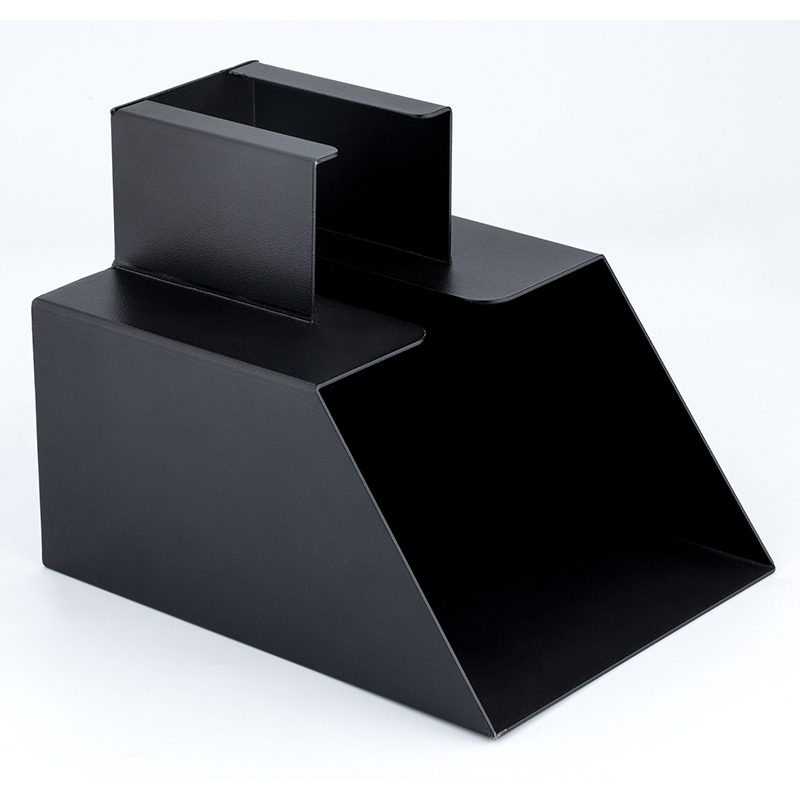

Precision Machining

CNC Milling

3-axis, 4-axis, 5-axis machining

CNC milling can help you to achieve high precision, high efficiency and repetitive processing, and can handle various complex shapes, large and small workpieces to reduce manual operations, improve production efficiency and quality, reduce production cycles and manufacturing costs.

| Machine Name | Brand | Place Of Origin | Maximum Machining Stroke (mm) | Quantity | Precision (mm) |

| Five-Axis | Okuma | Japan | 400X400X350 | 8 | ±0.003-0.005 |

| Five-Axis High-Speed | Jing Diao | China | 500X280X300 | 1 | ±0.003-0.005 |

| Four Axis Horizontal | Okuma | Japan | 400X400X350 | 2 | ±0.003-0.005 |

| Four Axis Vertical | Mazak/Brother | Japan | 400X250X250 | 32 | ±0.003-0.005 |

| Gantry Machining | Taikan | China | 3200X1800X850 | 6 | ±0.003-0.005 |

| High Speed Drilling Machining | Brother | Japan | 3200X1800X850 | 33 | - |

| Three Axis | Mazak/Prefect-Jet | Japan/China | 1000X500X500 | 48 | ±0.003-0.005 |

