What is the difference between up end mill and down cut?

End mills can be divided into up end mill and down cut. Now, many people don’t have the concept.

1、The direction of the workpiece and the rotation of the milling cutter have two kinds of milling

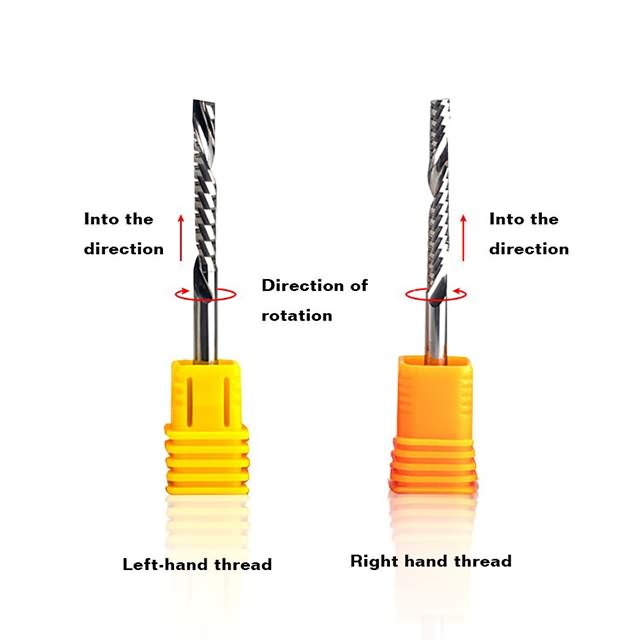

First, We can tell by the way whether it is up end mill and down cut;Facing the vertical milling cutter, if the edge groove from the bottom left to the top right rise, this is up end mill; If the groove of the blade rises from the bottom right to the top left, this is down cut. The helical edge groove ACTS as a chip receptor and also forms the front Angle and front part of the milling cutter.

Up end mill:,First of all, the up end mill is the tool rotation, milling out of the chip is to go up, and it will not plug in the slot, For acrylic, PVC,MDF, wood and a series of plates, very functional.

Down cut: It is downward rotating, It is used for cutting boards and other boards made of wood chips, without burrs on the cutting surface.

The conclusion is that for the acrylic and other plastic plate, we choose the up end mill. It is better to use down cut for wood material.

Post time: Dec-23-2019

![RNAF])QQP50B~]FO85KIZW4](https://www.thecarbidetools.com/uploads/d3a58afd.jpg)