Machining Of Aluminum Parts–More Than 10 Years Of Processing Experience

Aluminum materials has different grades which can be done different surface treatments to meet the production requirements Common aluminum grades and surface treatments are as follows

| Common Aluminum & Surface treatment | |

| Aluminum | LY12、2A12、A2017、AL2024、AL3003、AL5052、AL5083、AL6061、AL6063、AL6082、AL7075、YH52 |

| YH75、MIC-6,etc. | |

| Surface treatment | Anodize Clear、Anodize Black、Hardness Anodize Black/Clear、Aluminium alloy oxidizing |

| chromate plating、Electroless Nickel、Anodize Blue/Red,etc. | |

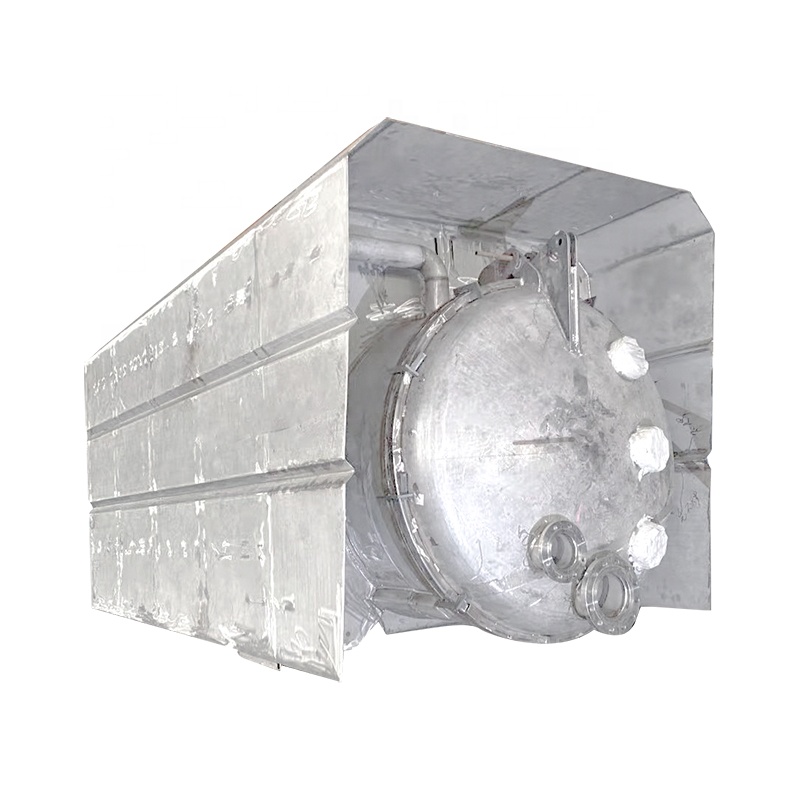

The aluminum processing services we can provide

● CNC Aluminum Turning、Aluminum Turning

● CNC Aluminum Milling、Aluminum Milling

● Aluminum turn-milling machining

Advantages of CNC machining utilizing aluminum alloy

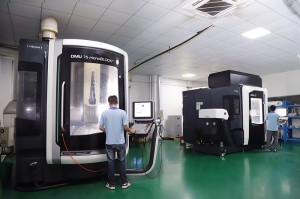

1、Aluminum parts have good machinability and do not require very high cutting tools. Different processing equipment can be used to design and manufacture a large number of complex parts according to pre-programmed procedures

2、In order to enhance the corrosion resistance of aluminum parts, different color surface treatments can be carried out, which enriches the diversity of products and better meets its multi-functional use;

3、The density of aluminum parts is small, the tool wear is small during processing, and the cutting is fast. Compared with steel parts, the processing cost is relatively low, and it is more stable, reliable and efficient in the part production process.

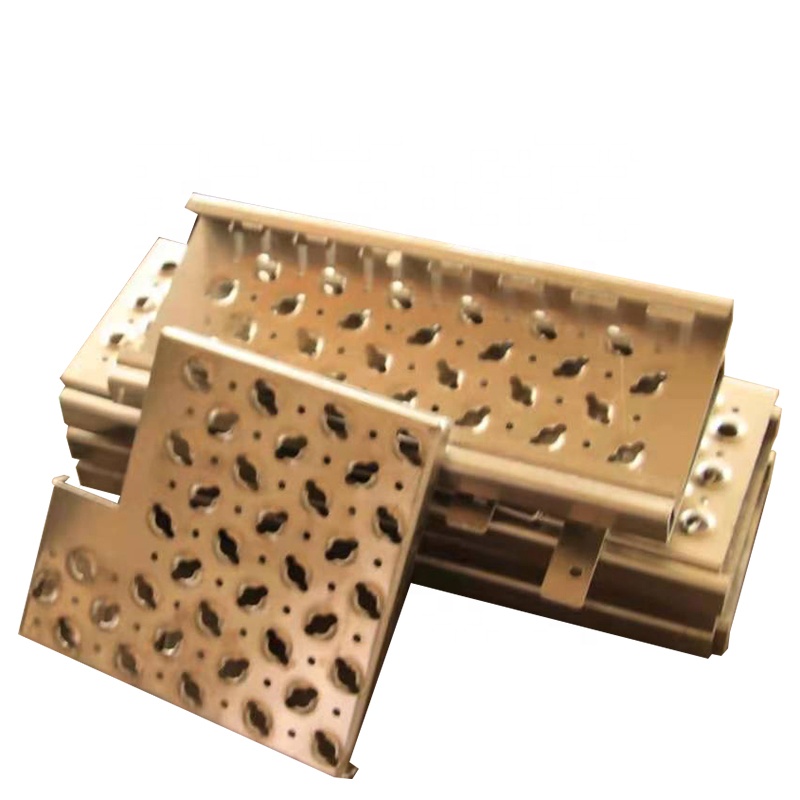

Other material processing

In addition to the processing of aluminum parts, we are also good at stainless steel processing, iron processing, copper parts, process plastics and other materials customized processing.