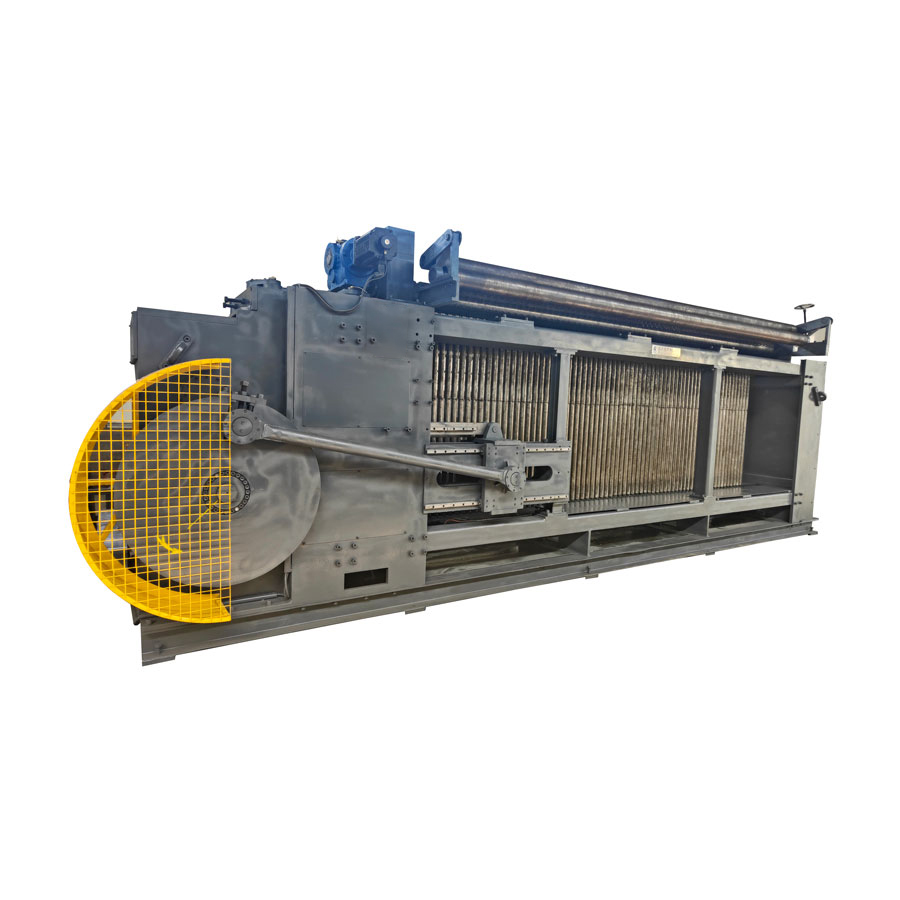

HP-DMH Series Dry Material Preheater

Technical Performance

1. High preheating quality

It adopts tangent and differential mixing blade dry material mixing and heating technology,by which materials constantly contact heat transmission surface of equipment directly to realize efficient mixing and heating.

2.Fast heat transmission and high temperature

Adopt efficient high temperature tank patent technology (invention patent number: ZL201210124643.8), new type mixing blade patent technology(Patent No.: ZL 201610897074.9、ZL201610897263.6),overall heating patent technology (invention patent number: ZL200420018996.0),mixing blade heating patent technology (patent number: ZL200620085174.3),discharge gate heating technology lining plate and tank seamless fitting technology.

3. Guarantee dry material particle size proportion

Use special equipment to process the inner diameter of tank and bearing hole of tank end plate, the high machining precision guarantees gap requirement between mixing blade and tank and prevents particles from grinding during mixing and heating.

4. Temperature measurement is accurate

Adopt new temperature measuring technology (patent No.: ZL201420490132.2) to improve temperature measuring performance of thermo-responsive and anti-interference.

5. Perfect air tightness

Adopt combined overlapping metal ring to form multiple sealing(patent number:ZL 2014 2 0490187.3) to guarantee no carbon powder leakage from shaft end of mixing blade; Hydraulic rotary lock discharge gate has excellent air tightness, sealing surface of which will never wear out that air tightness is reliable with no material leakage from discharge gate.

6. Fast discharge, no material residue

Mixing blades push material spirally to discharge fast. Material is discharged out completely from bottom discharge gate in less than 2min without residue left.

7. No powder leakage during material dis- charge

Sealing hopper seals discharge door completely, no powder is leaked during material discharge. All draulic executive mechanisms of discharge door are set outside of sealing hopper for convenient observation and maintenance.

8. High wear-resistance lining plate

Mixing blade is surface-welded with wear-resistant layers, rigidity of which is up to HRC665, and service life of mixing blade is 20 years. New type wear-resistant manganese steel material is used as lining plates with high strength after thermal treatment. Service life of lining plates for anode production is 15 years and 1 year it is for cathode and carbon electrode production.

9. Mixing blade structure suitable to high temperature work environment

Bearing moves when mixing blade stretches longer under heat to avoid bearing blockage caused by mixing blade stretching longer. Bearing chamber has cooling structure which guarantees normal work temperature of bearing and it extends service life of bearing Bearing chamber has cooling water jacket to guarantee work temperature of bearing under high temperature and extend its service life. Mixing blades run normally under high temperature.

10. Reliable operation of transmission system

Transmission system is composed of master motor, P series hard teeth reduction gear, bearing capacity of which is 3 times that of common teeth reduction gear, so that equipment will not be damaged in case of foreign hard things falling inside the tank and blocking mixing blades.

11. Low noise

It is machined by special equipment, it has good concentricity, the operation is smooth, service life is long, and operation noise of the entire machine is less than 80dB.

12.PLC full automatic control

PLC control and internet communication s adopted to measure display and transmit equipment running and status parameters at real time (optional configuration). Three kinds of operation mode–internet automatic, single machine automatic and manal–guarantee the machine itself can run automatically no matter if upstream and downstream machines are automatic.