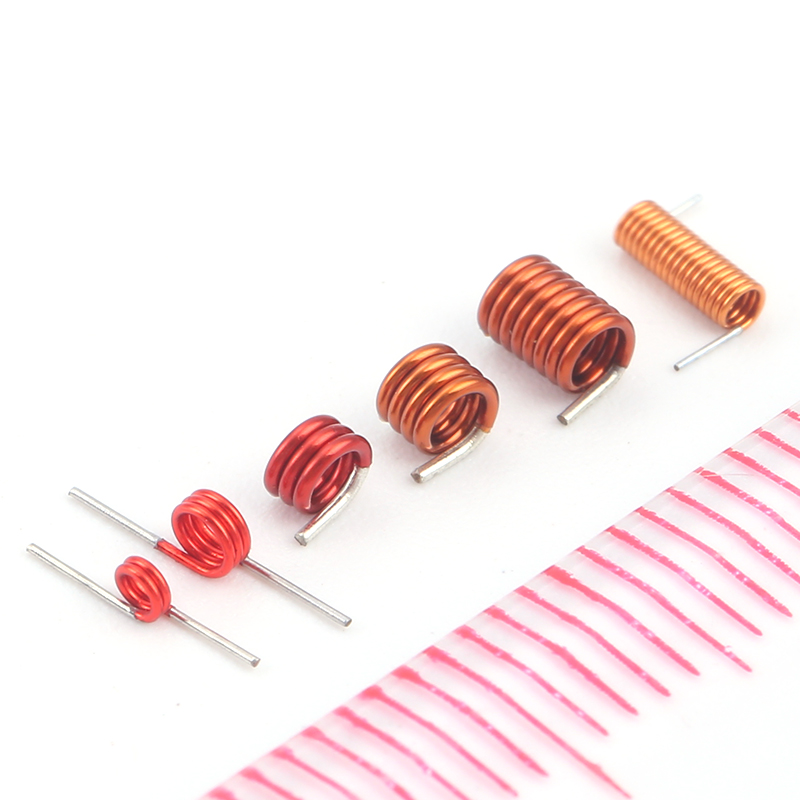

High Current Flat Coil Inductors

product video

product Description

1、We make customized production according to the requirements of drawings or samples.

2、We have many kinds of material specifications, we can provide you with the specification and dimensions table of the wire, and all the raw materials are strictly inspected;

3、You can refer to our product album, we have many successful cases, the experience of engineers is vital to the development of the product, the design of the mould and the debugging process also affects the stability of the product, the details are well handled to prevent the damage of the insulation layer;

4、Advanced automatic equipment, can guarantee the high efficiency, can send the products you need on time;

5、If the ratio of the width and thickness of your product wire is less than 4:1, we can adopt the mechanical way to peel the enamel, to achieve fully automatic production and improve production efficiency;

6、During the mass production, we will collect parts and check the appearance and size of products regularly, and record and archive;

7、We will monitor the quality of every production process of the products, and we will check all the products before shipment;

8、We will test the reliability of the packaging repeatedly to confirm that it will not be damaged during transit;

Product Applications

High-power flat copper wire coil inductors are often used in products that require high power transmission and efficient energy conversion. For example, they can be used for power transmission of industrial equipment, high-power charging equipment, electric vehicle charging systems, wireless energy transmission systems, etc. These products typically require higher power density and efficiency.

Product Dispaly

description2

.section-block-demo1-productDetail1 .tab-nav { border-bottom: 1px solid #eee } .section-block-demo1-productDetail1 .nav-item { font-size: 1.4rem; border: 1px solid #eee; border-bottom: none; border-radius: 5px 5px 0 0; margin: 0 10px 0 0; padding: .5rem 1rem; text-transform: capitalize; } .section-block-demo1-productDetail1 .nav-item.active { background-color: var(–bs-theme-color); color: #fff; } .section-block-demo1-productDetail1 .tab-pannel-wrap { padding: 2rem 0; }

product video

product Description

1、We make customized production according to the requirements of drawings or samples.

2、We have many kinds of material specifications, we can provide you with the specification and dimensions table of the wire, and all the raw materials are strictly inspected;

3、You can refer to our product album, we have many successful cases, the experience of engineers is vital to the development of the product, the design of the mould and the debugging process also affects the stability of the product, the details are well handled to prevent the damage of the insulation layer;

4、Advanced automatic equipment, can guarantee the high efficiency, can send the products you need on time;

5、If the ratio of the width and thickness of your product wire is less than 4:1, we can adopt the mechanical way to peel the enamel, to achieve fully automatic production and improve production efficiency;

6、During the mass production, we will collect parts and check the appearance and size of products regularly, and record and archive;

7、We will monitor the quality of every production process of the products, and we will check all the products before shipment;

8、We will test the reliability of the packaging repeatedly to confirm that it will not be damaged during transit;

Product Applications

High-power flat copper wire coil inductors are often used in products that require high power transmission and efficient energy conversion. For example, they can be used for power transmission of industrial equipment, high-power charging equipment, electric vehicle charging systems, wireless energy transmission systems, etc. These products typically require higher power density and efficiency.

Product Dispaly

Write your message here and send it to us