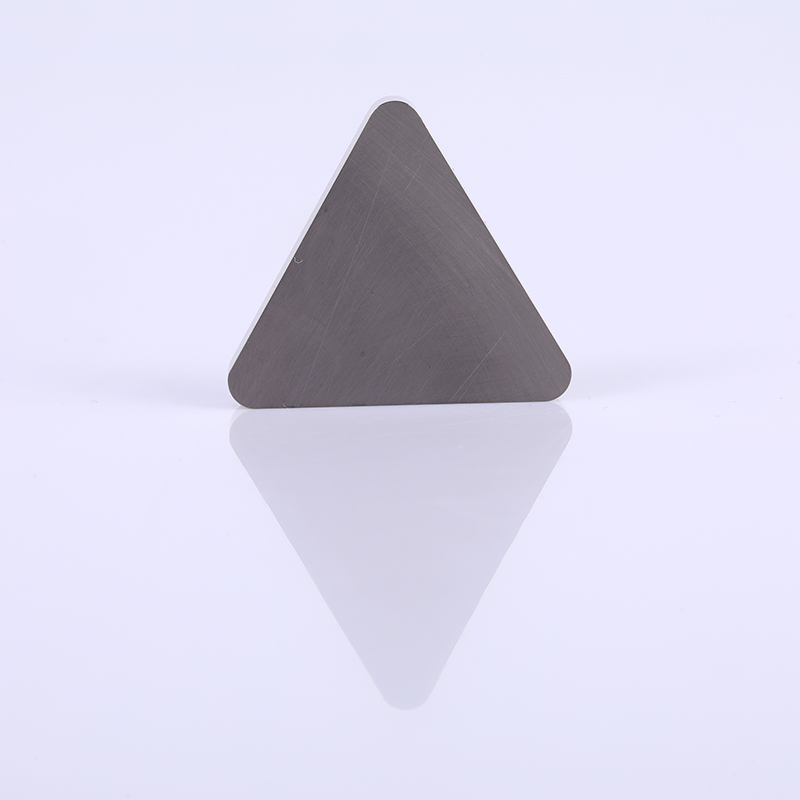

Molding Cermet Bearing Inserts TNMN330420 MC3015 High Quality

Product Detail

Metcera always provides our customers the cermet products with good quality, competitive price, fast delivery time and reliable after services.

Why Choose Metcera

The sole one in China focus on cermet products only and cermet grinding solution,

Manufacturer of integrating row materials, R &D, design, manufacturing.

Over 30 years focus on cermet materials research and development.

The best R &D team of cermet in China.

The sole one in China own all the technologies of every process.

Equipped with the best machines, like press machine from Osterwalder, Grinder from Agathon.

ODM service is provided.

Features

-High chemical stability ensures no build-up edge

-Excellent surface quality in continuous finishing machining

-Excellent resistance against chipping, fracture and thermal crack

- High red hardness and wear resistance in dry cutting

- Long tool life for bearing steel applications

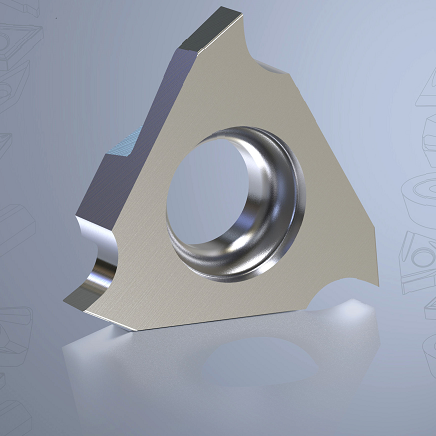

Applications

Ti(CN) based cermet is a composite material that combines ceramic and metallic materials. Cermet grades provide long tool life and excellent surface finish, combining toughness with superior wear resistance. Our PVD coated cermet offers less deterioration and more bending strength. This enables you to choose the perfect tool fitting your demand for high performance cutting.

Parameters

| Insert Type | TNMN330420 |

| Grade | MC3015 |

| Material | TiCN Cermet |

| Hardness | HRA93.2 |

| Density(g/cm³) | 7.1 |

| Transverse Rupture Strength (MPa) | 1800 |

| Workpiece | Carbon steel, alloy steel, gray cast iron |

| Machining method | Finishing and semi-finishing |

| Application | Bearing |

FAQ

Q: Do you have your own R&D team?

A:Yes, we have a R&D team of over 15 engineers.

Q:When is the leading time?

A:Normally 10 days after receiving your payment,but it can be negotiated based on order qty and production schedule.

Q:What kind of payment terms you accept?

A:T/T,West Union,Paypal,Credit Card and other main terms.

Q:Do you provide customized solutions

A:Yes, we can customize both inserts and carbide solid tools based customer’s requirement.

Q:What kind of machines are you using?

A:Osterwalder presser,Agathon Grinder,Nachi manipulator,etc.

Q:What’s the main application of your products?

A: Our products are used for metal cutting applications such as automobile, medical, die-mold, petroleum, 3C and many other industries.