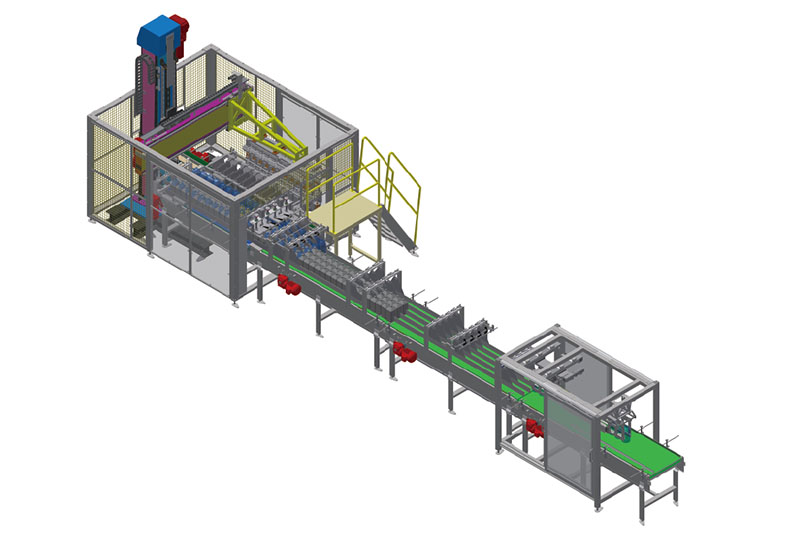

Panel Mesh Welding Machine

Panel Mesh Welding Machine

· Pneumatic type

· Automatic production line

· High speed the latest design

The BRC mesh welding machine adopts Pneumatic welding technology and the speed is max. 100 times per minute. Welded parameters are controlled through the HMI interface. Welded parameters are controlled through the HMI interface.

3-8mm mesh welding machine is used to make steel rebar mesh, road mesh, building construction mesh, etc. The concrete reinforcing mesh machine is suitable for the economical production of light and heavy mesh panels.

Panel mesh welding machine Parameter

|

Model |

DP-FM-2500A |

DP-FM-2500A+ |

DP-FM-3000A |

|

Max. mesh width |

2500mm |

2500mm |

3000m |

|

Line wire dia(Pre-cut) |

3-8mm |

3-8mm |

3-8mm |

|

Cross wire dia(Pre-cut) |

3-8mm |

3-8mm |

3-8mm |

|

Line wire space |

100-300mm |

3-6mm,50-300mm 6-8mm,100-300mm |

100-300mm |

|

Cross wire space |

50-300mm |

50-300mm |

50-300mm |

|

Max. mesh length |

6m/12m |

6m/12m |

6m/12m |

|

Max. welding space |

80-100 times/min |

80-100 times/min |

80-100 times/min |

|

Welding electrodes |

24pcs |

24pcs |

30pcs |

|

Welding transformer |

150kva*6pcs |

150kva*9pcs |

150kva*8pcs |

|

Weight |

6.8T |

7.4T |

7.5T |

Panel mesh welding machine Video:

Panel mesh welding machine advantages:

|

Line wire feeding: |

|

|

Option 1: Line wires are fed from wire pay-off (bear 1T) automatically, then through first straight setting roller device. The wire storage device can feed the longitude wires step by step, then through second straight setting roller device. |

|

|

Wire pay-off for max.1T material |

First straight setting rollers |

|

Wire storage device |

Second straight setting rollers |

|

Option 2:The line wire need to pre-straightened and pre-cut. Then manually put input the wire feeding system. The production same as coil feeding. |

|

|

Cross wire feeding: Cross wires should be pre-straightened&pre-cut, then the workers put the cross wires on the cross wire storage device, which can bear maximum 1T wires. There is one motor& hardened reducer that feed a bulk of wires to the insider feeder continuously. Step motor controls cross wire falling, big torque, more accurate and stable. |

|

|

Cross wire feeder |

Step motor |

|

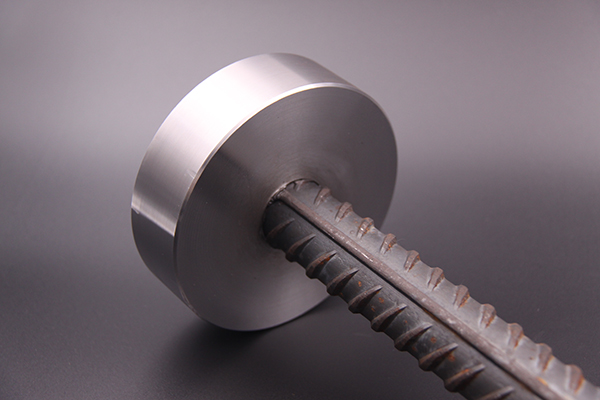

Upper copper arm connect two welding electrodes, much easier for electric conduction. (European design) SMC 63 multi-force&energy-saving air cylinders |

Separate control technology, one electric board and one SCR controls one welding transformer. |

Panel mesh application

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Equipment maintenance

| A. Lubrication liquid is added regularly. B. Checking electric cable connection every month. |

Certification

FAQ

Q: What are the accepted payment methods?

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

Q: How to transport different type of machine?

A: Normally 1 set of machine need 1x40GP or 1x20GP+ 1x40GP container, decide by the machine type and auxiliary equipment you choose.

Q: The production cycle of the razor barbed wire machine?

A: 30-45days

Q: How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

Q: How long is the warranty period of the razor barbed wire machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.

Q: What’s the different between the pneumatic type welding machine and mechanical type?

A:

1. The welding speed is faster.

2. The quality of finished mesh is better due to same welding pressure.

3. Easy to adjust mesh opening by electric-magnet value.

4. Easier to maintain and repair.