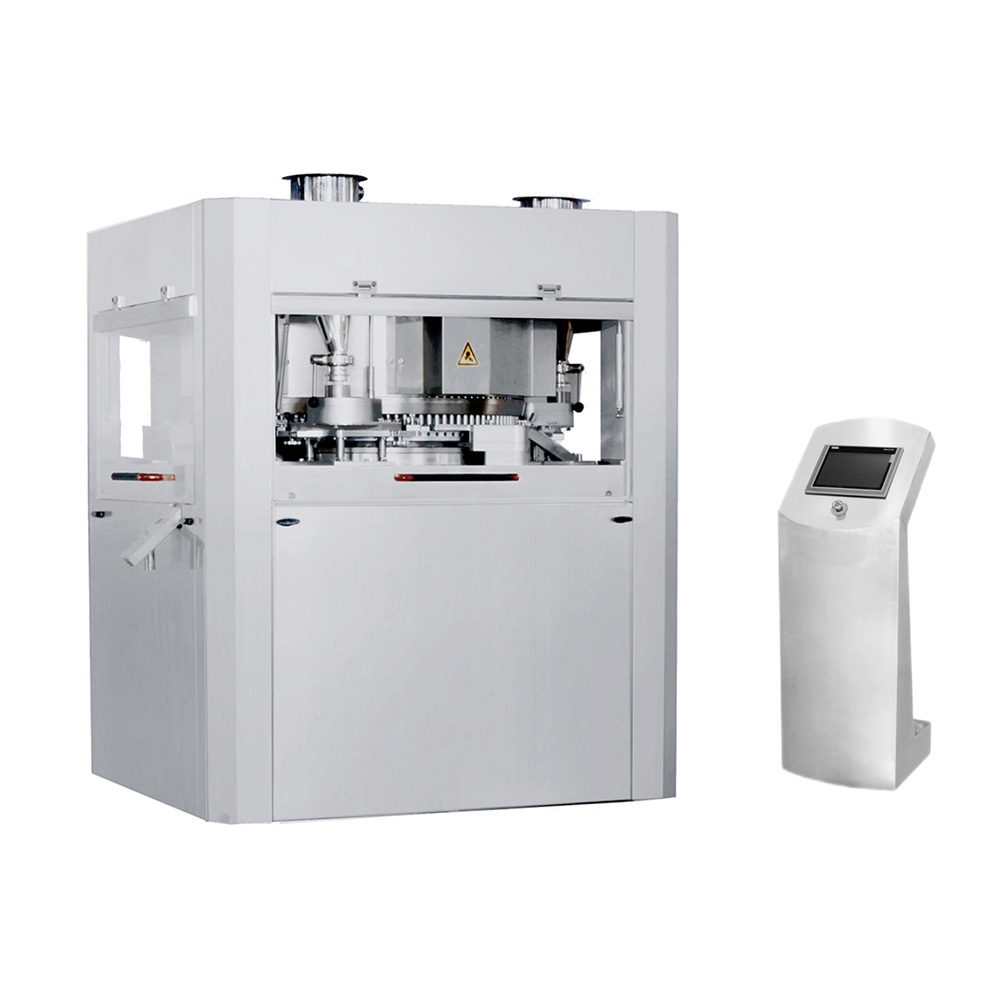

Metal extrusion/hot die forging hydraulic press

Key Features

Advanced Manufacturing Process: The Metal extrusion/hot die forging draulic press utilizes advanced extrusion and forging techniques, providing superior quality and efficiency compared to traditional manufacturing processes. This leads to enhanced product performance and durability.

Minimized Material Waste: With its non-cutting chip processing approach, the Metal extrusion/hot die forging draulic press significantly reduces material waste. This results in cost savings and contributes to environmental sustainability.

High Efficiency: The draulic press operates at high speeds and offers precise control over the extrusion and forging processes. This allows for increased production rates and efficient manufacturing operations.

Wide Range of Applications: The Metal extrusion/hot die forging draulic press is suitable for various industries. It can produce a diverse range of metal components used in automotive, machinery, light industry, aerospace, defense, and electrical equipment. This versatility makes it a valuable asset for manufacturers in different sectors.

Improved Component Strength and Precision: The extrusion and forging processes applied by the draulic press result in components with enhanced strength and precision. This ensures optimal performance, reliability, and longevity of the manufactured parts.

Applications

Automotive Industry: In the automotive sector, the Metal extrusion/hot die forging draulic press is extensively used for manufacturing critical components such as engine parts, transmission parts, chassis components, and steering system parts. The high-quality and precise manufacturing process of the draulic press ensures the production of reliable and durable automotive components.

Machinery Manufacturing: The draulic press is suitable for producing various metal components used in machinery manufacturing, including shafts, gears, bearings, and connectors. These components are essential for the proper functioning of machinery and equipment in different industries.

Aerospace and Defense: The Metal extrusion/hot die forging draulic press finds application in the aerospace and defense sectors. It is used to manufacture critical components for aircraft, rockets, missiles, and defense machinery. The high strength and precision of the produced components contribute to the overall performance and safety of aerospace and defense systems.

Light Industry and Electrical Equipment: The draulic press is also widely adopted in the manufacturing of metal components used in light industry products and electrical equipment. This includes items such as household appliances, power tools, and electrical connectors, where high precision and reliability are crucial.

In conclusion, the Metal extrusion/hot die forging draulic press offers an advanced manufacturing solution for the production of high-quality metal components. Its advantages include advanced manufacturing processes, reduced material waste, high efficiency, and a wide range of applications across various industries. From automotive and machinery manufacturing to aerospace, defense, and electrical equipment sectors, this draulic press enhances component strength and precision, ultimately leading to enhanced