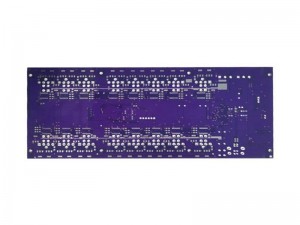

Heavy Copper Printed Circuit Boards

What is a heavy copper PCB?

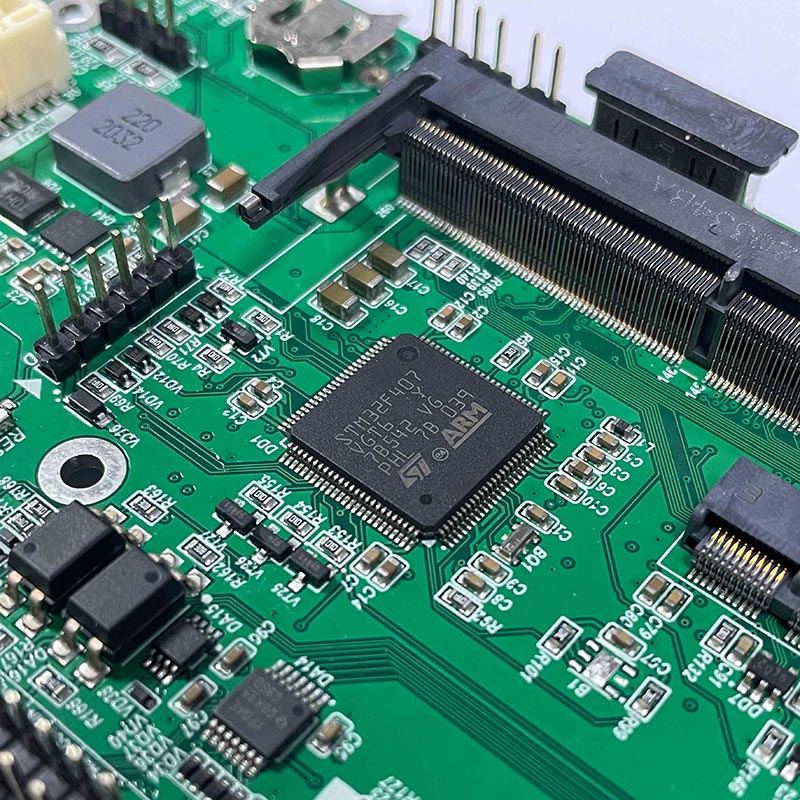

Double-sided printed boards are usually made of epoxy glass cloth copper foil. It is mainly used for communication electronics with high performance requirements Equipment, advanced instruments and electronic computers, etc.

Heavy copper PCBs are defined as boards with:

Common heavy copper weights:

Other key attributes:

