ODM/OEM Service

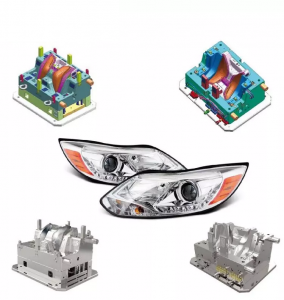

Plastic Injection Mold Making

Plastic injection molds are usually created from hardened or pre-hardened metallic, aluminum, and/or beryllium-copper alloy. Steel molds fee more, however are frequently favored due to their excessive durability. Hardened metallic molds are warmth dealt with after machining, and they may be through a long way advanced in phrases of damage resistance and lifespan. Many metallic molds are designed to procedure nicely over 1,000,000 components all through their lifetime. For decrease volumes, pre-hardened metallic molds offer a much less wear-resistant and much less costly option. Aluminum molds, on the alternative hand, can fee extensively much less, however they usually are ill-appropriate for excessive-extent manufacturing or components with slender dimensional tolerances. Nevertheless, aluminum molds can economically produce tens of lots to masses of lots of components, whilst designed and constructed the use of pc numerical control (CNC) machines or Electrical Discharge Machining (EDM) processes. Copper alloy inserts are now and again utilized in regions of the mould that require rapid warmth removal. This can lessen cycle time and enhance the cultured nice of the part.

How Are Plastic Injection Molds Made?

Molds are built thru most important methods: wellknown machining and electric discharge machining(EDM).

Standard/CNC Machining

In its conventional form, standard machining requires the manual use of lathes, milling machines and drill presses. With advanced technology, CNC machining has become the predominant means of creating more complex and accurate molds, while still using standard machining methods. With CNC, computers are used to control the movement and operation of the mills, lathes, and other cutting machines.

In modern CNC systems, the mold design and manufacturing processes are both highly automated. The mold’s mechanical dimensions are defined using computer-aided design (CAD) software, and then translated into manufacturing instructions by computer-aided manufacturing (CAM) software. “Post processor” software then transforms these instructions into the specific commands necessary for each machine used in creating the mold. The resulting commands are then loaded into the CNC machine.

Molds Design

The plastic injection mold consists of two primary components, the cavity half of the mold (A half) and the ejector half of the mold (B half). These mold halves are designed to work in conjunction as follows:

Plastic resin from the molding machine enters through a “sprue” or “gate” on the A half.

A sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine. This allows the molten plastic to flow from the barrel into the mold (or “cavity”).

The sprue bushing directs the molten plastic through channels (called “runners”) that are machined into the faces of the A and B halves of the mold.

The molten plastic flows through the runner and enters one or more specialized gates and into the cavity to form the desired part.

A mold is usually designed so that the molded part reliably remains on the B half of the mold when it opens. The runner and the sprue are drawn out of the A half. The molded part then falls freely when ejected from the B half.

A single plastic injection mold can have one cavity, producing one part at a time, to multiple cavities for extremely high-production molds (like those for bottle caps) that can have 100 plus cavities.