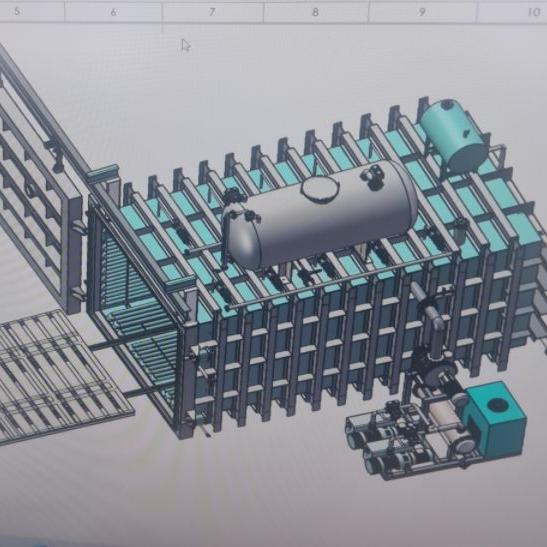

Natural Gypsum Powder Production Plant

Production Process

Multiple processes are taken in production of the plant. First, gypsum ores are being crushed, conveyed and stored into raw material bin, and then the crushed gypsum ores get grinded into powder with fineness required by the raymond mill, and the gypsum powder is then conveyed into calcining section via metering feeding device to get calcined, and the calcined gypsum gets modified by grinder and cooled by cooling device. Finally, the finished gypsum is conveyed for storage.

The plant consists of these sections/units

Material Consumption Parameters

|

Tons/Year |

Tons/Hour |

Ore Consumption (Tons/Year) |

|

20000 |

2.78 |

24000 |

|

30000 |

4.12 |

36000 |

|

40000 |

5.56 |

48000 |

|

60000 |

8.24 |

72000 |

|

80000 |

11.11 |

96000 |

|

100000 |

13.88 |

120000 |

|

150000 |

20.83 |

180000 |

|

200000 |

27.78 |

240000 |

|

300000 |

41.66 |

360000 |

Advantage

1. The feeder of mill adopts frequency conversion belt conveyor, its running speed is related to the mill electric current, and the automatic feeding function can be realized through PLC integrated control. Compared with the traditional electromagnetic vibration feeder, the feeder has the characteristics of long service life and stable feeding. The permanent magnet iron remover is set on the upper part of the belt conveyor, which can effectively prevent the iron products from entering the mill and causing damage to the mill;

2.The powder collected by the bag filter of the mill is directly transported to the system by a special screw conveyor to reduce the intensity of workers;

3.A gypsum powder buffer bin is set between grinding and calcination, which has two functions. First, it has the function of stabilizing the material. The gypsum powder can be temporarily stored here before entering the fluidized bed furnace. When the front-end discharge is unstable, the stable feeding of the fluidized bed furnace will not be affected. Secondly, it has the storage function. The calcination stability of gypsum powder depends on the stable supply of materials and stable heat supply, and the interruption in the production process should be avoided as far as possible, because there are some quality defects in the gypsum powder before startup and after shutdown. If there is no such silo, the equipment at the front end will be shut down when there is a problem, and the calcination quality of gypsum powder will not be stable when the supply at the front end is unstable;

4.The feeding conveyor in front of the fluidized bed furnace adopts metering conveying equipment. Changing the traditional frequency conversion conveying mode,the functions of accurate feeding and clear production capacity can be realized by using the metering conveying;

5.The hot air fluidized bed furnace is used in the calcination equipment,and we have made some improvements of this basis:

a. Increase the internal space of fluidized bed furnace, prolong the residence time of gypsum powder in the interior, make the calcination more uniform;

b. The installation process of heat exchange tube independently developed by our company can effectively avoid the cracking of fluidized bed furnace shell caused by thermal expansion and cold contraction;

c. The dust chamber on the top of the fluidized bed furnace is increased, and the pre dust collection device is designed at the outlet to reduce the discharge of gypsum powder and increase the production efficiency of the fluidized bed furnace;

d. A waste heat recovery heat exchanger is added between the bottom roots blower and the connecting pipe of the fluidized bed furnace. The normal temperature air is heated by the heat exchanger first, and then added into the fluidized bed furnace, so as to increase the thermal efficiency of the fluidized bed furnace;

e. Special powder conveying equipment is set up. When the inside of fluidized bed furnace and cooler needs to be cleaned, the powder is first transported to the waste bin through the conveying equipment to achieve a clean working environment.

6. The special cooler for gypsum powder is set, and the gypsum powder cooler is set at the back end of the fluidized bed furnace, which can effectively reduce the temperature of gypsum powder before entering the silo, avoid the secondary calcination of gypsum powder in the silo, and effectively ensure the quality of gypsum powder;

7. The finished product storage section has expansibility. Customers can add gypsum powder waste bin in this section. When unqualified powder appears during startup and shutdown, the unqualified powder can be directly transported to the waste bin through PLC centralized control. The gypsum powder in the waste bin can be transported to the system in a small amount in the normal production process of gypsum board;

8. Core equipment We use international famous manufacturers as partners, PLC uses Siemens brand, and the burner uses German Weso brand;

9. Our company has first-class design team, first-class processing team, first-class installation and debugging team, first-class equipment. It is the necessary guarantee for customers to get qualified and stable products.

Features of Our Natural Gypsum Plant

1. A material supplement stabilizing system is deployed to achieve stable supplement of the fluidized bed combustion boiler, and to stabilize material supplement and heating. Material supplement stabilizing system consists of material supplement stabilizing bin and conveying device (metering screw or belt weigher).

2. Calcining system applies hot air boiling furnace calcining process to perform even calcination on gypsum material.

3. Cooling device added to cool down calcined gypsum before it enters silo, to prevent gypsum from deterioration caused by over temperature.

4. Silo turn-over system: materials at different time periods feature different quality, therefore products made from them feature different quality. The silo turn-over system can evenly mix new and old materials, make the products share the same quality. Besides, the system prevents overheating deterioration caused by heat generated by powder accumulation.

5. The dust removal system applies a bag type dust collector, to ensure dust generated during pre-drying, conveying, grinding, calcination and aging processes get cleaned before discharging outside, to meet working environmental requirements.

6. Distributed control system is applied, to do centralized control on distributed devices.

Gypsum Products Parameters

1.Fineness: ≥100 mesh;

2.Flexural Strength (having a direct relation to raw material): ≥1.8Mpa; The Strength of Antipressure: ≥3.0Mpa;

3.Main Contents: Hemidrate: ≥80% (Adjustable);Gypsum <5% (Adjustable);Soluble Androus <5%(Adjustable).

4. The Initial Setting Time: 3-8min (Adjustable); the Final Setting Time: 6~15min (Adjustable)

5.Consistency: 65%~75% (Adjustable)