New Era High Efficiency Mask Machine with

New Era High Efficiency Mask Machine with,

high efficiency, new,

Main Feature

● Can put 3 ~ 4 layers of fabric into the equipment at the same time.

● Using ultrasonic technology, the surface layer, filter layer and bottom layer are automatically bonded. Then automatically press the crease of the outlet cover, trim, shape and cut.

● Through the conveyor system, it is automatically assigned to the left and right 2 sides.

● At the same time, through the photoelectric detection, the ultrasonic cutting and spot welding of the elastic straps are firmly fixed in the mask.

● With full-automatic output function, it realizes full-line automatic operation from feeding to finished products, with an efficiency of up to 100,000pcs/day (120pcs/min), which is helpful for the transformation and upgrading of intelligent production of masks.

● Automatically fold mask ear straps, which can be packed into bags without manual labor folding straps.

● Equipment production pass rate: 99.8-99.9%.

Specification

| Equipment size | 6800mm (L) × 3600mm (W) × 1900mm (H) |

| Equipment weight | ≤1500kg, ground load> 300KG / M²; |

| Working power supply | equipment 220VAC ± 5%, 50hz, rated power about 6.5-8.5kW, actual power 5.5kw. |

| Compressed air | 0.5 ~ 0.7MPa, the flow rate is about 300L / min; |

| Use environment | temperature 10 ~ 35 ℃, humidity 5-35% HR, no flammable, corrosive gas, no dust (cleanness is not less than 100,000) |

Detail Information

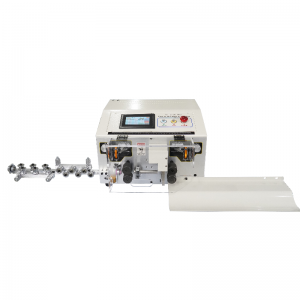

Fabric Holder

Ultrasonic & Cutter

1 for 2

Ultrasonic Welding

Automatically Fold

Final Packing Directly

Mask machine is a multilayer non-woven fabric through hot pressing, folding molding, ultrasonic welding, waste removal, ear band nose bridge welding and other processes to produce a variety of masks with certain filtering performance, mask production equipment is not a single machine, it needs the cooperation of several machines to complete a variety of different processes.