Muscovite Mica High Temperature Resistance For Cosmetic Paint Coating

Unique Properties

● Layered structure

● Chemical resistance

● Low thermal conductivity

● Heat stability

● Low coefficient of friction

● Vibration damping (acoustics)

● Flexible

Chemical Composition

|

Element |

SiO₂ |

Al₂O₃ |

K₂O |

Na₂O |

MgO |

CaO |

TiO₂ |

Fe₂O₃ |

S+P |

|

Content (%) |

38.0-50.0 |

13.3-32.0 |

2.5-9.8 |

0.6-0.7 |

0.3-5.4 |

0.4-0.6 |

0.3-0.9 |

1.5-5.8 |

0.02 |

Physical Property

|

Thermal Endurance (℃) |

Mohs Hardness |

Density (g/cm³) |

Dielectric Strength (KV/mm) |

Tensile Strength (MPa) |

Surface Resistivity (Ω) |

Melting Point (℃) |

|

650 |

2.5-3 |

2.8-2.9 |

115-140 |

110-145 |

1×1011-12 |

1200 |

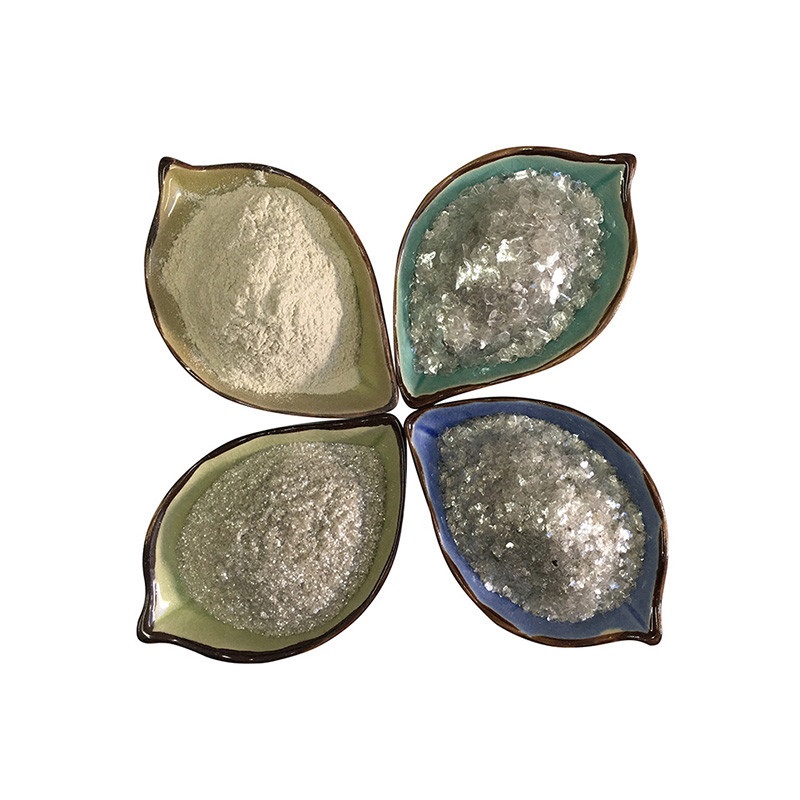

Processing Technology

There are two manufacturing processes of mica powder: dry grinding and wet grinding. We have our own factories to produce these two products.

Dry ground mica powder is produced by physical grinding without changing any natural property of mica. We adopt total enclosed filling system to guarantee quality during the whole production process. In the screening process,we also employs proprietary equipment and technology to ensure uniform particle distribution and stable quality. As to its superior performance, dry ground Muscovite has been extensively used in production of various products, including fiber cement construction panels / wallboards, plastics, rubber, paint, coating, welding electrodes, oil drilling and brake pads.

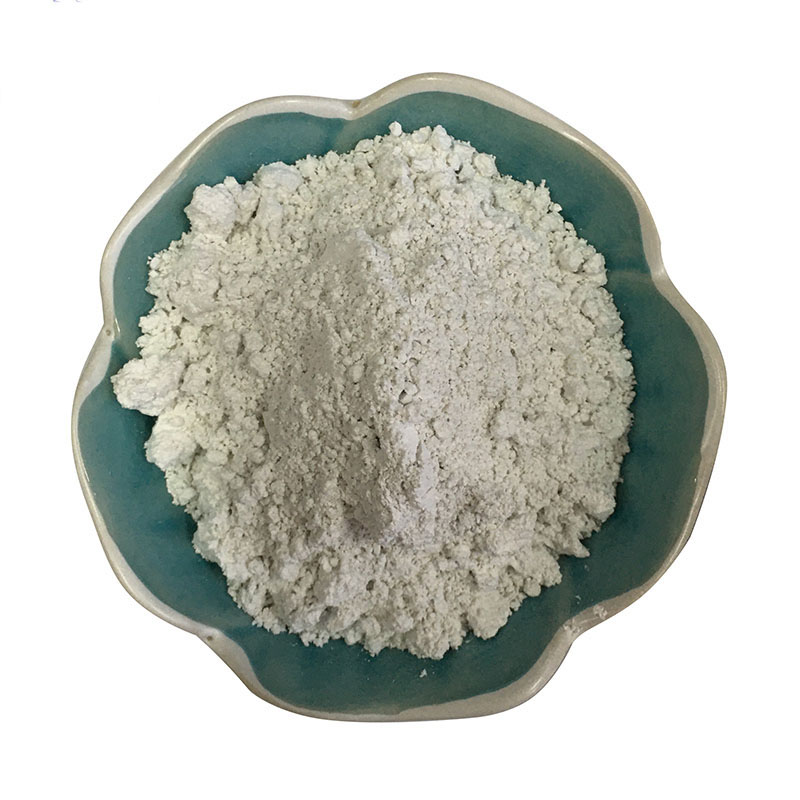

● Dry ground process

Wet ground mica powder is produced from natural mica flakes through a series of processes, including cleaning, washing, purification, wet grinding, drying, screening and grading. The unique production process retains the sheet structure of mica , therefore wet ground mica is featured by large radius-thickness ratio, low sand and iron content, high purity, whiteness and glossiness. The unique property of wet ground mica makes it widely used in industries such as paint, coating production, rubber, plastics and ceramics. It is especially effective to improve product’s electrical strength, rigidity, heat resistance and to reduce molding shrinkage and cost.

● Wet ground process

Certificate

Our factories have achieved ISO Certificate, 23 technologies have obtained national patents.

Application

Muscovite Mica is widely used in Polymers/Plastics Rubber, Paints, Coatings, Fiber cement construction panels/ Wallboards, Ceramics, Sound-damping, Cosmetics, Electrodes, Brake pads, Oil drilling.

Plastic

Rubber

Paints

Coatings

Cosmetics

Wallboards

Ceramics

Oil drilling

Specification

20 mesh, 40 mesh, 60 mesh, 100 mesh, 200 mesh, 325 mesh, 600 mesh, 1000 mesh, 1250 mesh, 3000 mesh.

6-10 mesh

10-20 mesh

1250 mesh

100 mesh

2500 mesh

Packaging

Commonly package is 25kg PP bag/paper bag, 500kg~1000kg jumbo bag. Also could customize as required.