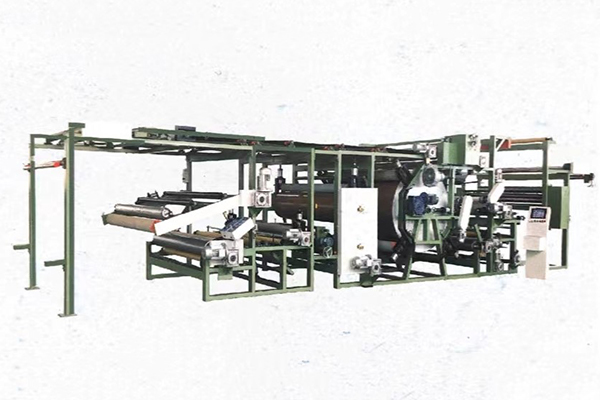

Gypsum Plasterboard Production Line

Advantage of Gypsum Plasterboard Production Line

After shaping, the boards are cut into required length by PLC servo controlled knife automatically. This knife can easily cut to be different lengths as preset in the PLC system. After cutting, the wet gypsum boards are detected and quick conveyed by speedup conveyor to 1# cross belt conveyor area, the waste boards are going out of the running line by its belt conveyor, and quality boards are lifting and turning over by inverter/turning machine, to turn the backside face to machine and face side upward, then grouped into two rows and then sent to tippler/distributor machine, which will distribute boards into different layers of dryer entry end automatically. This system is full automatically controlled by PLC. After dryer feeding, faceside of board is up to effectively prevent front side from potential damage during drying; to make full use of space and heat in the dryer more effectively.

China Gypsum Board Making Line Details:

1. Annual output:

4 million to 8 million sqm(based on thickness of 12.5mm gypsum board)

2. Working time: 24hours/day and 300 working days/year

3. Raw material: Gypsum plaster, paper, gypsum board starch, foam, WRA, glassfiber

4. Fuel: coal, natural gas, LPG, diesel, heavy oil

5. Product quality and specification:

1) The product is in compliance with National Standard GB/T9775-2008 or equivalent international standard

2) Product specification:

Length: 2400mm~3600mm

Width: 1200mm or 1220mm

Thickness: 9-15mm

6. Raw materials&energy consumption list(based on 12.5mm moisture resistant board)

| Item | Consumption |

| Gypsum powder(semi-hydrated gypsum CaSO4·1/2H2O) | 8.0kg/m2 |

| Moisture-resistance protective paper | 0.4-0.48kg/m2 |

| Gypsum board adhesive | 0.040kg/m2 |

| Foaming agent | 0.011kg/m2 |

| Silicone oil | 0.0012kg/m2 |

| Glue | 0.005kg/m2 |

| Electricity | 0.3kwh/m2 |

| Water | 4.5-4.8kg/m2 |

| Natural gas (8200 kcal/ m3) | 0.35 m3 /m2 |

| Compressed air | 0.18m3/m2 |

7. Main technology:

The production line adopts special designed direct hot air stove heating system or Duel fuel hot air stove system