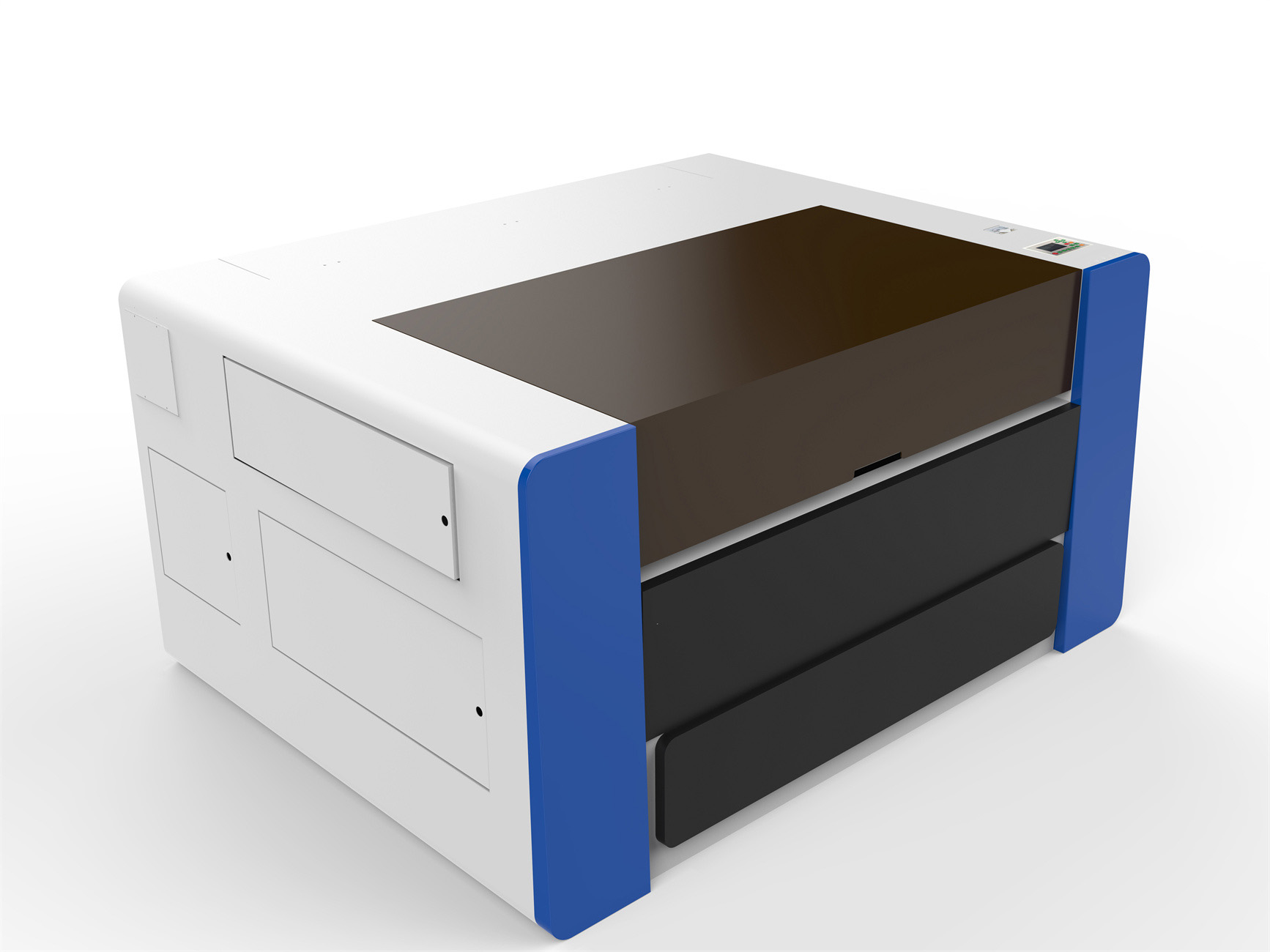

Horizontal Machining Center HMC-63W

Horizontal milling machine It can realize drilling, milling, boring, expanding, reaming, tapping and other complex parts under one clamping for complex parts such as various discs, plates, shells, cams, and molds. Two lines and one hard structure , suitable for single-piece and mass production of various complex parts in various industries.

Product use

Horizontal machining center, widely used in automotive, aerospace, general machinery and other industries

Horizontal machining center. Most suitable for processing large strokes and complex precision parts

Horizontal machining center, suitable for multi-working surface and multi-process processing of parts

Horizontal machining centers are widely used in complex parts. Surface and hole processing.

Horizontal machining centers are widely used in complex parts. Surface and hole processing.

Product casting process

CNC Horizontal machining center, the casting adopts Meehanite casting process, and the label is TH300.

Horizontal milling machine, table cross slide and base, to meet heavy cutting and rapid movement

Horizontal milling machine, the inner part of the casting adopts double-walled grid-shaped rib structure.

Horizontal milling machine, the bed and columns fail naturally, improving the precision of the machining center.

Horizontal machining center, optimized design for five major castings, reasonable layout

Boutique Parts

Precision assembly inspection control process

Workbench Accuracy Test

Opto-Mechanical Component Inspection

Verticality Detection

Parallelism Detection

Nut Seat Accuracy Inspection

Angle Deviation Detection

Configure brand CNC system

TAJANE Horizontal machining center machine tools, according to customer needs, provide various brands of CNC systems to meet customers’ different needs for vertical machining centers, FANUC, SIEMENS, MITSUBISH, SYNTEC。

Fully enclosed packaging, escort for transportation

Fully enclosed wooden packaging

Horizontal Machining Center HMC-63W, fully enclosed package, escort for transportation

Vacuum packaging in the box

Horizontal Machining Center HMC-63W, with moisture-proof vacuum packaging inside the box, suitable for long-distance long-distance transportation

Clear mark

Horizontal Machining Center HMC-63W, with clear markings in the packing box, loading and unloading icons, model weight and size, and high recognition

Solid wood bottom bracket

Horizontal Machining Center HMC-63W, the bottom of the packing box is made of solid wood, which is hard and non-slip, and fastens to lock the goods