.section-block-demo39-advantage1 { position: relative; padding: 3.5rem 0; } .section-block-demo39-advantage1 .advantage-items { padding: 2rem 0; display: flex; flex-wrap: wrap; } .section-block-demo39-advantage1 .advantage-item { position: relative; padding: 10px; } .section-block-demo39-advantage1 .item-order { position: absolute; top: 2.2rem; right: 2.5rem; font-size: 5.3rem; font-weight: 700; line-height: 1; color: #ffffff; opacity: 0; letter-spacing: 2px; text-shadow: var(–bs-theme-color) 1px 0 0, var(–bs-theme-color) 0 1px 0, var(–bs-theme-color) -1px 0 0, var(–bs-theme-color) 0 -1px 0; } .section-block-demo39-advantage1 .item-inner:hover .item-order { opacity: 1; } .section-block-demo39-advantage1 .item-inner { position: relative; display: block; width: 100%; height: 100%; padding: 2.7rem; background-color: #f7f9ff; border: 1px solid var(–bs-sec-theme-color); z-index: 1; } .section-block-demo39-advantage1 .item-inner::after { content: ”; width: 100%; height: 100%; position: absolute; top: 0; left: 0; z-index: -1; pointer-events: none; background-color: #ffffff; } .section-block-demo39-advantage1 .item-inner:hover { border-color: transparent; } .section-block-demo39-advantage1 .item-inner:hover::after { opacity: 0; } .section-block-demo39-advantage1 .item-inner .item-ico { height: 58px; } .section-block-demo39-advantage1 .item-inner .item-info { padding-top: 2rem; } .section-block-demo39-advantage1 .item-inner .item-title { margin: 0 0 1rem; font-size: 2.5rem; font-weight: 700; } .section-block-demo39-advantage1 .item-inner .item-desc { font-size: 1.28rem; line-height: 1.33; color: #65605f; } .section-block-demo39-advantage1 .item-inner, .section-block-demo39-advantage1 .item-order { -webkit-transition: all .4s ease; transition: all .4s ease; } @media only screen and (max-width:1280px) { .section-block-demo39-advantage1 .item-order { font-size: 4.2rem; } .section-block-demo39-advantage1 .item-inner .item-title { font-size: 2rem; } } @media only screen and (max-width:992px) { .section-block-demo39-advantage1 .item-inner { padding: 1.5rem; } .section-block-demo39-advantage1 .item-order { top: 1.2rem; right: 1.5rem; } .section-block-demo39-advantage1 .advantage-item { padding: 5px; } } @media only screen and (max-width:768px) { .section-block-demo39-advantage1 .item-inner { padding: 1.2rem; } .section-block-demo39-advantage1 .item-inner .item-title { font-size: 1.5rem; } .section-block-demo39-advantage1 .item-inner .item-desc { font-size: 1.1rem; } } @media only screen and (max-width:576px) { .section-block-demo39-advantage1 { padding: 1rem 0; } .section-block-demo39-advantage1 .item-order { font-size: 3.5rem; } }

