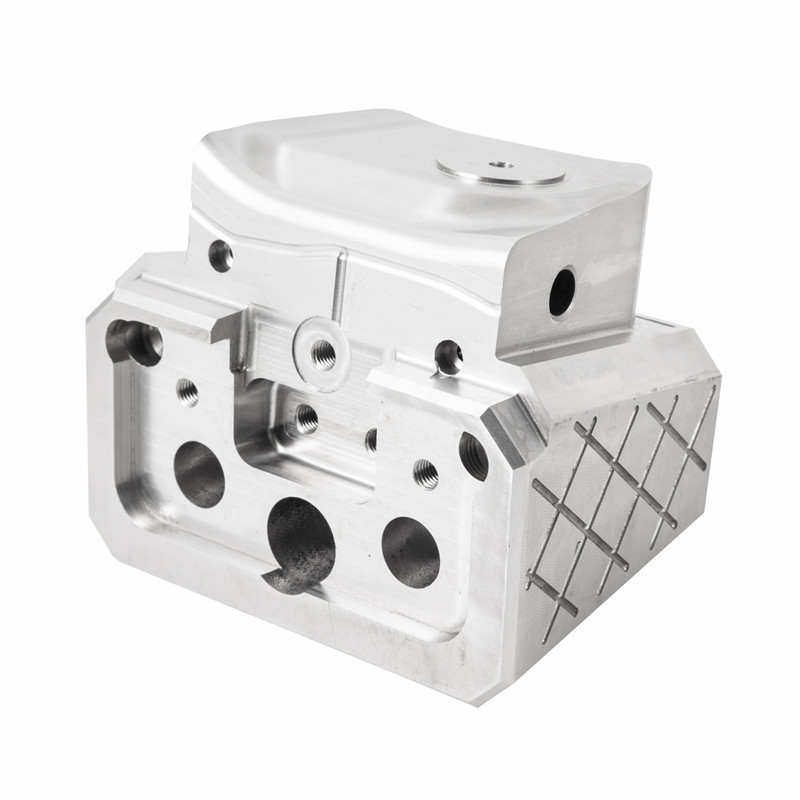

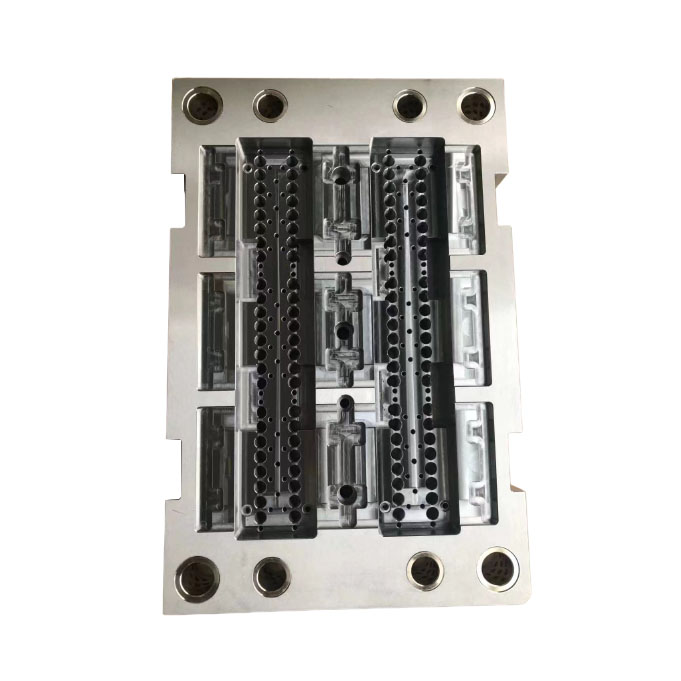

High precision slider for die casting mold and injection mold

Material / Steel

Kunshan BCTM can provide very cost-effective local material with very excellent performance, which has gain all of our customers‘ recognition. We also can provide the imported steel from different brands all over the world, such as ASSAB, Schmiedewerke Gröditz, Hitachi Metals, Schmolz+Bickenbach, Finkl Steel, Scana, Crucible, Posco, Doosan, Daido Steel, Koshuha Steel, Sanyo Steel, Nachi, Sinto, Saarstahl, Buderus, Kind & Co, Aubertduval, Erasteel, Sorel forge, etc.

Production

We have world-class machines to do milling, grinding, CNC machining, EDM, wire-cutting, high-speed milling, etc. Our quality is very good and stable. Besides the state-of-art machines, we have the experienced technology team and production team. All of them have at least 18 years of working experience. They can quickly and clearly get customer’s requirements. Their rich experience can help customer solve have won the recognition from our customers.

The types of production:

CNC Equipment: High speed CNC vertical M/C’s.

Sink EDM’s.

Wire EDM’s.

Various manual machine tools.

CNC lathes.

Spotting press.

Surface grinders.

Detail Drawing

Soft We Use

UG, AUTO CAD

Tool Design

Kunshan BCTM Co., Ltd. utilizes a multi-disciplinary approach to tool designs including our tooling specialists, tool designer and process specialists.

• Tool design verification utilizing Mold flow simulation software for die filling, part thermos and FEA analysis.

• Reverse engineering of tooling to create design in solids format.

• CAD: Unigraphics, AutoCad, Mold flow software.

Inspection

Quality Equipment

Coordinate Measuring Machine with CAD interface.

Shadowgraph.

Hardness tester.

Plug and Thread gauges.

Quality System Implementation

• Quality System Implementation, including ISO 90012005 documenting the Quality Manual, Procedures and Work Instructions.

• Project Management through Customer requirements.

• Provide dimensional reports as required by Customers.

• Provide Material certifications as required by Customers.

• In –process and final inspections prior packaging and shipping.

When material arrives at factory, we will check the hardness, flaw detection, dimension and other items to make sure everything is correct. We implement the process inspection to try to find issues as early as possible to save time and avoid bigger cost lose. After production finished, we will provide CMM report.