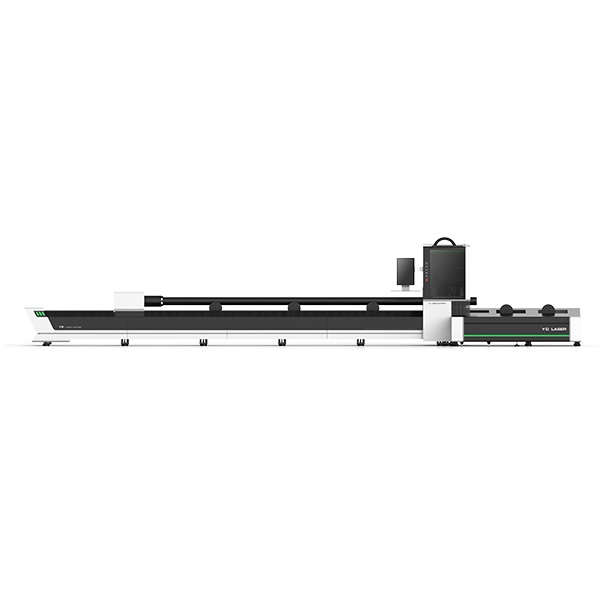

laser Q series laser cutting machine, pipe processing machine.

Products Descriptions

With the continuous development and maturity of laser technology, especially the rapid development of NC laser cutting machine equipment in recent years, it is widely used in sheet metal, steel structure, auto parts, packaging and other industries. CNC laser cutting machine has obvious advantages: fast cutting speed, good quality and high precision; The cutting surface is smooth and does not damage the workpiece; It is not affected by the shape of the workpiece and the hardness of the material to be cut; Simple operation, safety, stable performance, wide adaptability and flexibility. With the growth of metal pipe processing in China, in order to meet the needs of the industrial market, various pipe laser pipe cutting machines are widely used in the metal processing industry. The pipe laser cutting machine fully meets the cutting needs of users for the professional, stable and efficient cutting effect of pipes. The Q series products of laser are clamped by high-precision chuck. The chuck is driven by servo motor synchronous belt. It has a special system and integrated operation process, which is suitable for diversified cutting of various pipes.

Proudcts Features & Advantage

1. Wide range of materials: laser cutting can be used for carbon steel cutting, stainless steel cutting, alloy steel cutting, aluminum and alloy material cutting, etc

2. Perforation, complex contour and long pipe machining can be realized through simple operation.

3. High cutting efficiency and mass production can be realized.

4. The incision is flat, without burr, with fine cutting seam and less material loss, which can save at least 15% ~ 30% material loss.

5. Non contact processing, and the heat affected zone of laser cutting is very small, almost no deformation.

6. The cutting accuracy is high, and the contour accuracy can reach ± 0.05mm.

7. Full automatic self centering pneumatic chuck.

8. Welded bed, integrally cast aluminum beam, stable structure and accurate positioning.

9. Professional cutting software to achieve high-precision processing of pipes.