HSS DIN345 Morse Taper Shank Drills

Product description

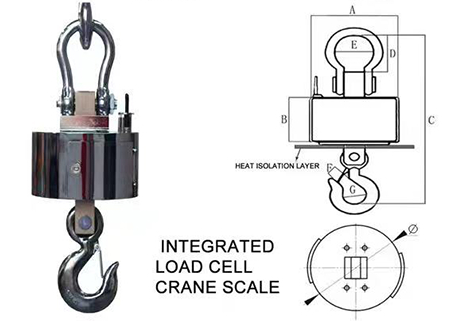

Taper shank twist drill is the most widely used tool for hole machining, usually with a diameter of 0.25 to 80 millimeters. It is mainly composed of working parts and shank parts. The working part has two spiral grooves, shaped like a twist, hence its name. Unlike the straight shank twist drill, the taper shank twist drill part has taper. Different specifications of twist drill have different Morse taper.

Tapered shank twist drill is widely used in the processing of finished products and semi-finished products as a common tool for hole machining. According to statistics, more than half of high speed steel cutters produced annually are bits, and taper shank twist drills occupy a certain number. Therefore, it is necessary to further analyze the processing technology and processing methods of taper shank twist drills.

Features

1.Precise dimension,long life and high efficiency.

2.High-speed steel (HSS) provides hardness for wear resistance

3.Black oxide finish reduces wear while promoting chip and coolant flow on ferrous materials

4.Self-centering 118-degree notched point penetrates material without a pilot hole more easily than a conventional point, and maintains a sharp cutting edge

5.Morse taper shank allows the tool to be inserted directly into the machine’s spindle to facilitate high-torque applications such as large cut diameters

6.When run in a counterclockwise direction (right-hand cut) spiral fluted tools evacuate chips up and out of the cut to reduce clogging

7.Designed to perform in a broad range of materials in the iron and steel families

8.Spiral flutes are constructed with a higher flute angle to remove chips more easily.

Product description.

OUR ADVANTAGES

High quality twist drill HSS Morse Taper Shank drill for steels

1.Low MOQ: It can meet your business very well.

2.OEM Accepted : We can produce any your design box(your own brand not copy).

3.Good Service : We treat clients as friend.

4.Good Quality :We have strict quality control system .Good reputation in the market.

5.Fast & Cheap Delivery: We have big discount from forwarder (Long Contract).

The manufacturing methods of high speed steel (W6Mo5Cr4V2) twist drill can be divided into rolling, twisting, milling, extruding, rubbing, rolling and grinding. Among them, four methods of rolling, twisting, milling, rolling and grinding are more common.