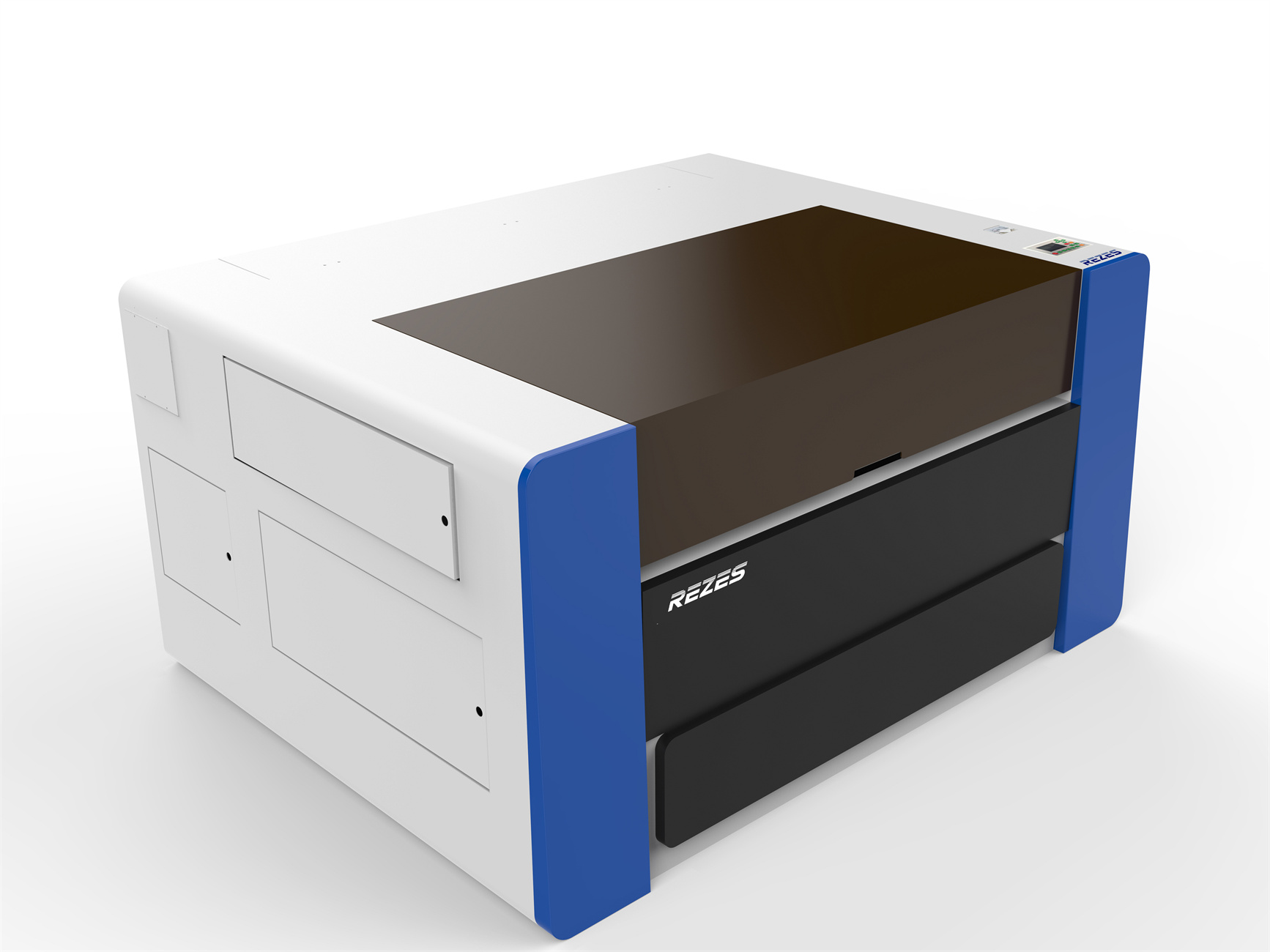

Nonmetal Laser Cutting Machine

Product Display

Technical parameter

|

Application |

Laser Cutting |

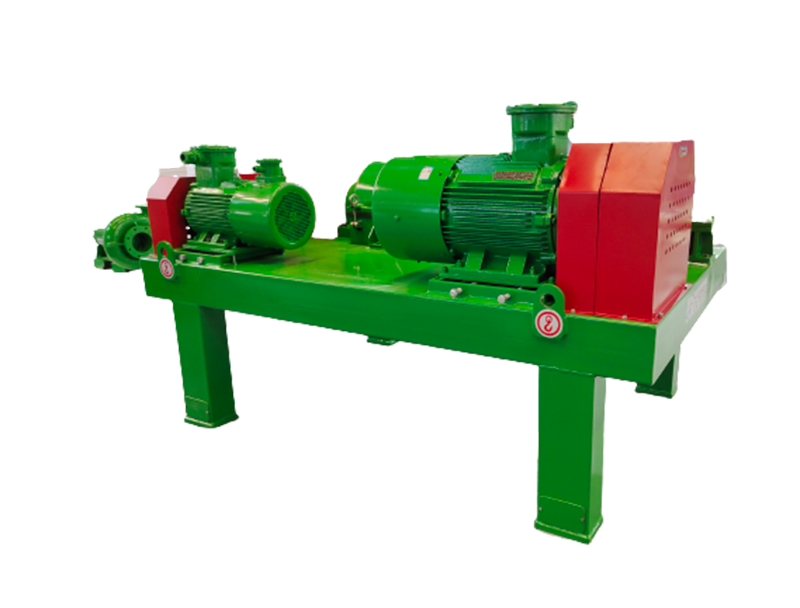

Core Components |

Laser Source |

|

Graphic Format Supported |

Ai, Bmp, Dst, Dxf, Plt, Dwg, Las, Dxp |

Cutting Area |

1300*900mm |

|

Applicable Material |

Plastic And Metal |

Cnc Or Not |

Yes |

|

Cooling Mode |

Water Cooling |

Control Software |

Ruida |

|

Graphic Format |

Ai, Plt, Dxf, Bmp, Dst, Dwg, Dxp |

Laser Power |

10W/20W/30W/50W/100W |

|

Laser Source Brand |

Efr/Reci/Yongli |

Certification |

Ce, Iso9001 |

|

Servo Motor Brand |

Leadshine |

Key Selling Points |

High-Accuracy |

|

Guiderail Brand |

Pmi |

Control System Brand |

Ruida |

|

Applicable Industries |

Hotels, Garment Shops, Building Material Shops |

Core Components |

Laser Supply |

|

Mode Of Operation |

Pulsed |

After Warranty Service |

Online Support |

|

Laser Power |

Split Design |

Positioning Method |

Double Red Light Positioning |

|

Video Outgoing Inspection |

Provided |

Graphic Format Supported |

Ai, Plt, Dxf, Dwg, Dxp |

|

Place Of Origin |

Jinan,Shandong Province |

Warranty Time |

3 Years |

Main Parts for Machine

RECI Laser Tube

Water Chiller

Power Supply

Exhaust Fan

Air Pump

Auto Focus

Ruida Control Panel

Up and down table

Machine Video

Main Feature of laser cutting machine

Main Feature of laser cutting machine:

1. Focusing is simple , can do it by touching two button, takes only 3 seconds.

2. English version Laser cut software supporting 10 commonly used graphic formats.

3. DSP off-line control with USB port interface.

4.Taiwan HIWIN square linear guide rail installed on X&Y axis, make sure the works stably and precisely.

5.The professional manufacturers adopts square tube framework in China, with more than 40% higher fuselarge strength than iron sheet structure.

This design prevents the machine from quivering, resonance and distortion during long term work.

6.New-style high-efficiency laser tube is adopted. Laser beam is more stable than the traditional type. Usage is more than 10000 hours.

7.Air asist ,we will provide you one set air compressor, you can turn up/down the switch between the laser head to control the strength of air blowing. To avoid getting fired and blow away the dusk /smoke.

