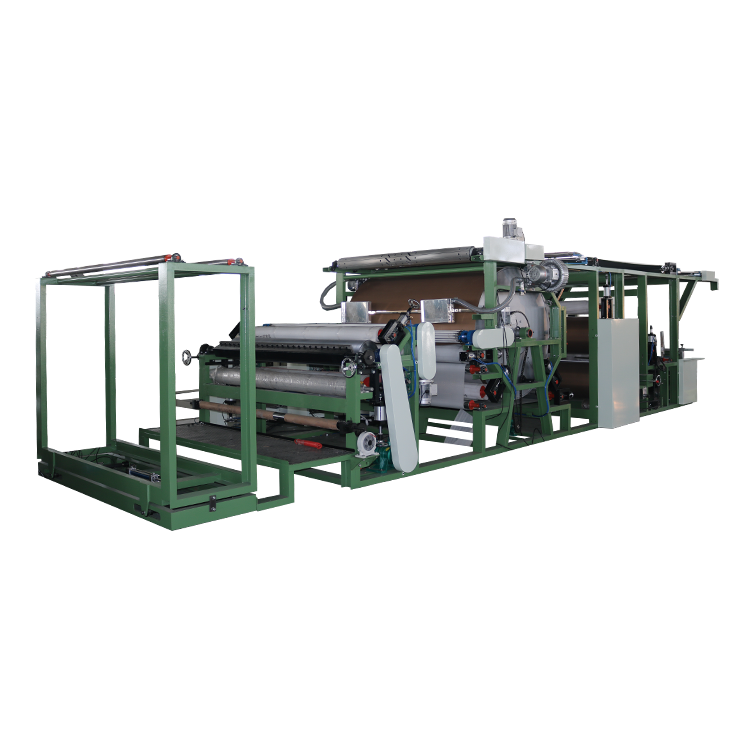

PU glue sofa fabric laminating machine

★ Use glue as a binder, and the use of glue dot transfer technology in the form of evenly transferred to the fabric on the fabric, and then with the fabric to make it into one. laminated material feel soft, breathable, fastness good, washable, dry cleaning.

★ Feeder is equipped with automatic hydraulic correction device, pneumatic correction device, conveyor belt, sub-wire device, the opening device, blowing device, with high automation procedures, effectively reduce the operator, reduce equipment costs.

★ The machine with a cooling device, so that the laminated material to reduce the temperature quickly to ensure better laminated effect.

★ The machine use frequency linkage, to achieve the whole machine synchronous speed, so that the machine has a better handling.

| Effective width | 1800 mm |

| Gluing method | Glue point transfer |

| Drying cylinder diameter | 1500 mm |

| Drying tube width | 1800 mm |

| heating method | Electric heating |

| Total power | About 60 kVA |

| Laminated speed | 0~45 m/min |

| Power supply | 3-phase 380V, 50HZ |

1.Q:Are you a factory or trading company?

A: Yes,we are a factory. you are most welcomed to visit us

2.Q:Where is your factory located?

A: Our factory is located in Yancheng City, Jiangsu Province, China, about 4 hours from Shanghai.All clients, are warmly welcome to visit us!

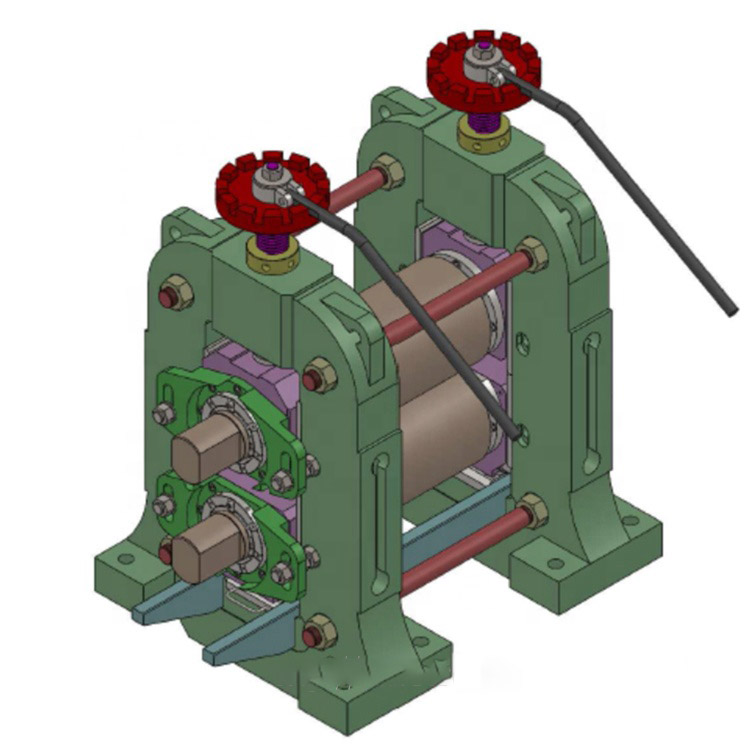

3.Q:What is the material of your products?

A: The material is mainly steel,Cast iron(Ductile cast iron) We can also choose material as customer`s requirements.

4.Q: What is your MOQ of this item?

A: 1 set per style

5.Q: What is the lead time?

A: It depends on your order quantity. Normal size laminating machine costs 20 days,and large sizes asks for 2 months.

6.Q: Is it all right to make customer’s own brand name?

A: That’s all right to make your own brand name.