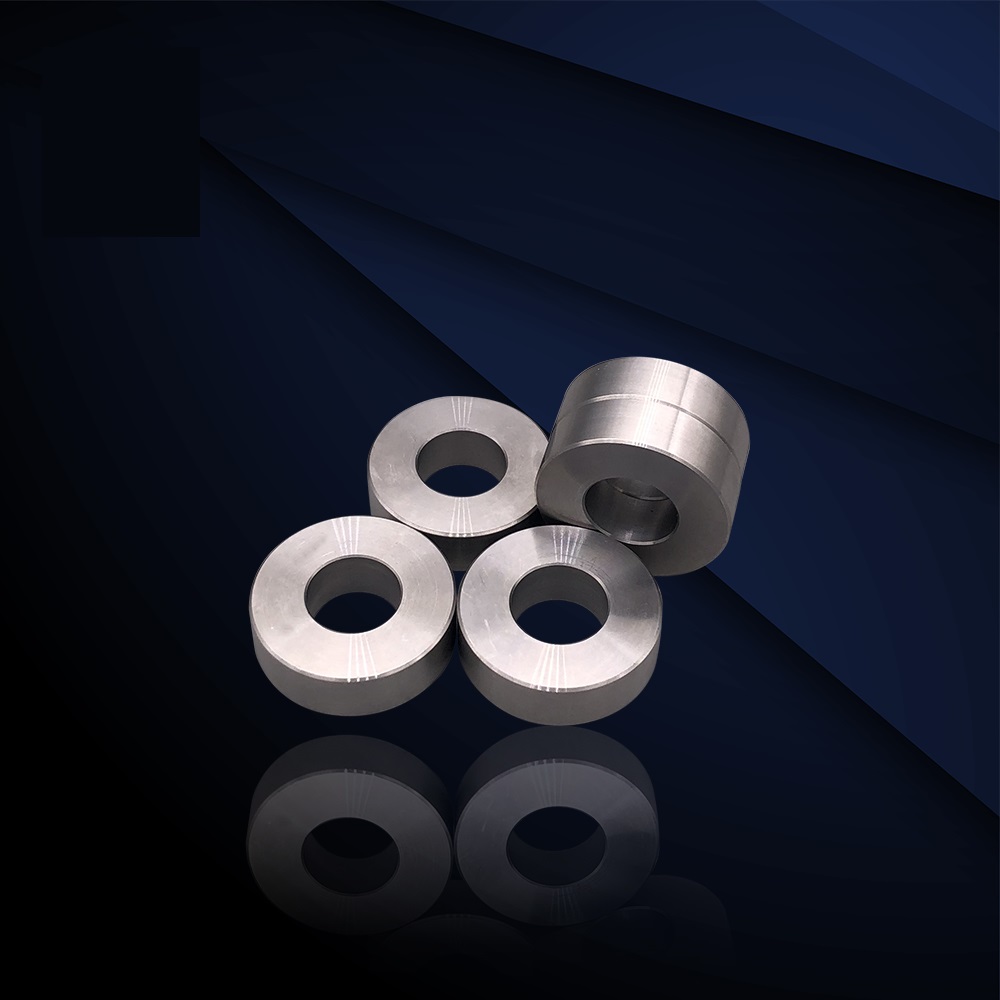

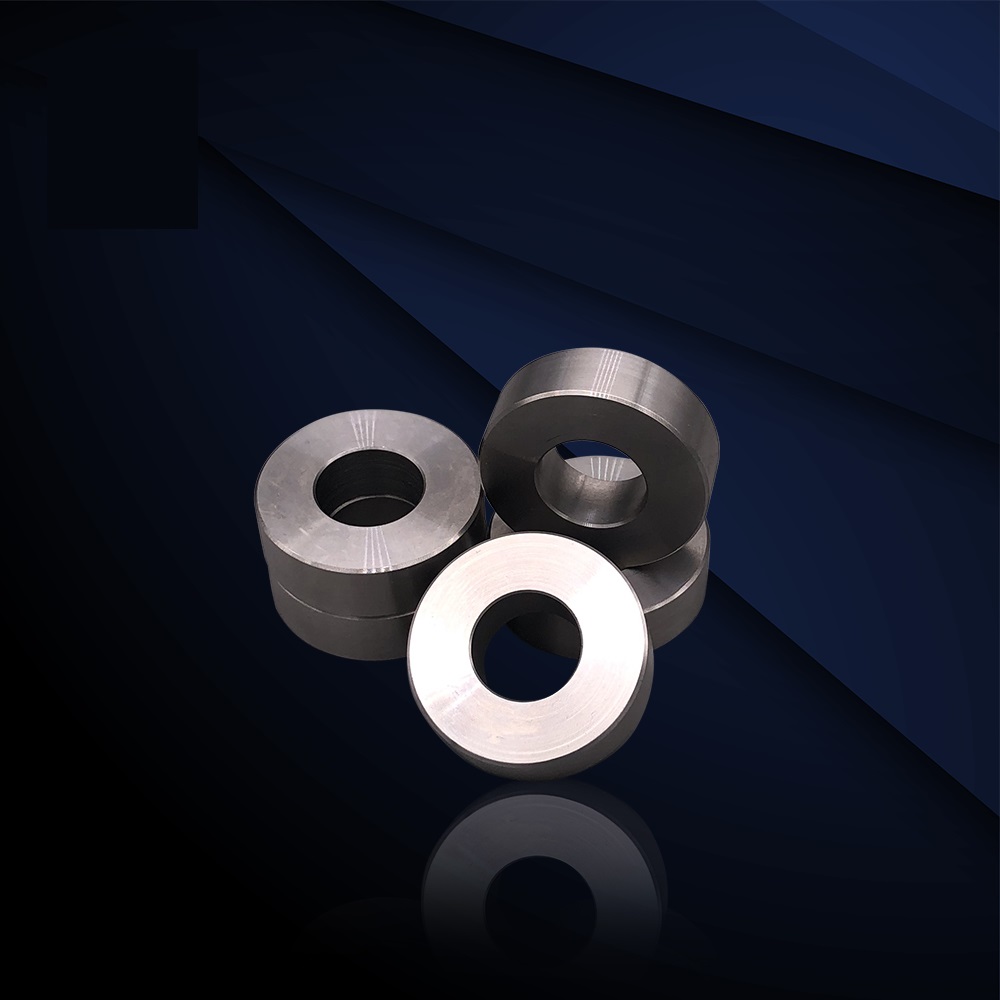

CNC Turning

CNC lathe, core walking, cutter machine

CNC Turning is widely used in the processing of workpieces in the fields of automobiles, machinery, aviation and aerospace. In the discrete manufacturing industry, CNC Turning is one of the key technologies to help you to achieve high-volume, high-precision processing.

| Machine Type | Machine Name | Brand | Place Of Origin | Maximum Machining Stroke (mm) | Quantity | Precision (mm) |

| CNC Turning | Core Walking | Citizen/Star | Japan | Ø25X205 | 8 | ±0.002-0.005 |

| Knife Feeder | Miyano/Takisawa | Japan/Taiwan, China | Ø108X200 | 8 | ±0.002-0.005 | |

