Liquid metal with luxury jewelry watch shell

Product Introduction

At SIHH 2017, Panerai released Luminor Submersible 1950 BMG-TECH™. The biggest highlight of this watch is the use of BMG-TECH™. Panerai calls BMG-TECH™ “Stronger Than Nature”, which is [an invisible but extremely revolutionary innovative technology. It is the result of Panerai's continuous research on design and new materials: the first completely Case made with BMG-TECH™]

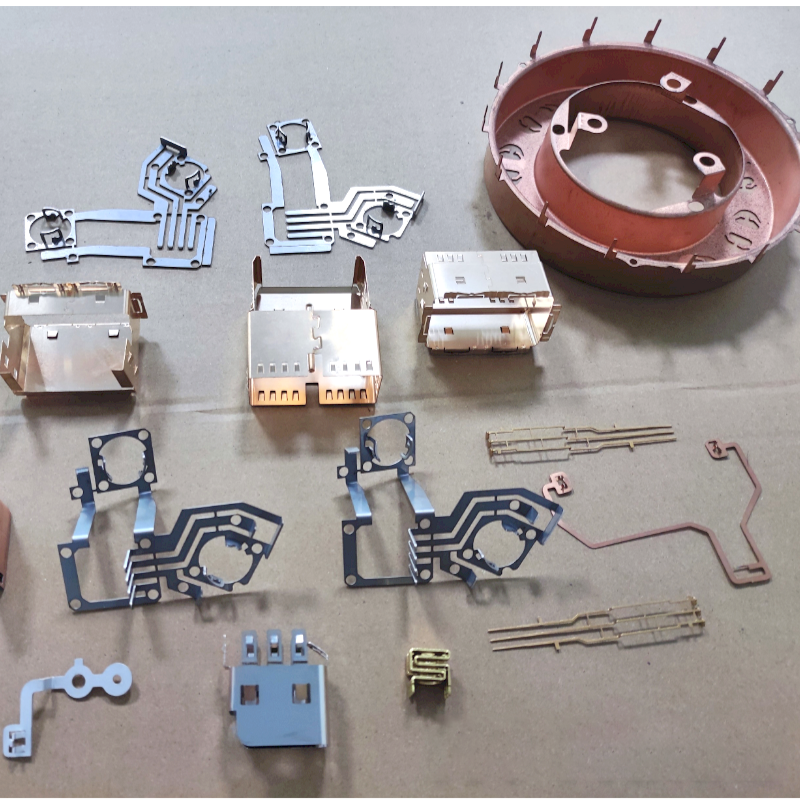

Product Display

Amorphous metal is already popular with well-known watch brands, and this material is fully capable of meeting the requirements of top-of-the-line watches. Of course, with the rise of smartwatches, the use of amorphous metal materials as smartwatch housing is also increasing.

Amorphous metal is proven to be the best choice for housing materials

*Elasticity, strength and hardness

*Anti-corrosive

*High wear resistance

More importantly, amorphous metal housings are processed differently from conventional metals. The first step was not to machine, but to form the shape of the case by injection molding.

Differences in processing will give components the following advantages, which are unmatched:

·Meet the manufacturing requirements of complex structural parts, and have good dimensional accuracy and stability;

·For precision structures that CNC cannot do, such as sharp glossy edges;

·Products are molded, dimensional stability and tolerance consistency is guaranteed by mold accuracy.

·High accuracy: linear tolerance: ±0.03 mm; flatness <0.15 mm parallelism tolerance <0.05 mm;

·High strength, high hardness come with parts once molded, post processing will not affect products’ dimensional stability

·Parts are formed net shape and cost less than CNC

Amorphous metal injection molding itself has a good surface finish, which gives the amorphous metal housing a relatively simple post-process, amorphous metal can fully copy the finish and texture of the mold surface. Fine mold surface finish can be as small as Ra0.2um. For any other manufacturing methods, such surface finish cannot be achieved without secondary processes such as ultra-finishing, grinding or polishing.

Full replication of the mold’s finish is unique to amorphous materials and cannot be achieved by other metals.

Product Display