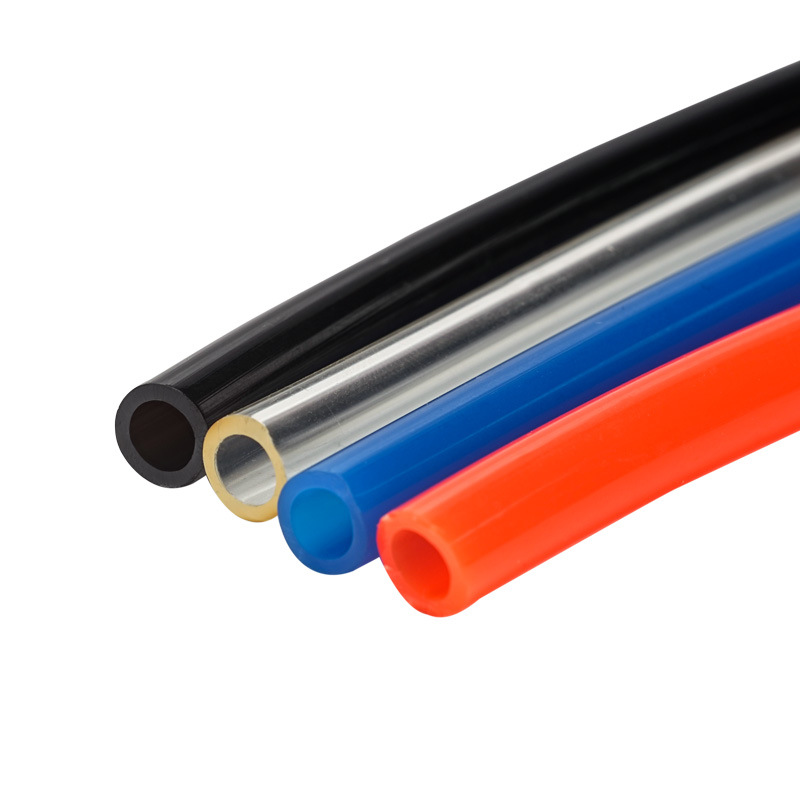

Od 8mm ID 5mm Hose Blue, Red, Transparent, Black, Sky Blue Pneumatic Pipe Air Tube PU 8X5mm PU Pneumatic Polyurethane Tubing

The Use and description of TUP pipes

Tips:

*High fluid temperature or corrosive components of fluid may cause hose rupture;

*The hose may crack if the working environment temperature is too high or there is a chemical smell in the working space;

*If the hose is stored in a damp place or the storage period is too long, it will be hydrolyzed or aged, which may lead to fracture;

*When adiabatic compression causes abnormal temperature rise, the hose may break;

*When the PU pipe is applied to the moving end of vibration and bending, the hose may break due to the temperature rise caused by the automatic heating generated by molecular heat

*Precise and high-quality products are completed by precise instruments and strict quality control.

Matters needing attention

1) Do not let the hose rub and twist, stretch and twist excessively, otherwise the hose will be damaged and the working pressure will be affected;

2) If the temperature of water or oil is too high, please use heat-resistant pipes

3) Sufficient allowance shall be reserved for the length of piping. When using quick connect, the cross section of the hose shall be flat and vertically installed

4) When bending PU pipes, pay attention to the minimum bending radius requirements

5) Before using PU pipe, please use pipe cutter to cut the pipe until the diameter is flat and round. Then press the connector vertically into the bottom and pull it to ensure successful connection

Specification Parameters

Place of Origin: Zhejiang, China

Brand Name:

Model Number: PU6*4

Specification: 12*8, 4/6/8/10/12/14/16mm

Length: 200M, 80~200M

Thickness: 1.5mm, 2.0mm

Standard: 98A 95A

Processing Service: Moulding, Cutting

Product name: PU Polyurethane Hose

Material: Polyurethane

MOQ: Negotiable

Working pressure: -0.1Mpa~1.0Mpa

Application: Pneumatic connection

Feature: High Flexibility

Color: Red/Blue/Black/Transparent

Details