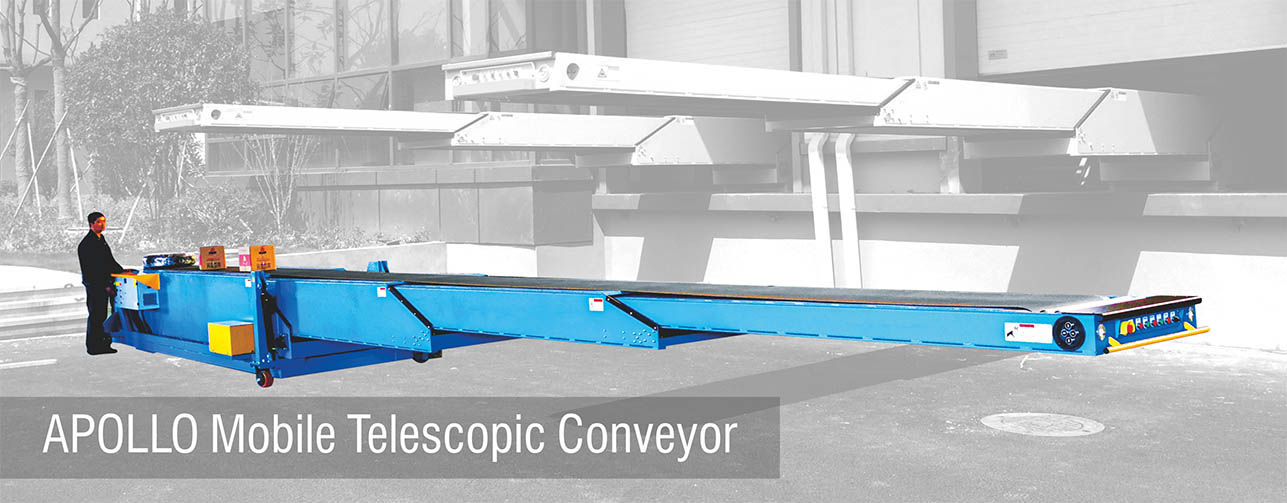

Movable Telescopic Belt Conveyor With Motorized System For Easy Movement

Industry Applications

Movable Telescopic Conveyor is suitable for unfixed loading/unloading sites. Machine can move randomly, conveniently change position according to the goods or the position of the trucks / containers. Widely used in E-commerce, Third party logistics, Food, Beverages, Pharmaceuticals, Clothes, Tires, Furniteure and FMCG etc.

●One operator can move machine easily

● Improve the flexibility of operation within bigger space

● One conveyor can serve for multiple loading doors

● Shorten the time of loading and unloading, reduce labor intensity

●The Maximum loading amount up to 2250 per hour if based on standard loading speed of 30 m/min for carton (800x600mm)

● Labor can reduce more than 2/3 based on original loading way

● Minimum the lowest accident in the process of loading, even zero incidence

● Promote the enterprise image, conform to the requirements of the modern enterprise

Telescopic Belt Conveyor gives you precise control at the shipping dock by extending length into the end of the truck trailer. A full set of operation buttons improve the loading and unloading efficiency of goods in truck and bring convenient operation. When add caster wheels or install the telescopic belt conveyor at rail or equip with motorized movement system, it can improve the flexibility of operation with bigger space, solve the easy and efficient loading or unloading goods. You press a button only then the conveyor can travel anywhere you want.

Telescopic belt conveyor can freely extend on the length direction according to the loading requirements through adjusting buttons. Operation height conforms to ergonomic design, easy to handle goods, reduce the labor intensity of workers.

Goods type: carton, bag, parcel, luggage, tire, plastic box, barrel etc.

Loading capacity: 50kg/m (standard)

Move type: manual movement, rail traverse movement, motorized movement.

| Model | Sections | Total length C(mm) | Retracted length A(mm) | Extension length B(mm) | Height(mm) | Belt width(mm) | Mobile way |

| M3-6+8 | 3 | 14000 | 6000 | 8000 | 900 | 600/800/1000 | Manual / Motorized |

| M3-7+9.5 | 16500 | 7000 | 9500 | 900 | 600/800/1000 | Manual / Motorized | |

| M4-5+10 | 4 | 15000 | 5000 | 10000 | 900/1050 | 600/800/1000 | Motorized |

| M4-6+12 | 18000 | 6000 | 12000 | 900/1050 | 600/800/1000 | Motorized | |

| M4-7+14 | 21000 | 7000 | 14000 | 1100 | 600/800/1000 | Rail | |

| M4-8+16 | 24000 | 8000 | 16000 | 1100 | 600/800/1000 | Rail |

Frequently Asked Questions:

Equip with tower light, easy to see machine status; 4 directions buttons, easy operation

Simens PLC control system gets convenient remote maintenance and after-sales service

Schneider VFD to adjsut speed, quality stable

Control handle to operate the movement of conveyor

DC type travel motor for easy movement

Equip with battery as the power for motorized movement

Easy entry for maintenance from back cover

Anti-clamping roller, avoid the risk of clamping hands for operators

Equip with sensors to prevent goods fall (optional)

Cut steel plate by laser

Bending

Welding

Polishing

Wiring

Assembly

Powder coating

Forming frame

Finished product

Telescopic test

Movement test

Deliver at user’s site

Our innovation is at your service

Consumer behavior has changed, supply chains have not. Let’s talk today to find perfect design and make your loading or unloading more easy, more safe, more efficiency.