Product Detail

Product Tags

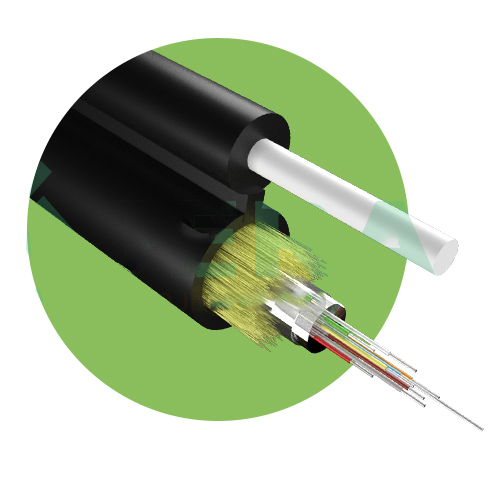

product details

Product Parameter

Product Features

● Durability

The H1Z2Z2-K DC PV Solar Cable is designed to withstand the harsh environmental conditions that solar power systems are exposed to. With its robust construction and high-quality materials, this cable offers exceptional durability, ensuring long-term performance and reliability. Whether it’s extreme temperatures, UV exposure, or mechanical stress, this cable is built to last, providing peace of mind for solar power system installers and owners.

● Reliability

When it comes to solar power systems, reliability is paramount. The H1Z2Z2-K DC PV Solar Cable delivers on this front, offering consistent and dependable performance in demanding solar energy applications. Its reliable insulation and conductive properties ensure efficient power transmission, minimizing the risk of system downtime and maximizing energy production. With this cable, users can trust that their solar power systems will operate reliably and efficiently for years to come.

● Versatility

The versatility of the H1Z2Z2-K DC PV Solar Cable makes it an ideal choice for a wide range of solar power system installations. Whether it’s rooftop solar arrays, ground-mounted systems, or solar farms, this cable can be easily integrated to meet diverse installation requirements. Its flexibility and ease of installation make it a versatile solution for various solar power applications, providing installers with the flexibility they need to design and implement efficient solar energy systems.

● Safety

Safety is a top priority in any electrical installation, and the H1Z2Z2-K DC PV Solar Cable is designed with this in mind. It meets stringent safety standards and regulations, offering reliable protection against electrical hazards. Its flame-retardant and low-smoke properties further enhance safety, reducing the risk of fire and minimizing the impact of potential incidents. With safety at the forefront of its design, this cable ensures a secure and reliable solar power system operation.

Product parameter

| Packing specification |

| PRODUCT NAME |

H1Z2Z2-K |

DOCUMEN NO |

-H1-003 |

| SIZE |

1×4mm² |

| STANDARD BASIS EN50618:2014 |

| MARKING |

PNTECH TUV EN50618:2014 H1Z2Z2-K 1×4mm² AC1.0/1.0KV DC1.5KV

ZHEJIANG PNTECH TECHNOLOGY CO.,LTD. |

| CONDUCTOR |

MATERIAL |

|

Tinned plated copper |

| CONSTRUCTION |

(N/mm) |

TS 56/0.285±0.015 |

| DIA |

(mm) |

2.4 |

| INSULATION |

MATERIAL |

|

XLPO |

| OVER DIAMEREDR |

(mm) |

3.8±0.1 |

| AVG. THICK |

(mm) |

≥0.7 |

| MIN. THICK |

(mm) |

≥0.53 |

| COLOR |

|

Upon customer’s request |

| SHEATH |

MATERIAL |

|

XLPO |

| OVER DIAMEREDR |

(mm) |

5.5±0.2 |

| AVG. THICK |

(mm) |

≥0.8 |

| MIN. THICK |

(mm) |

≥0.58 |

| COLOR |

|

Upon customer’s request |

| ELECTRICAL PERFORMANCE |

RATED VOLTAGE |

(V) |

AC1.0/1.0KV DC1.5KV |

| RATED TEMP |

(℃) |

-40℃-90℃ |

| COND. RESISTANCE |

(Ω/km,20℃) |

≤5.09 |

| INSU. RESISTANCE |

(MΩ.km,20℃) |

≥580 |

| VOITAGE WITH STAND TEST |

|

AC6.5KV或DC15KV,5min |

| SPARK ELECTROMECHANICAL VOLTAGE |

(KV) |

7 |

| SHORT-CIRCUIT TEMPERATURE |

|

≤200℃/5s |

| PHYSICAL PROPERTY OF INSULATION |

MIN TENSILE STRENGTH |

(N/mm²) |

≥8.0 |

| MIN BREAK ELONGATION RATE |

(%) |

≥125 |

| FLAME TEST |

|

EN60332-1-2 |

| THEORETICAL SERVICE LIFE |

|

25 |

| ENVIRON MENT PROECTION |

|

ROHS2.0 |

| Packing specification |

Packing quantity: 100m, 250m, 500m, 1000m, 2500m, 5000m |

Technical Data

| Use |

For Solar Plants Distribution System |

| Service Life |

25 Years (TUV) |

| Specification |

Standard |

| Origin |

China |

| Certification |

TUV |

| Product Name |

DC Solar PV Cable |

| Color |

Black ,Red ,Brown,Grey Or Customized |

| Specification1 |

1.5mm2, 2.5mm2, 4.0mm2, 6.0mm2, 10.0mm2, 16.0mm2, 25.0mm2, 35.0mm2 |

| Number of Cores |

Single Core |

| Transport Package |

Drum or Roll |

| Rated voltage |

AC:1.0/1.0KV DC:1.5KV |

| Voltage test on completed cable |

AC:6.5KV DC:15KV,5min |

| Ambient Temperature |

-40℃~+90℃ |

| Thermal endurance properties |

120℃,2000h,elongation at break≥50% |

| Pressuer Test At High Temperature |

EN60811-3-1 |

| Damp Heat Test |

EN60068-2-78 |

| ACID and Alkali resistance |

EN60811-2-1 |

| O-zone resistance at complete cable |

EN50396 |

| Thermal endurance test |

EN60216-2 |

| Cold bending test |

EN60811-1-4 |

| Sunlight resistance |

EN50289-4-17 |

| Test of vertical flame at complete cable |

EN60332-1-2 |

| Halogen content test |

EN60754-1/EN60754-2 |

| Approvals |

TUV SUD EN50618:2014 |

Specification

| Cross Section(mm²) |

Conductor Construction(Φn/mm±0.015) |

Conductor Stranded(Φmm±0.02) |

Cable OD(Φmm±0.02) |

Conductor DC Resistance(Ω/km) |

Carrying CapacityAT 60ºC(A) |

Packing(mater/roll) |

| 1×1.5 |

22×0.29 |

1.58 |

4.8 |

13.5 |

25 |

250 |

| 1×2.5 |

36×0.29 |

1.98 |

5.5 |

8.21 |

36 |

100/250/500 |

| 1×4.0 |

56×0.29 |

2.35 |

5.8 |

5.09 |

44 |

100/250/500/5000 |

| 1×6.0 |

84×0.29 |

3.06 |

6.6 |

3.39 |

60 |

100/200 |

| 1×10 |

80×0.4 |

4.6 |

8 |

1.95 |

82 |

100 |

| 1×16 |

120×0.4 |

5.6 |

10 |

1.24 |

122 |

100 |

| 1×25 |

196×0.4 |

6.95 |

12 |

0.795 |

160 |

100 |

| 1×35 |

276×0.4 |

8.3 |

13 |

0.565 |

200 |

100 |

Previous:

High Precision Self-flow Filling Machine

Next:

DBB Carbon Steel Fixed Ball Valve