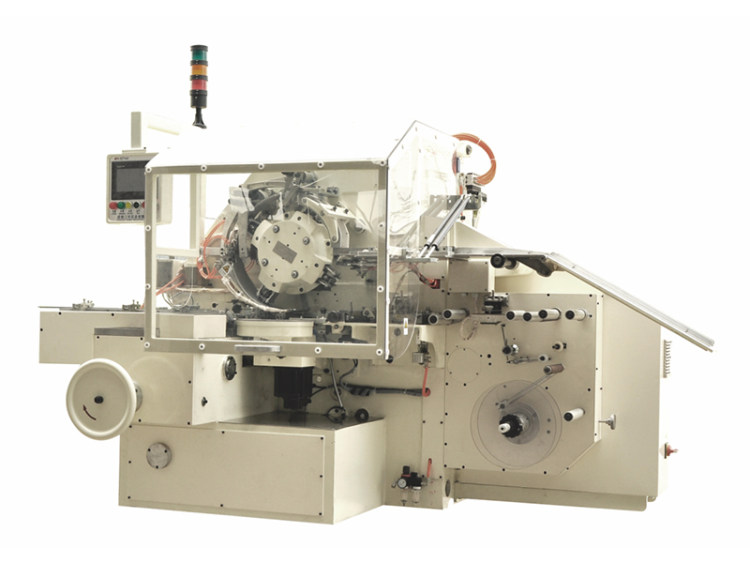

New Innovational Generation High Speed Cartoning Machine

Product Detail

◐ Box Cartoning Machine adopts automatic feeding, unpacking, feeding, sealing and output. And other packaging forms, the structure is compact and reasonable, and the operation and adjustment are simple

◐ Cartoning Machinery can be linked with aluminum-plastic packaging machine, pillow packaging machine, three-dimensional packaging machine, bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument, other production lines and other equipment to achieve linked production

◐ Cartoning Machinery with Mitsubishi or Siemens PLC control system easy to use touch screen control panel with cGMP design and standard

◐ High-Speed Cartoning Machine has High speed cartoner has .IPC control, high-precision, multi-performance, multi-axis motion control technology, achieving stable and reliable operation 3. IPC control, high-precision, multi-performance, multi-axis motion control technology, achieving stable and reliable operation

◐ High Speed Cartoning Machine has servo-drive system, realizing automatic product feeding, box erecting, box loading, glue spraying and sealing

◐ The photoelectric eye of Box Cartoning Machine automatic detection and tracking system is adopted, high speed cartoner has the empty package cannot be placed in the box, high speed cartoner saves the packaging materials to the greatest extent;

◐ Box Cartoning Machine with packaging range is large, the adjustment is convenient, and the quick conversion between various specifications and sizes can be realized

◐ Cartoning Machinery Can be used with aluminum-plastic packaging machine, pillow packaging machine, three-dimensional packaging machine, bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument, unpacking machine, packing machine, sealing machine, etc. Other production line equipment realizes linkage production

◐ High Speed Cartoning Machine Adopt PLC and man-machine interface to automatically control the operating system, stepless frequency conversion speed regulation, High-Speed Cartoning Machine has high degree of automation, easy operation and easy to understand

◐ Cartoning Machinery has functions such as fault display, alarm and finished product counting, which is convenient for maintenance and troubleshooting

◐ High Speed Cartoning Machine with Various automatic feeders and conveying mechanisms can be designed according to customer requirements

◐ High Speed Cartoning Machine Can be used with aluminum plastic packaging machine, pillow packaging machine, filling machine, soap making machine, inkjet printer (or supervision code system), labeling machine, online weighing instrument, three-dimensional packaging machine, heat shrink packaging machine, Belt strapping machine, other production lines, etc. to achieve docking linkage production

Technical parameter

NO.

ITEM

DATA

1

speed/capacity

100-120 carton/minute

2

machine dimension

3300×1550×1560

3

carton dimension range

minimum 45×20×14mm

maximum 250×150×120mm

4

carton material request

white cardboard 250-350g/m2

gray cardboard 300-400g/ m2

5

compressed air pressure/ air consumption

≥0.6Mpa/≤0.3m3 minute

6

main powder

1.5KW

7

main motor power

1.5KW

8

machine weight

(approx.) 1000Kg

Application field

High speed cartoner is suitable for medicine aluminum-plastic plates, round bottles, heterosexual bottles, food, school supplies, health products, toys, cosmetics, auto parts, toothpaste, paper towels, office supplies, hardware, household paper, poker, etc. and similar items It can automatically complete the folding of the manual, the opening of the carton, the boxing of the items, the printing of the batch number, and the sealing of the box.

Smart has many professional designers, who can design Cartoning Machinery according to the actual needs of customers

Please contact us for free help @whatspp +8615800211936