| CNC Lathe | Okuma/Tsugami | Japan/Taiwan, China | Ø350X600 | 35 | ±0.002-0.005 | |

| Vertical Lath | Goodway | Taiwan, China | Ø780X550 | 1 | ±0.003-0.005 |

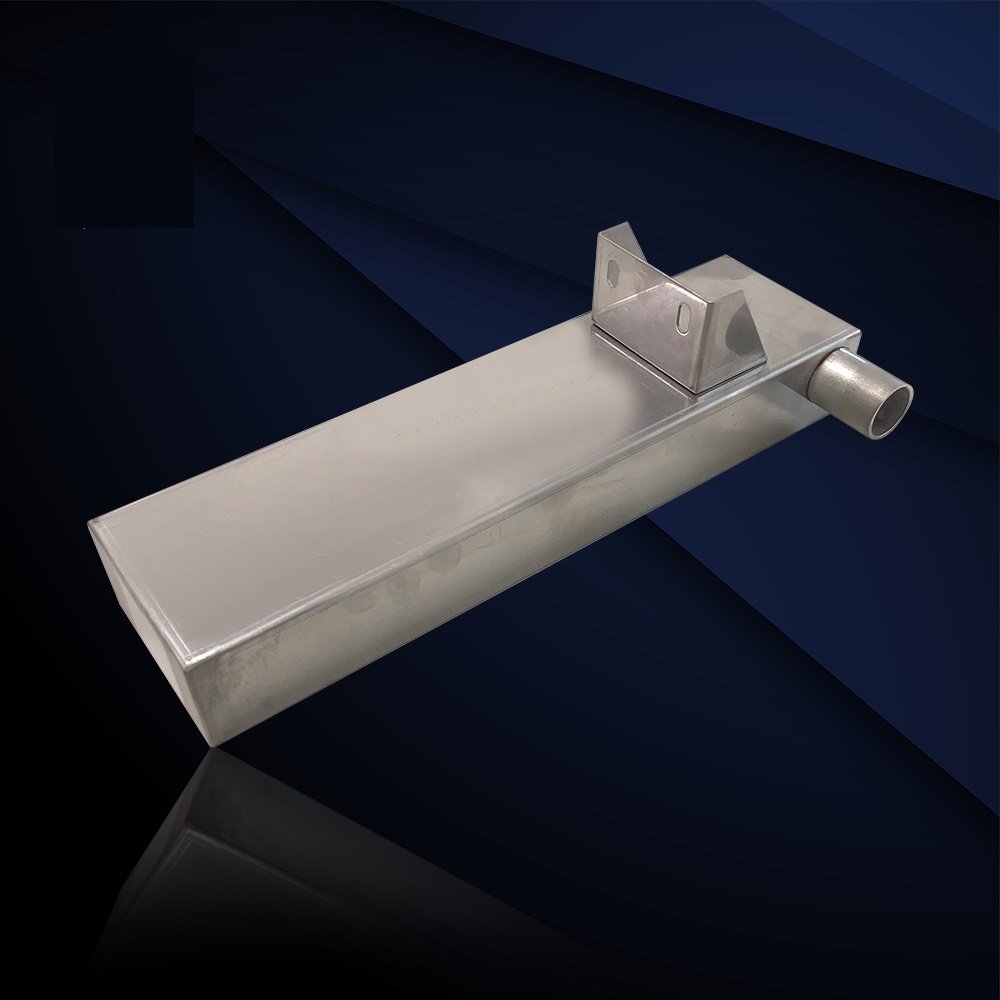

Grinding & Wire Cutting

Improving the machining accuracy and quality

Precision machining auxiliary technology, such as grinding and wire cutting, can provide more precise machining tools and methods, which can control errors during the machining process, thereby improving the machining accuracy and quality of parts by more diversified processing methods and technologies. It can process parts of various shapes and materials, and also expand processing capacity and scope.

