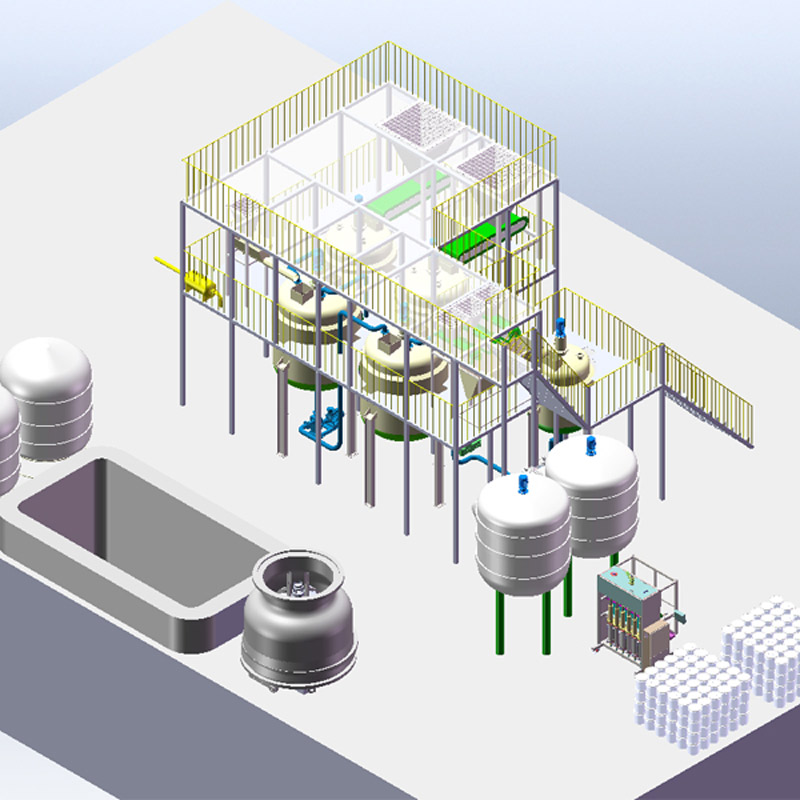

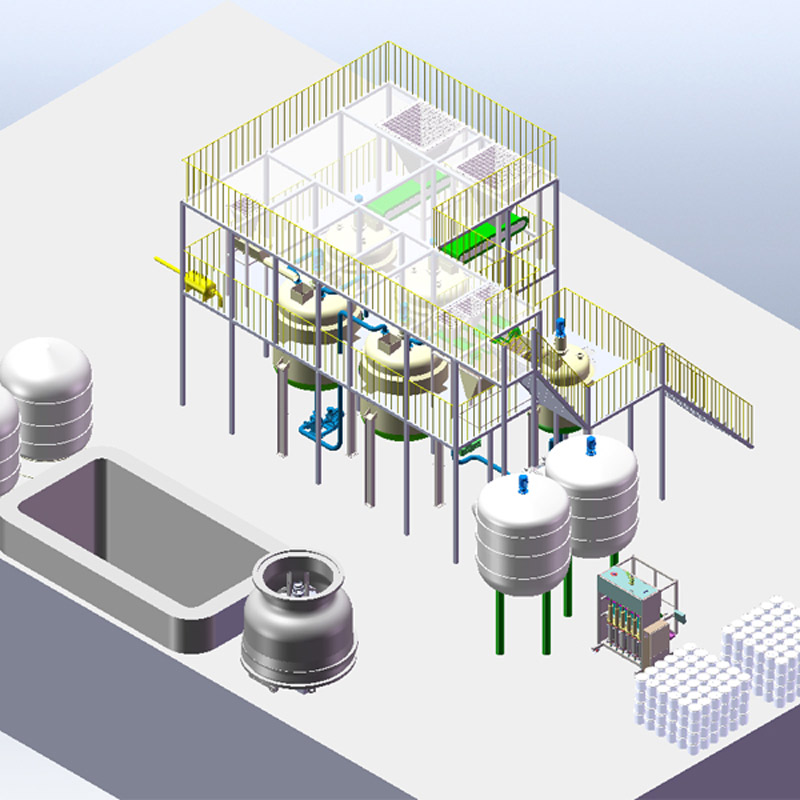

Organic Fertilizer Polishing Machine

Product introduction

The organic fertilizer polishing machine is a circular throwing device which is equipped on the basis of the granulator of organic fertilizer and compound fertilizer, which makes the particles roll into balls at one time, with no return material, high ball forming rate, good strength, beautiful and practic.

Main Technical Parameters

|

Model |

Production Capacity(t/h) |

Matching Power(kw) |

Disc Diameter(mm) |

Shape Size(mm) |

|

TDPY-800 |

1-2 |

5.5*2 |

800 |

2800*920*1290 |

|

TDPY-1000 |

2-3 |

5.5*2 |

1000 |

3100*1020*1390 |

|

TDPY-1200 |

3-5 |

7.5*2 |

1200 |

3400*1120*1490 |

|

TDPY-1500 |

5-8 |

11*2 |

1500 |

3200*1550*1600 |

Performance characteristics

- High output and flexible arrangement.Single or several granulators can be used at the same time, to solve the past granulator must be equipped with a circular casting machine brought by the complex technology, equipment investment and other disadvantages.

- The finished products have the same granularity and high yield.The machine is composed of two or more throwing cylinders arranged in sequence, and the material is discharged from the discharge port after several rounds of throwing. The finished product has the same particle size, high density, roundness and smoothness, and high yield.

- Simple structure, easy operation and maintenance.Make cylindrical particles rolling into a ball, no return material appearance beautiful, simple structure, safe and reliable, easy operation and maintenance, according to the manual can be operated.

- Strong adaptability, low cost and high benefit.Anti – overload ability, can adapt to all kinds of environment.

Working principle

This organic fertilizer polishing machine is composed of two or more throwing cylinders arranged in sequence. After repeated centrifugal throwing, the material is discharged from the discharge port.

Write your message here and send it to us