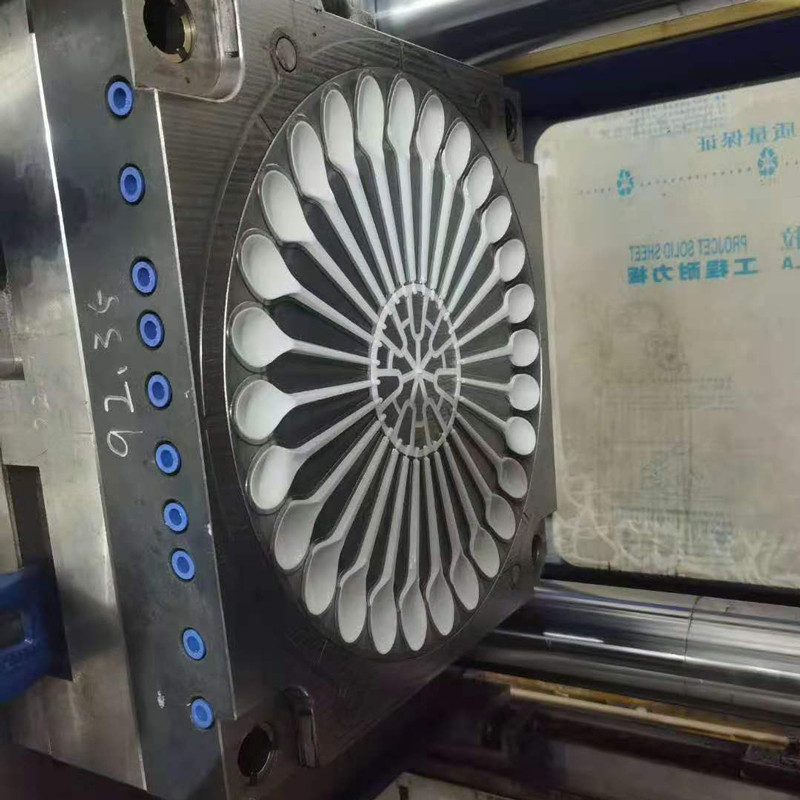

Plastic Spoon Mould

Core & Cavity Steel: H13, S136 etc or according to customer’s require.

Product material: PP, PS etc or according to customer’s require.

Mould base: S50C or LKM

Cavity: 16, 24, 32, 48, 64

Runner: hot runner / Cold runner

Mould Life: More than 1 million shots

Specification: All size of available

Design Software: UG, CATIA, PROE, OUT CAD

Packing: Wooden case

Shipment: FOB Ningbo / shanghai

Mould fully automatic running, fine cooling system

Plastic Injection spoon Mold

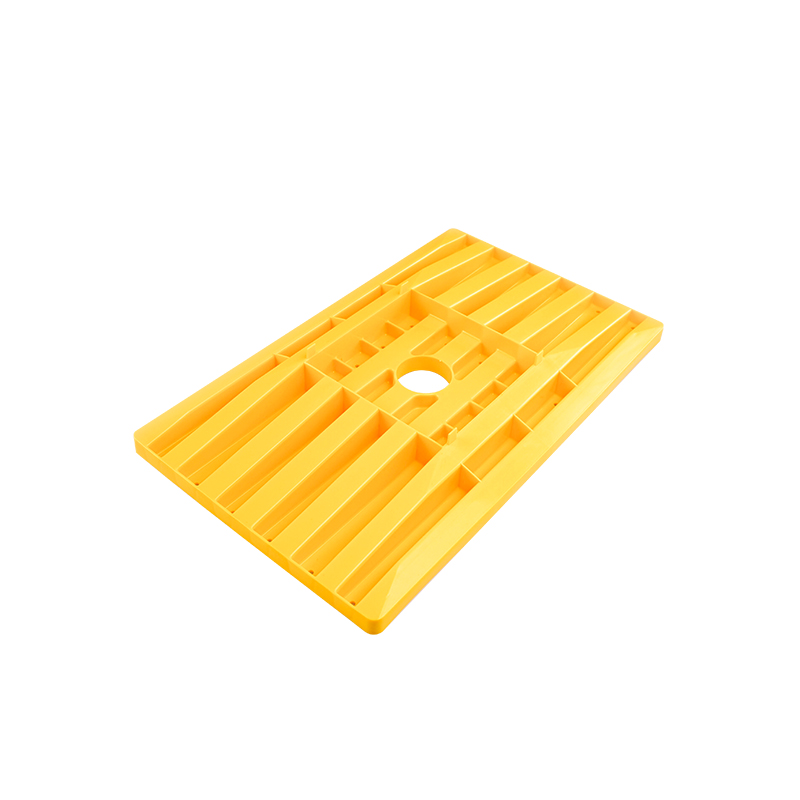

Equipment

FAQ

Q: Do you make molds for many plastics poon mould?

A: Yes, we make molds for many spoon mould, stacking spoon mould, disposable spoon mould

Q: Do you have injection molding machines to produce parts?

A: Yes, we have our own injection workshop, so we can produce and assemble according to customer requirements.

Question: What kind of mold do you make?

A: We mainly manufacture injection molds, but we can also manufacture compression molds (for UF or SMC materials) and die casting molds.

Q: How long does it take to make a mold?

A: Depending on the product size and the complexity of the parts, it is slightly different. Generally speaking, a medium-sized mold can complete T1 within 25-30 days.

Q: Can we know the mold schedule without visiting your factory?

A: According to the contract, we will send you the mold production plan. During the production process, we will update you with weekly reports and related pictures. Therefore, you can clearly understand the mold schedule.

Q: How do you guarantee the quality?

A: We will appoint a project manager to track your molds, and he will be responsible for each process. In addition, we have QC for each process, and we will also have a CMM and online inspection system to ensure that all components are within tolerance.

Q: Do you support OEM?

A: Yes, we can produce through technical drawings or samples.