Injection molding service

How Does Injection Molding Work?

Star Machining offer a complete manufacturing solution that covers every aspect of raw material verification, tool making, part fabrication, finishing, and final inspection. Our team of manufacturing experts is committed to providing you with the highest level of professional support for plastic injection molding services of any size or complexity.

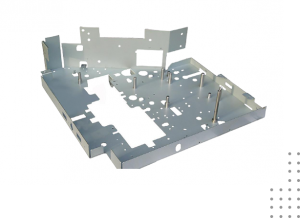

Normally injection mold manufacturing can be roughly divided into the following steps:

1. Process analysis of plastic products:

Before the mold design, the designer should fully analyze and study whether the plastic product conforms to the injection molding processing principle, and needs to negotiate with the product designer carefully, and a consensus has been reached. Including the geometric shape, dimensional accuracy and appearance requirements of the product, necessary discussions, try to avoid unnecessary complexity in mold manufacturing.

2. Mould structure design.

3. Determine the mold material and select standard parts.

In the selection of mold materials, in addition to considering the accuracy and quality of the product, the correct choice must be made in combination with the actual processing and heat treatment capabilities of the mold factory. In addition, in order to shorten the manufacturing cycle, use existing standard parts as much as possible.

4. Parts processing and mold assembly.

5. try out the molds.

A set of molds only completes 70% to 80% of the entire manufacturing process from the beginning of the design to the completion of assembly. The error caused by the inconsistency between the predetermined shrinkage and the actual shrinkage, the smoothness of demolding, and the cooling effect, especially the influence of the size, position, and shape of the gate on the accuracy and appearance of the product, must be tested by mold trials. Therefore, mold trial is an indispensable step to check whether the mold is qualified and select the best molding process.

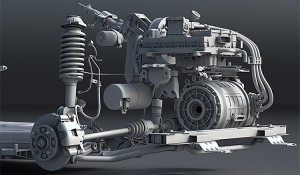

Injection Molding Applicatons

Injection molding is used for making complex shape parts of various sizes having less wall thickness. Typical parts like cup, containers, toys, plumbing fittings, electrical components, telephones receivers, bottle caps, automotive parts and components.