8.Exhaust fan&vacuum table, this pulls fumes and debris away from the work piece; the resulting vacuum is strong enough to straighten and flatten thin materials against the work table for cutting and engraving in good focus.

9.Advanced DSP control system, with professional motion control chip, has the function of consecutively

high-speed curve cutting and the shortest path selection, which largely improves your working efficiency.

10.Automatic up-down table can be chosen for thick materials and high objects.

11.Un-limited feed-through door , we can only add the auto-feeding system allows the use of roll material and unlimited sheet length.

Cutting parameter

|

Cutting Power Speed(mm/s) Material |

60W |

80W |

100W |

150W |

|

Acrylic 3mm |

6-10 70%-90% 20-25 |

10-15 50%-80% 50-55 |

10-15 40%-80% 55-60 |

10-15 30%-80% 60-70 |

|

Acrylic 5mm |

6-8 60%-80% 8-10 |

8-15 60%-90% 15-20 |

8-15 70%-90% 20-25 |

8-15 60%-90% 25-30 |

|

Acrylic 10mm |

2 60%-85% 3-4 |

3-5 60%-85% 6-8 |

4-6 70%-90% 6-9 |

5-8 70%-90% 10 |

|

Acrylic 30mm |

|

0.4-0.6 80%-95% 0.7-0.9 |

0.4-0.8 80%-95% 0.8-1.0 |

0.6-1.0 80%-95% 0.8-1.2 |

|

Plywood 5mm |

10-20 60%-90% |

40-60 60%-85% |

50-70 65%-85%

|

50-80 50%-90% |

|

Plywood 12mm |

|

Not recommend |

5-8 70%-95% |

8-12 30%-90% |

|

MDF 6mm |

|

6-10 60%-85% |

8-15 50%-95% |

15-20 50%-90% |

|

MDF 15mm |

|

Not recommend |

2-3 80%-90% |

3-4 80%-90% |

|

Foam 2cm |

Not recommend |

50-60 75%-85% |

60-80 75%-85% |

80-100 70%-90% |

|

Leather |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Fabric |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Cloth (one layer) |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Thin Carpet |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Spongy fabric |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

400-600 20%-90% |

|

Silver laser tube cutting parameter for SS,CS |

||||||

|

Material |

Thickness |

Auxiliary gas |

220W(T1) |

300W(T2) |

500W(T3) |

600W(T4) |

|

Stainless steel |

0.5 |

Oxygen |

70 |

100 |

144 |

180 |

|

1 |

Oxygen |

18 |

60 |

96 |

110 |

|

|

2 |

Oxygen |

8 |

25 |

25 |

60 |

|

|

3 |

Oxygen |

4 |

10 |

10 |

25 |

|

|

Carbon steel |

0.5 |

Oxygen |

33 |

110 |

110 |

220 |

|

1 |

Oxygen |

25 |

80 |

80 |

150 |

|

|

2 |

Oxygen |

10 |

30 |

30 |

80 |

|

|

3 |

Oxygen |

5 |

15 |

15 |

35 |

|