| Machine Type | Machine Name | Brand | Place Of Origin | Maximum Machining Stroke (mm) | Quantity | Precision (mm) |

| CNC Grinding | Big Water Mill | Kent | Taiwan, China | 1000X2000X5000 | 6 | ±0.01-0.03 |

| Plane Grinding | Seedtec | Japan | 400X150X300 | 22 | ±0.005-0.02 | |

| Internal And External Grinding | SPS | China | Ø200X1000 | 5 | ±0.005-0.02 | |

| Precision Wire Cutting | Precision Jogging Wire | Agie Charmilles | Switzerland | 200X100X100 | 3 | ±0.003-0.005 |

| EDM-Processes | Top-Edm | Taiwan, China | 400X250X300 | 3 | ±0.005-0.01 | |

| Wire Cutting | Sandu/Rijum | China | 400X300X300 | 25 | ±0.01-0.02 |

Materials

Diversified CNC processing materials

● Aluminum alloy: A6061, A5052, A7075, A2024, A6063 etc.

● Stainless steel: SUS303, SUS304, SUS316, SUS316L, SUS420, SUS430, SUS301, etc.

● Carbon steel: 20#, 45#, etc.

● Copper alloy: H59, H62, T2, TU12, Qsn-6-6-3, C17200, etc.

● Tungsten steel: YG3X, YG6, YG8, YG15, YG20C, YG25C, etc.

● Polymer material: PVDF, PP, PVC, PTFE, PFA, FEP, ETFE, EFEP, CPT, PCTFE, PEEK, etc.

● Composite materials: carbon fiber composite materials, glass fiber composite materials, ceramic composite materials, etc.

Finishes

Flexibly finishes process on request

● Plating: Galvanized, gold Plating, nickel plating, chrome plating, zinc nickel alloy, titanium plating, Ion plating, etc.

● Anodized: Hard oxidation, clear anodized, color anodized, etc.

● Coating: Hydrophilic coating, hydrophobic coating, vacuum coating, diamond like carbon(DLC), PVD (golden TiN, black:TiC, silver: CrN).

● Polishing: Mechanical polishing, electrolytic polishing, chemical polishing and nano polishing.

Other custom processing and finishes on request.

Heat Treatment

Vacuum quenching: The part is heated in vacuum and then cooled by gas in the cooling chamber. Neutral gas was used for gas quenching, and pure nitrogen was used for liquid quenching.

Pressure relief: By heating the material to a certain temperature and holding it for a period of time, the residual stress inside the material can be eliminated.

Carbonitriding: Carbonitriding refers to the process of infiltrating carbon and nitrogen into the surface layer of steel, which can improve the hardness, strength, wear resistance and anti-seizure of steel.

Cryogenic treatment: The liquid nitrogen is used as the refrigerant to treat the material below-130 °C, so as to achieve the purpose of changing the material properties.

Quality Control

Target: Zero defects

Parts process flow & quality control procedure:

1. Document control team manage all the drawings to guarantee the security of customer confidential information, and keep the record traceable.

2. Contract review, order review and process review to ensure fully understand client’s requirement.

3. ECN control, ERP bar-code (related to worker, drawing, material and all process). Implement SPC, MSA, FMEA and others control system.

4. Implement IQC,IPQC,OQC.

| Machine Type | Machine Name | Brand | Place Of Origin | Quantity | Precision(mm) |

| Quality Inspection Machine | Three Coordinates | Wenzel | Germany | 5 | 0.003mm |

| Zeiss Contura | Germany | 1 | 1.8um | ||

| Image Measuring Instrument | Good Vision | China | 18 | 0.005mm | |

| Altimeter | Mitutoyo/Tesa | Japan/Switzerland | 26 | ±0.001 -0.005mm | |

| Spectrum Analyzer | Spectro | Germany | 1 | - | |

| Roughness Tester | Mitutoyo | Japan | 1 | - | |

| Electroplating Film Thickness Meter | - | Japan | 1 | - | |

| Micrometer Caliper | Mitutoyo | Japan | 500+ | 0.001mm/0.01mm | |

| Ring Gauge Needle Gauge | Nagoya/Chengdu Measuring Tool | Japan/China | 500+ | 0.001mm |