Block Machine

Decorative Gypsum Block Production Line

The calcined natural gypsum powder first is sent to powder silo, the silo is with leveling instrument, etc. Then the powder enters into weighing silo, after measured by electronic scale, the materials enters into mixer through pheumatic valve. The water enters the mixer through water measuring device. Other additives can be added into mixer according to actual requirements.

In the mixer, the raw materials are mixed evenly with strong stirring, and then is automatically poured by hydraulic turning device into shaping machine’s mould cavities. At certain proper phase during the slurry setting, drive hydraulic shaping knife equipped above the mould cavities to move back-and-forth to scrape the top tenons of blocks. When slurry setting and hardening is completed, central hydraulic pressure station drives the lifting system of shaping machine to lift gypsum blocks in rows out from mould cavities. Then the gypsum blocks in rows are nipped, lifted and transported to stacking shelves by space clamp of shaping machine, then the blocks are conveyed to dryer for drying. The dryer system consists of drying kiln, circulation fan, circulation air pipeline, hot air stove, burner and regulation fan and trolleys. The kiln, circulation fan and circulation air pipeline is composed to be a complete hot air circulation system and hot air stove, burner and regulation fan can supplement with heat and fresh air; while the trolleys travel along the railway in the kiln, the hot air system will heat blocks and bring out the moisture in blocks. There equipped temperature detection devices in kiln to show air temperature at different part of kiln, which is convenient to control kiln accurately. When the blocks become dried, they are inspected and stored or delivery out of factory.

Capacity

100,000m2/y-450,000m2/y

Automation

Full automatic

Fuel: Natural gas, heavy oil, coal and diesel

Drying method

Dry by air

Hot air stove drying system

Main raw materials

Gypsum powder, water, additives

Product dimension

Thickness: 70mm-200mm

Width: 300mm-500mm( adjustable)

Length: 620mm,666mm

We can design and manufacture products of other dimensions as clients’special requirement

Standard of product quality

In conformity with national standard JC/T698-2010