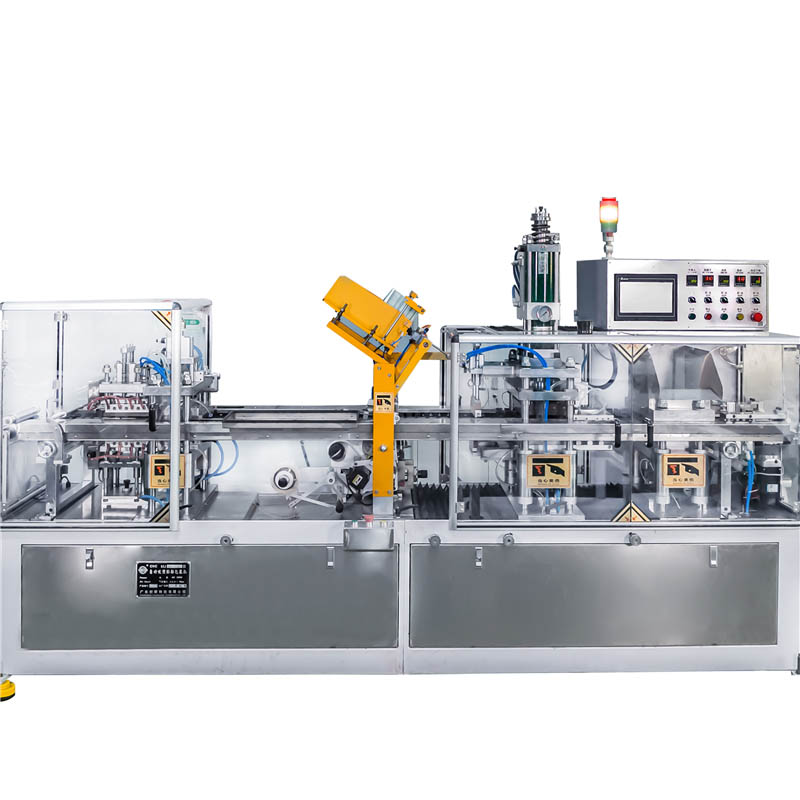

Mechanical Quantitative Stuffer JDG-1800

Introduction

This Mechanical Stuffer is the Gen. 2nd improvement, built with the Japan YASKAWA servo motor as the drive system, the man-machine interface from Taiwan, and the Japan Mitsubishi PLC. It features the advantages of low faults, simple construction and easy maintenance. Meanwhile a precise quantitative function is available with this Stuffer, with a quantitative deviation for minced meat of only ±2g, while the deviation for meat splice is little bit larger. By using it systematically with the dual clipper, you can manage your production activity in full automation.

Model

| Model | Quantitative Range(g) | Stuffing and Kinking Speed(Times/Min) | Quantitative Deviation (minced meat)(g) | Hopper Volume(L) | Power(kw) | Rated Voltage(v) | Weight(Kg) | Dimensions |

| JDG-1800 | 6-9999 | 10-70 | ±2 | 110 | 2.7 | 380V | 205 | 750*750*1700 |

Application

This machine has reasonable structure design and beautiful appearance. Simple operation and accurate quantification. The quantification can be arbitrarily adjusted between 50-15000g, and the error of normal cmous products is about ±3g. The control part adopts PLC and man-machine interface to make the action more accurate and less prone to failure. It can be connected with all kinds of automatic double-card machines produced by our factory to realize automatic production, improve the production efficiency of products, and ensure the quality of products. This machine adds vacuum pump on the basis of the original, so that the meat can better maintain the freshness. This machine is a minced meat and meat filling equipment produced by our factory. It is an ideal equipment for small and medium-sized meat processing enterprises to produce round ham.