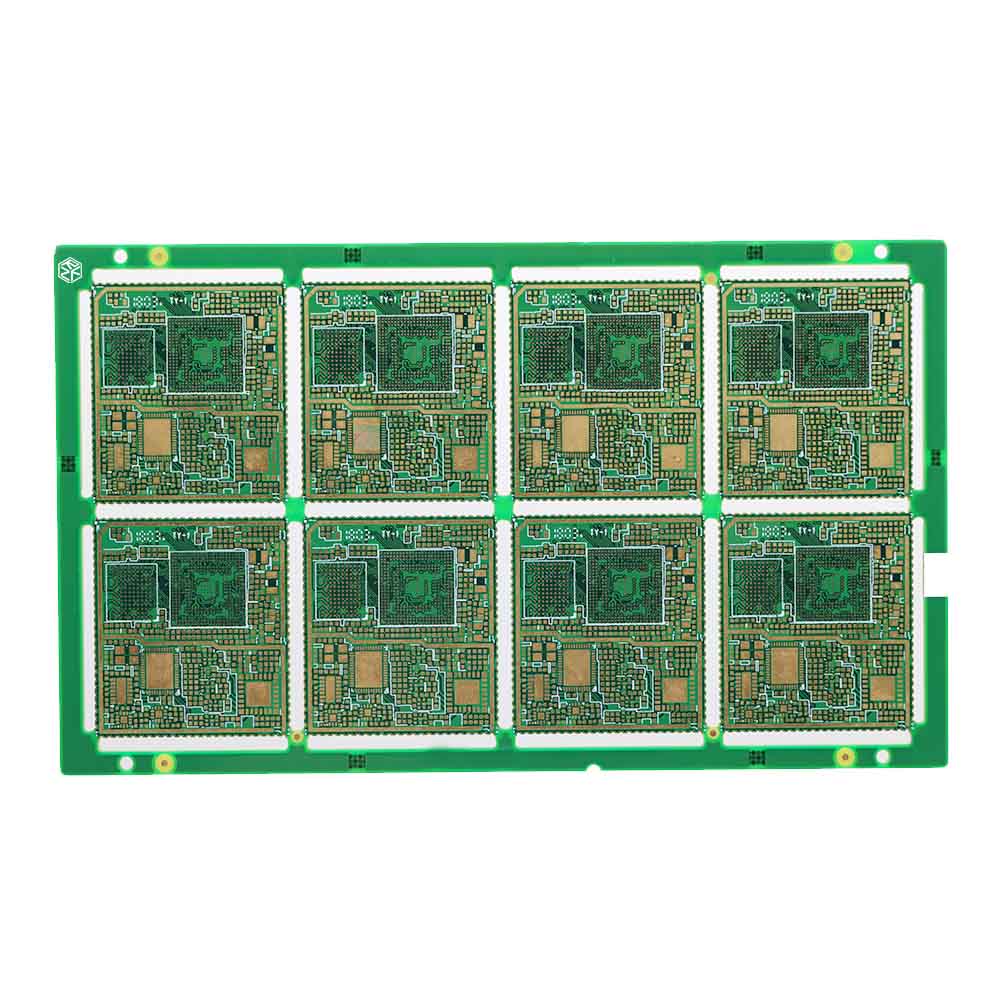

| Feature | AREX´s technical specification |

| Number of layers | 4 – 22 layers standard, 30 layers advanced, 40 layers prototype, much depending on copper thickness. |

| Technology highlights | Multiple layers of epoxy glass fiber bonded together with multiple layers of copper of varying thicknesses. |

| Materials | High performance FR4, halogen-free FR4 |

| Copper weights (finished) | 18-210µm, advanced 1050µm / 30 Oz |

| Minimum track and gap | 0,075mm / 0,075mm (very much depending on copper thickness) |

| PCB thickness | 0.40mm – 7.0mm, Min thickness depending on number of layers and copper thickness |

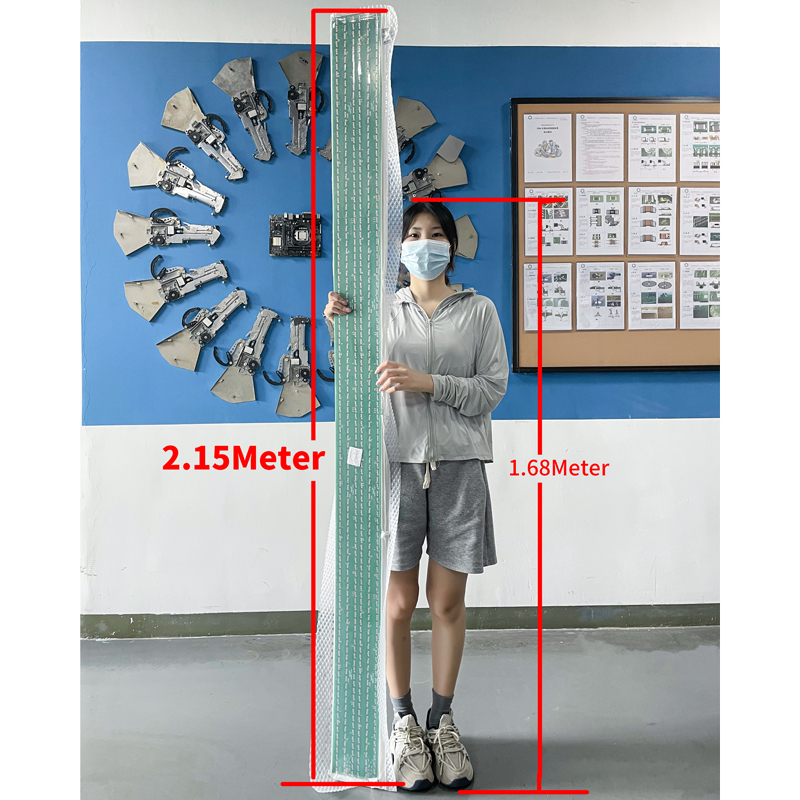

| Maxmimum dimensions | 580mm x 1080mm, advanced 610mm x 1400mm |

| Surface finishes available | HASL (SnPb), LF HASL (SnNiCu), OSP, ENIG, Immersion Tin, Immersion Silver, Electrolytic gold, Gold fingers (HASL / LF HASL not recommended) |

| Minimum mechanical drill | 0.20mm |

.section-block-demo1-productDetail1 .tab-nav { border-bottom: 1px solid #eee } .section-block-demo1-productDetail1 .nav-item { font-size: 1.4rem; border: 1px solid #eee; border-bottom: none; border-radius: 5px 5px 0 0; margin: 0 10px 0 0; padding: .5rem 1rem; } .section-block-demo1-productDetail1 .nav-item.active { background-color: var(–bs-theme-color); color: #fff; } .section-block-demo1-productDetail1 .tab-pannel-wrap { padding: 2rem 0; }