News

-

The advantages and disadvantages of high-speed steel and cemented carbide, the difference

High-speed steel: It is high-carbon and high-alloy steel. According to chemical composition, it can be divided into tungsten series and molybdenum series steel. According to cutting performance, it can be divided into ordinary high-speed steel and high-performance high-speed steel. High-speed ste...Read more -

Carbide end mill 2

Carbide end mill 2 Milling cutter is a widely used multi-edge rotary cutter, and there are many kinds of it. According to the purpose, there are: 1) for processing planes, such as cylindrical face milling cutters, end mills, etc.; 2) for processing grooves, such as end mills, T-shaped cutt...Read more -

Carbide end mill

Carbide end mill Milling cutter is a widely used multi-edge rotary cutter, and there are many kinds of it. According to the purpose, there are: 1) for processing planes, such as cylindrical face milling cutters, end mills, etc.; 2) for processing grooves, such as end mills, T-shaped cutter...Read more -

About machining tool passivation

What is tool passivation By deburring, leveling and polishing the tool, the quality of the tool is improved and the service life is prolonged. The name of the process before the finish grinding of the tool and the coating is not uniform at home and abroad. It is called “cutting edge dulling...Read more -

What milling cutter is used to process stainless steel?

Stainless steel milling characteristics 1. Severe work hardening The work hardening of stainless steel is serious, the first choice is the mixture of austenite and ferrite is the most, the hardness of its hardening layer is 1.4~2.2 times higher than the original matrix hardness, strength R=1470~1...Read more -

60 degree milling cutter manufacturer perfect mechanism

JIALING carbide 2 spiral flute Up cut End Mill How to design a perfect 60-degree milling cutter manufacturer organization? One is project research, that is, by looking at customers, fields, opponents, and yourself, to determine what your manufacturer can do and is good at. After researching the ...Read more -

A detailed research study on the Roughing End Mills Market was recently published by IndustryGrowthInsights

A detailed research study on the Roughing End Mills Market was recently published by IndustryGrowthInsights. This is a latest report, covering the current COVID-19 impact on the market. The pandemic of Coronavirus (COVID-19) has affected every aspect of life globally. This has brought along sever...Read more -

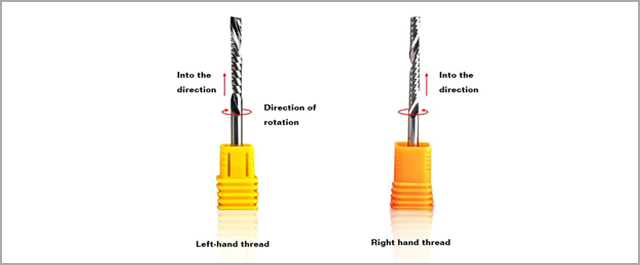

What is the difference between up end mill and down cut?

What is the difference between up end mill and down cut? End mills can be divided into up end mill and down cut. Now, many people don’t have the concept. 1、The direction of the workpiece and the rotation of the milling cutter have two kinds of milling First, We can tell by the way whether...Read more -

How to choose the right milling cutter ?

How to choose the right milling cutter ? Milling cutter, is used for milling processing the milling cutter processes the surface of the object).A rotating tool with one or more cutter teeth What principles should be followed when choosing milling cutter for machining? What do you kno...Read more