Oil & Gas Transport (API) Pipe Production Line

Specialized in Pipe Production Line

More than 23 years…

High Frequency (HF) longitudinal welded pipe production line / pipe making machine / tube mill is designed to produce welded pipes of 8mm to 720mm in OD and with a maximum wall thickness of 16mm, as well as corresponding square and rectangular pipe.

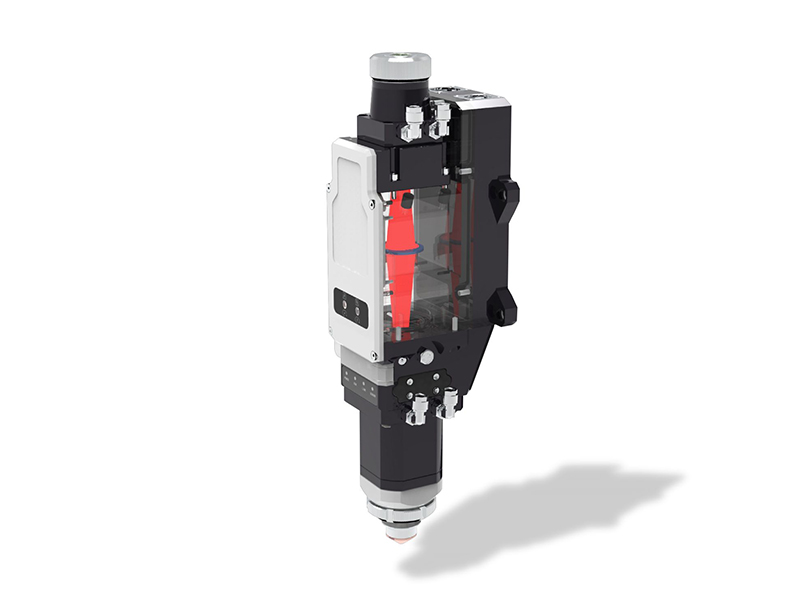

Oil & Gas Transport (API) Pipe Production Line

As an important equipment for oil and gas drilling and transportation, the special oil pipe is widely used in the connection between drill collar and bit, drilling power transmission, borehole wall support, oil and gas transportation, etc. The whole production line adopts ‘ZTF’ forming technology. With our strong manufacturing and R&D team, ZTZG has successfully developed and manufactured the world largest straight welded API pipeline with 720mm OD for Russia in 2018.

Uncoiling →Head Straightening →Shear & Welder → Accumulator →Edge Milling→ Forming → H.F. Induction Welding → Burr Removing→ Medium frequency annealing→ Cooling →Ultrasonic flaw detection→ Sizing → Cutting → End Chamfering →Hydro Testing →Weighing& Measuring& Spray →Run out table → Checking & Collecting → Accessing Warehouse

Product Information

| Line Component | Uncoiler Shear & end welder Accumulator Forming & sizing machine H.F welder Flying saw Stacking & packing machine |

| Special | Hydraulic testing machine, intermediate frequency annealing machine, ultrasonic flaw detection machine, etc. |

|

Material |

High strength steel, Low carbon steel, GI, etc |

| Strip Steel Width | 63 mm- 2400mm |

| Strip Steel Thickness | 1.2 - 4.0mm |

|

Strip Steel Coil |

Inner diameter:Φ 610-760 mm Outer diameter:Φ 1300-2300 mm Weight: Max=30.0 T |

| Round Pipe | Φ8-Φ720 mm |

| Thickness | 1.2-16.0 mm |

| Length | 6-12 m |

| Forming Speed | 10-60 m/min (Attn: Max pipe diameter thickness doesn’t correspond with the max speed) |

| Feeding Direction | Left feeding (or right feeding), option by customer |

| Electric Installed Capacity | 220-2500 kw |

| Production Line Size | 40m(length) ×3.8m (width)-400m(length) ×40m (width) |

| Color of Machines | Blue or customized |

| Yearly Out-put | 10,000-180,000 tons |

Our Advantage

· Raw materials: high strength, high toughness, and corrosion resistance

· Equipment: High precision, high universality of roller molds

· Process: Multi-process inspection and flaw detection; High-quality pipe end precision machining.

· Product: Can produce high-grade, large diameter, and large wall thickness steel pipes.

Product Application

We can design and manufacture pipe making machine according to customers’ requirements.

New Energy Industry

High-speed Guardrail

Architectural Decoration Industry

Everything you need to create a steel pipe production line

Our Certificate

Our Company

Shijiazhuang Pipe Technology Development Co., Ltd.was established in 2000 locating in Shijiazhuang, the capital city of Hebei Province. The factory covers an area of 67,000 square meters. Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

Ready for a new

Business Adventure?

Contact Now!