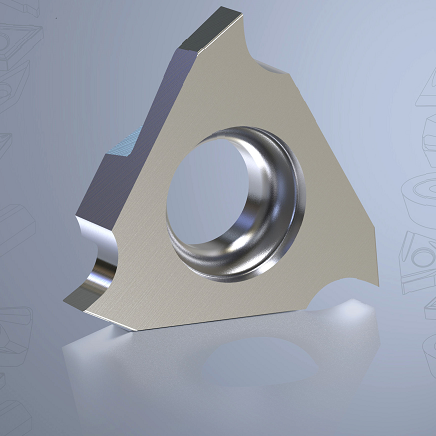

Negative Cermet Inserts WNMG060404-5FG Turning Inserts Milling Inserts MC2010

Product Detail

The Chipbreaker 5FG for finishing minimizes machining load at low depths of cut, has excellent chip control capability due to the wide, stable supporting area, and provides excellent chip evacuation in continuous and high speed machining of various workpieces. It also provides superior tool life due to improved surface finishes and lower cutting resistance.

Cermet grades are used in smearing applications where built-up edge is a problem. Their self-sharpening wear pattern keeps cutting forces low even after long periods in cut. In finishing operations, this enables a long tool life and close tolerances, and results in shiny surfaces.

The cermet may crack after electrical discharge machining (EDM), light grinding is needed before used.

Both dry cutting and sufficient cooling wet cutting are feasible. Avoid insufficient cooling and thermal shock in cutting.

Features

-High red hardness and high cutting speed in dry cutting( environmental friendly)

-High Oxidation resistance

-Both dry cutting and sufficient cooling wet cutting are feasible

-High chemical stability ensures no build-up edge

- Improved surface roughness in finishing machining

Applications

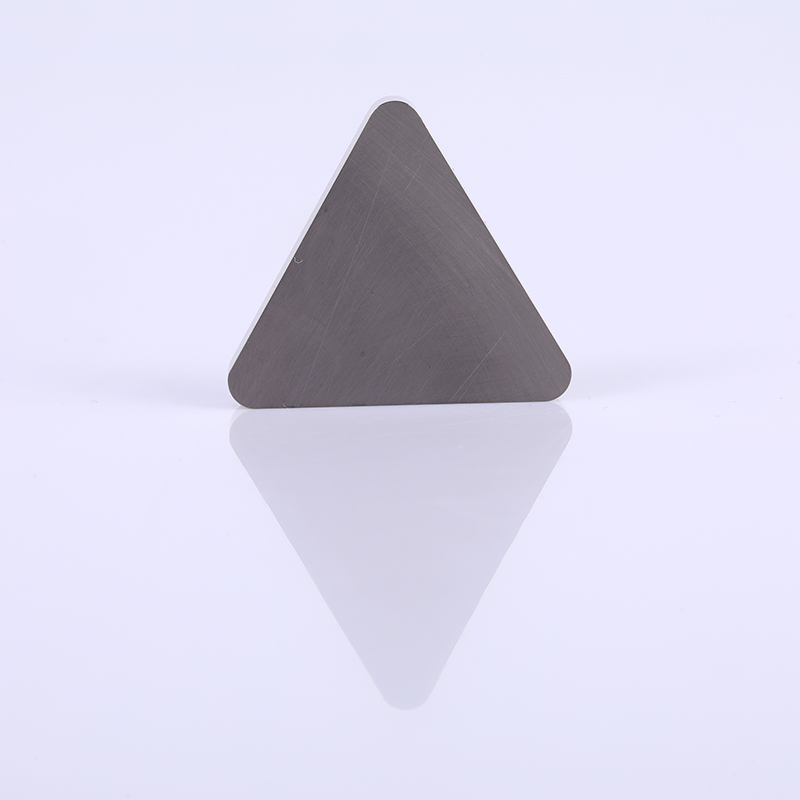

Ti(CN) based cermet is a composite material that combines ceramic and metallic materials. Cermet grades provide long tool life and excellent surface finish, combining toughness with superior wear resistance. Our PVD coated cermet offers less deterioration and more bending strength. This enables you to choose the perfect tool fitting your demand for high performance cutting.

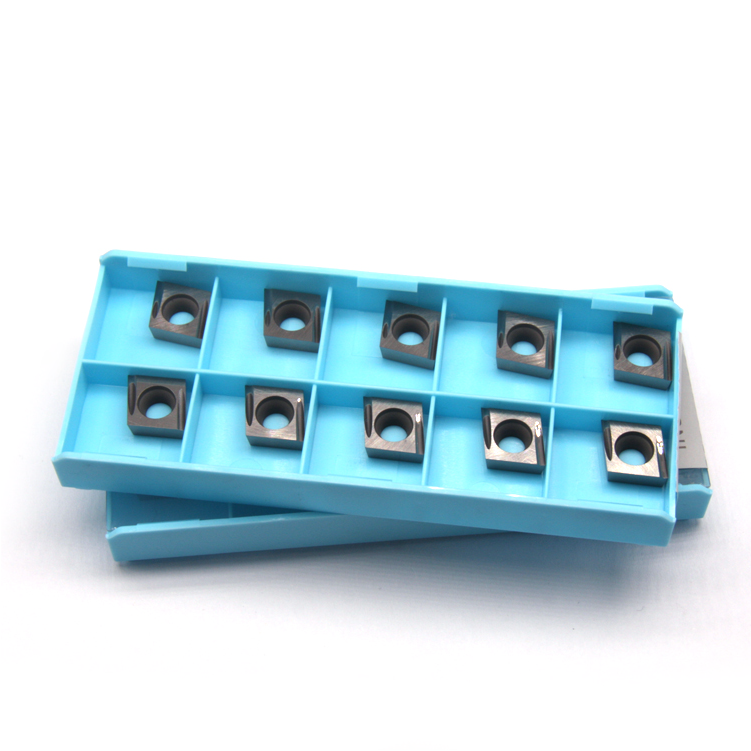

Parameters

| Insert Type | WNMG060404-5FG |

| Grade | MC2010 |

| Material | TiCN Cermet |

| Hardness | HRA92.5 |

| Density(g/cm³) | 6.75 |

| Transverse Rupture Strength (MPa) | 2300 |

| Workpiece | Carbon steel, alloy steel, gray cast iron |

| Machining method | Finishing |

| Application | Turning & Milling |

FAQ

Q:Are you trading company or manufacturer?

A:We are manufacturer.

Q:What’s your manufacturing capability?

A:Normally 10 days after receiving your payment,but it can be negotiated based on order qty and production schedule.

Q:What kind of payment terms you accept?

A:Metcera can manufacture up to 2-3 million inserts per month.

Q:How can you guarantee the production quality?

A:Our company is based on ISO9001,we have more than 30 years experience of QC team and strictly quality control system.However,90 days of free change is provided.

Q:What kind of machines are you using?

A:Osterwalder presser,Agathon Grinder,Nachi manipulator,etc.

Q:What about the shipment way?

A: We can arrange shipment via DHL, FEDEX, TNT, UPS upon customer’s request.