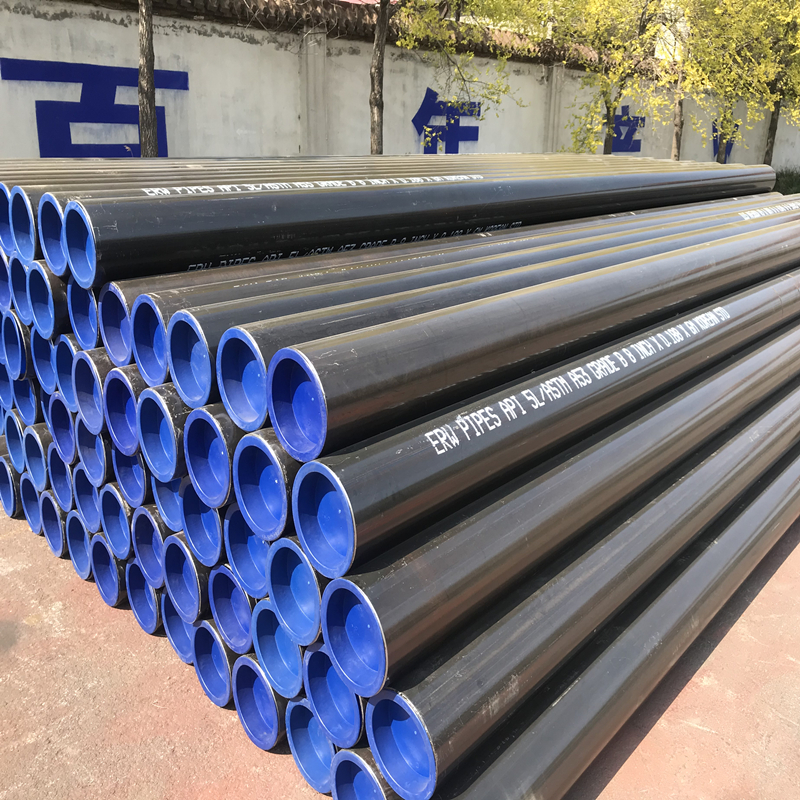

JIS G3454 Carbon ERW Steel Pipe pressure service

| Style | Technical | Material | Standard | Grade | Usage |

| Electric Resistance Welded (ERW) steel pipe | High Frequency | Carbon Steel | API 5L PSL1&PSL2 | GR.B,X42,X46,X52,X60,X65,X70,etc | Transportation of oil and gas |

| ASTM A53 | GR.A ,GR.B | For Structure (Piling) | |||

| ASTM A252 | GR.1, GR.2,GR.3 | ||||

| BS EN10210 | S275JRH,S275J0H,S355J0H,S355J2H,etc | ||||

| BS EN10219 | S275JRH,S275J0H,S355J0H,S355J2H,etc | ||||

| JIS G3452 | SGP,etc | Transportation of Low-pressure fluid | |||

| JIS G3454 | STPG370,STPG410,etc | Transportation of High-pressure fluid | |||

| JIS G3456 | STPG370,STPG410,STPG480,etc | high temperature steel pipes |

Pipe ordered under this specification is for pressure service at an approximate maximum temperature of 350℃。

Bare pipe, black coating or hot dip zinc-coated( customized);

In bundles with two cotton slings;

Both ends with end protectors;

Plain end, bevel end(When required by the purchaser and S≤22mm, the pipe end of should be bevelled, degree: 30° (+5°~0°), and the wall thickness of the root is not reduced by <2.4mm.);

Marking.

Pipe End Protection

Marking on Pipes

Marking on Pipes

Grade and Chemical Composition (%)

|

Grade |

C≤ |

Si≤ |

Mn |

P≤ |

S≤ |

|

STPG370 |

0.25 |

0.35 |

0.30~0.90 |

0.040 |

0.040 |

|

STPG410 |

0.30 |

0.35 |

0.30~1.00 |

0.040 |

0.040 |

|

|

|

|

|

|

|

|

Mechanical Properties |

||||||

|

Grade |

Tensile strength |

Yield strength |

Elongation % |

|||

|

N/ m㎡ |

N/ m㎡ |

No.11 or No.12 test pieces |

No. 5 test pieces |

No. 4 test piece |

||

|

|

|

Longitudinal |

Transverse |

Longitudinal |

Transverse |

|

|

STPG370 |

370 min |

215 min |

30 min |

25 min |

28 min |

23 min |

|

STPG410 |

410 min |

245 min |

25 min |

20 min |

24 min |

19 min |

Tolerance of OD and W.T

|

Division |

Tolerance on O.D |

Tolerance on W.T |

||

|

Cold finished ERW Steel Pipe |

24A or under |

+/-0.3mm |

Under 3mm

3mm or over |

+/-0.3mm

+/-10% |

|

32A or over |

+/-0.8% |

|

|

|

| For pipes of nominal size 350A or over,the tolerance on O.D maybe determined by the circumferential length. In this case,the tolerance shall be +/-0.5% | ||||