Low Voltage PVC Insulated Power Cable

Application

PVC insulated cable is suitable for electric line distribution and power transmission with rated voltage 0.6/1kV.

The pvc insulated armoured cable could bear certain external mechanical forces and pulling forces that is widely used in tunnel, railway, underground, and large drop height etc. While the pvc insulated unarmoured cable wouldn’t bear external mechanical forces and it is mainly laid in indoor, in cable trench, in tunnel, buried in soil etc.

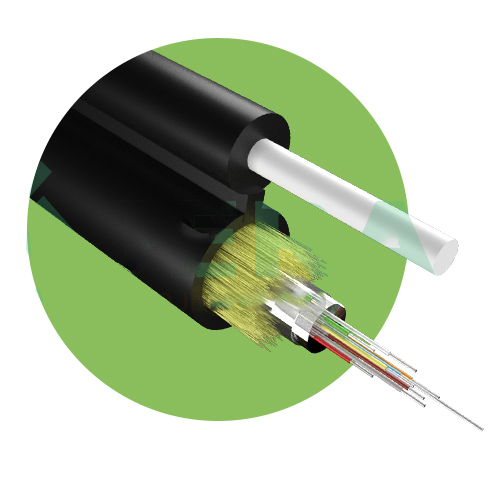

Constrution

Characteristics

1. The long working temperature of pvc cable should not be higher than 70℃.

2. The temperature should not exceed 160℃ in short-circuit (max. 5s).

3. The ambient temperature should not be lower than 0℃ otherwise the cable should be preheated when installed.

4. The bending radius should not be less than 10 times of outer diameter of cable when installed.

5. The cable should withstand voltage test for 15minute 3.5kV d.c after installation.

Standards

International: IEC 60502, IEC 60227 IEC 60331, IEC 61034

China: GB/T 12706-91 GB306.1-2001, GB/T18380.3-2001

Other standards such as BS,DIN and ICEA upon request

Parameters

| conductor size | thickness of insulation | thickness of sheath | approx outer diameter | ||||||||

| mm | mm | ||||||||||

| mm2 | mm | 1core | 2core | 3core | 4core | 5core | 1core | 2core | 3core | 4core | 5core |

| 1.5 | 0.8 | 1.4 | 1.8 | 1.8 | 1.8 | 1.8 | 5.8 | 10.4 | 10.8 | 11.6 | 12.4 |

| 2.5 | 0.8 | 1.4 | 1.8 | 1.8 | 1.8 | 1.8 | 6.2 | 11.2 | 11.7 | 12.6 | 13.5 |

| 4 | 1 | 1.4 | 1.8 | 1.8 | 1.8 | 1.8 | 7.1 | 12.9 | 13.6 | 14.7 | 15.9 |

| 6 | 1 | 1.4 | 1.8 | 1.8 | 1.8 | 1.8 | 7.6 | 13.9 | 14.7 | 15.9 | 17.3 |

| 10 | 1 | 1.4 | 1.8 | 1.8 | 1.8 | 1.8 | 8.7 | 16.2 | 17.1 | 18.6 | 20.3 |

| 16 | 1 | 1.4 | 1.8 | 1.8 | 1.8 | 1.8 | 9.8 | 18.4 | 19.5 | 21.3 | 23.3 |

| 25 | 1.2 | 1.4 | 1.8 | 1.8 | 1.8 | 1.8 | 11.2 | 21.2 | 22.5 | 24.7 | 27.1 |

| 35 | 1.2 | 1.4 | 1.8 | 1.8 | 1.8 | 1.9 | 12.4 | 23.6 | 21.4 | 27.6 | 30.5 |

| 50 | 1.4 | 1.4 | 1.8 | 1.8 | 1.9 | 2.1 | 14 | 23.4 | 27.2 | 31.5 | 35.2 |

| 70 | 1.4 | 1.4 | 1.9 | 2 | 2.1 | 2.2 | 15.6 | 26.8 | 28 | 31.6 | 37.9 |

| 95 | 1.6 | 1.5 | 2 | 2.1 | 2.2 | 2.4 | 17.9 | 27.2 | 31.4 | 36.6 | 43 |

| 120 | 1.6 | 1.5 | 2.1 | 2.2 | 2.4 | 2.5 | 19.3 | 29.8 | 34.3 | 39.2 | 46.9 |

| 150 | 1.8 | 1.6 | 2.2 | 2.3 | 2.8 | 2.7 | 21.4 | 32.6 | 37.9 | 43.1 | 52.4 |

| 185 | 2 | 1.7 | 2.4 | 2.5 | 2.7 | 2.9 | 23.7 | 38.6 | 42.3 | 48.2 | 60.7 |

| 240 | 2.2 | 1.8 | 2.6 | 2.7 | 2.9 | 3.1 | 26.5 | 43.8 | 49.7 | 55.7 | 65.8 |

| 300 | 2.4 | 1.9 | 2.7 | 2.9 | 3.1 | 3.3 | 29.3 | 48.8 | 52.8 | 62.3 | 71.4 |

FAQ

Q: Can we have our logo or company name to be printed on your products or the package?

A: The OEM & ODM order is warmly welcome and we have fully successful experience in OEM projects. What’s more, our R&D team will give you the professional suggestions.

Q: What’s the payment terms?

A: 30% T/T deposit, 70% T/T balance payment before shipment.

Q: How does your factory do regarding quality control?

A: We have a strict quality control system, and our professional experts will check the appearance and test functions of all our items before shipment.

Q: How can I get a sample to test your quality?

A: We can provide free samples for your test and checking, just need to bear the freight charge.

Contact us for more informations about our products, our professional team will serve you and customized according to your requirements.