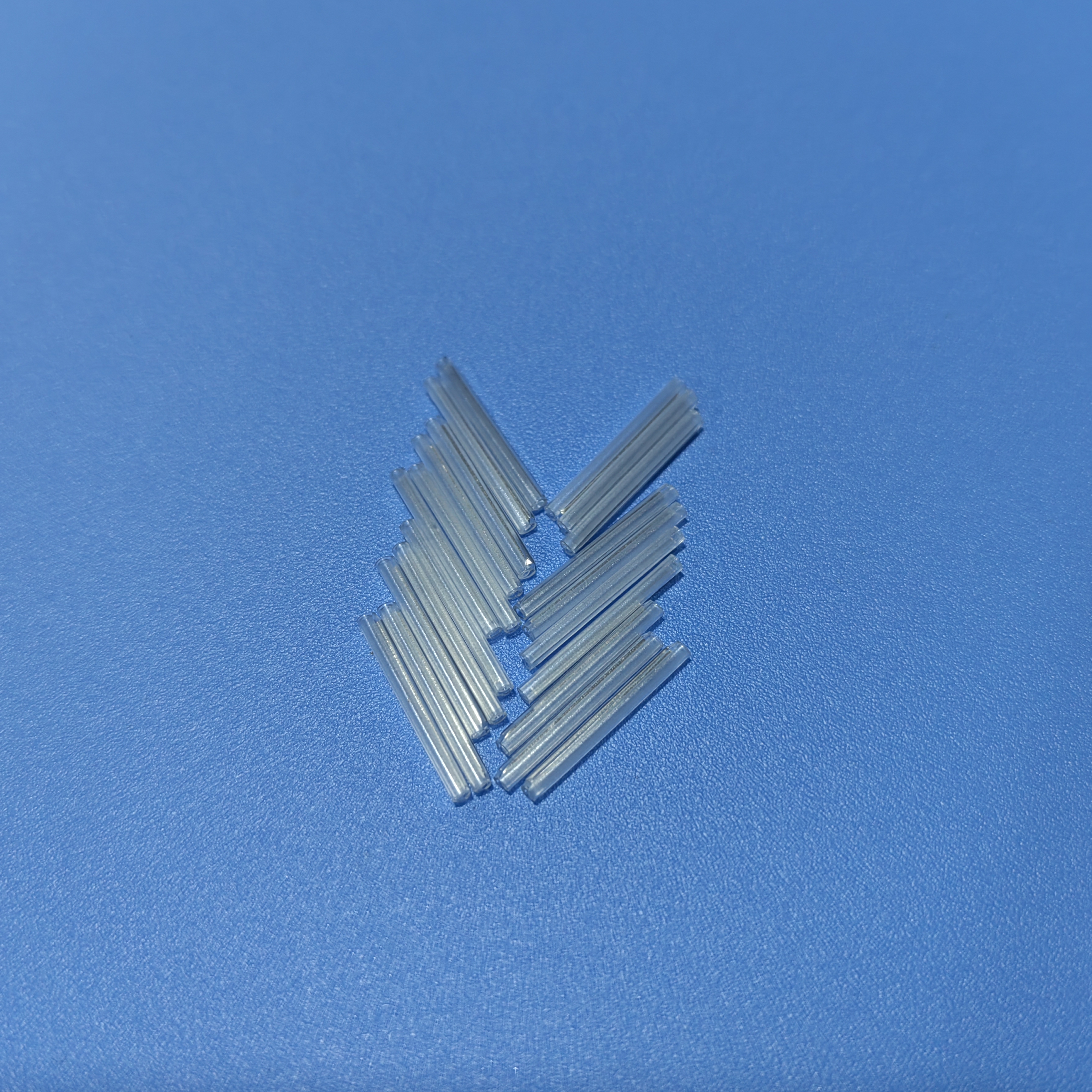

Micro Heat Shrink Protection Sleeve in 0.5 Diameter 304SS

Detail Information

| Name | Micro Heat Shrink Protection Sleeve in 0.5 Diameter 304SS |

| Spec. | 0.5*35*304 |

| Use | FTTx&FTTH |

| Material | EVA |

| Use For | Fiber Distribution Box |

| Series | Micro |

| Length | 35mm |

| Color | Clear |

Features

1.Easily use and avoid any damages to the optical fiber during installation

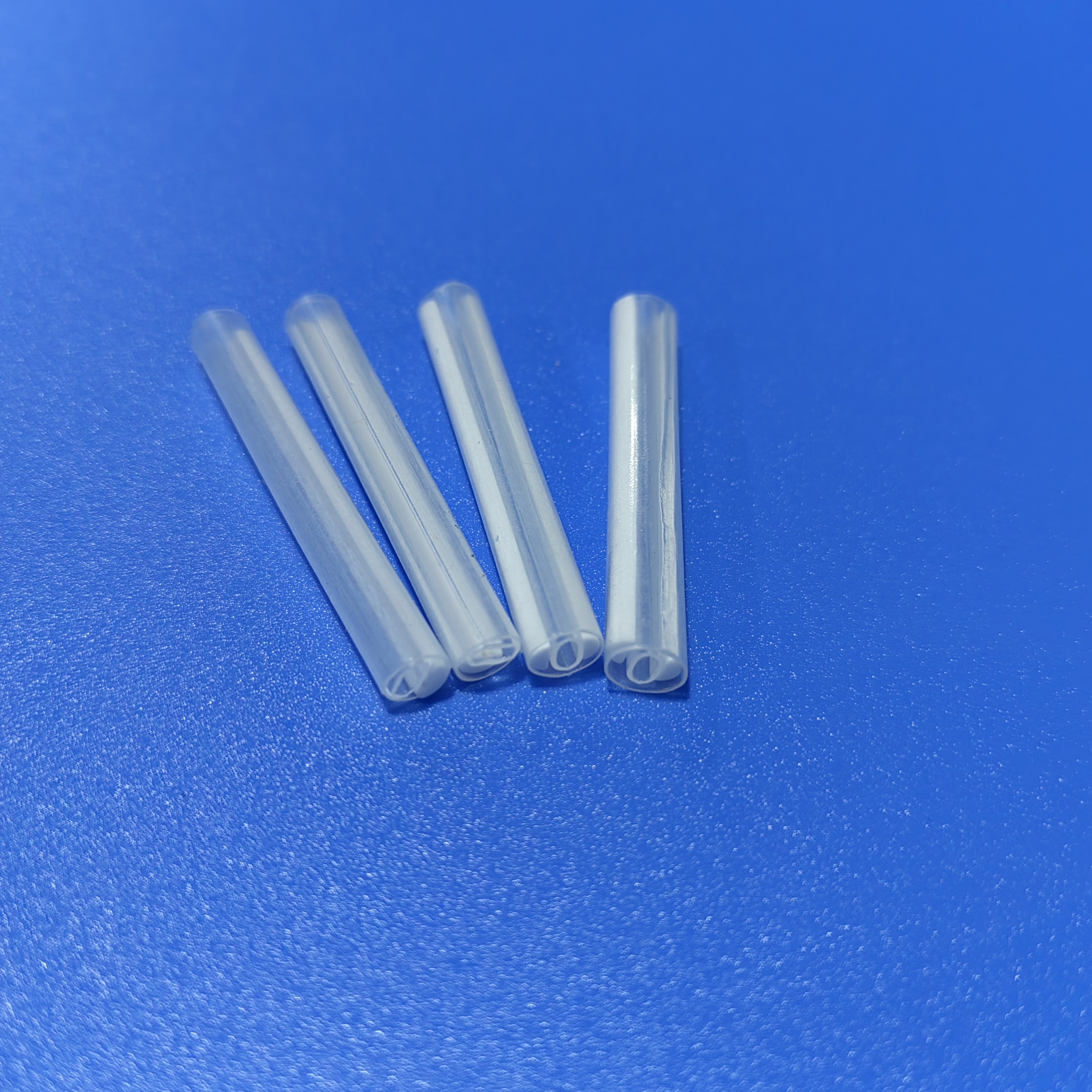

2.Clear sleeve make it easy to detect splice before shrinkage

3.Airproof configuration keeping the splice point’s good resistance of humidity and temperature

4.Strength member is made from “Full hard” stainless steel of 304 grade and is ground at the edges before polishing to make it completely burr free to avoid rupturing during shrinking. 304 grade gives better corrosion resistance, even in coastal environment. Resistant to heat shocks, no cracking dripping or flowing.

Description

1.Designed to restore complete environmental and mechanical integrity of coating or buffer of optical fiber after splicing.

2.Sleeves are manufactured using state of the art machines and controlled manufacturing environment in an ISO 9001 certified manufacturing facility.

3.Outer tube conforms to MIL-I 23053/5 class 2 standards.

4.Hot melt adhesive tube made from polyolefin Etl Vinyl Acetate copolymer bonds both to the fiber and heat shrinkable outer tube to effectively encapsulate fusion splice.

5.Strength member is made from “Full hard” stainless steel of 304 grade and is ground at the edges before polishing to make it completely burr free to avoid rupturing during shrinking.

6.304 grade gives better corrosion resistance, even in coastal environment. Resistant to heat shocks, no cracking dripping or flowing.

7.Long term proven performance, exceeds industry standards with satisfied customer.

Application

When protecting optical fibers with optical fiber heat shrinkable tubes, attention should be paid to:

1. Avoid residual air bubbles in the protection tube to ensure the temperature characteristics and long-term reliability of the optical fiber connector;

2.The optical fiber should apply a uniform tension to ensure that the optical fiber is in a straight state in the protection tube;

3.Avoid optical fiber twisting and prevent increased loss caused by micro-bending;

4.The applied tension should not be large to avoid damage caused by increased fiber cracks;

5.Wait for the heat shrinkable tube to completely shrink, cool and shape before releasing the tension, so as to avoid micro bends or macro bends caused by uneven local heating of the optical fiber.