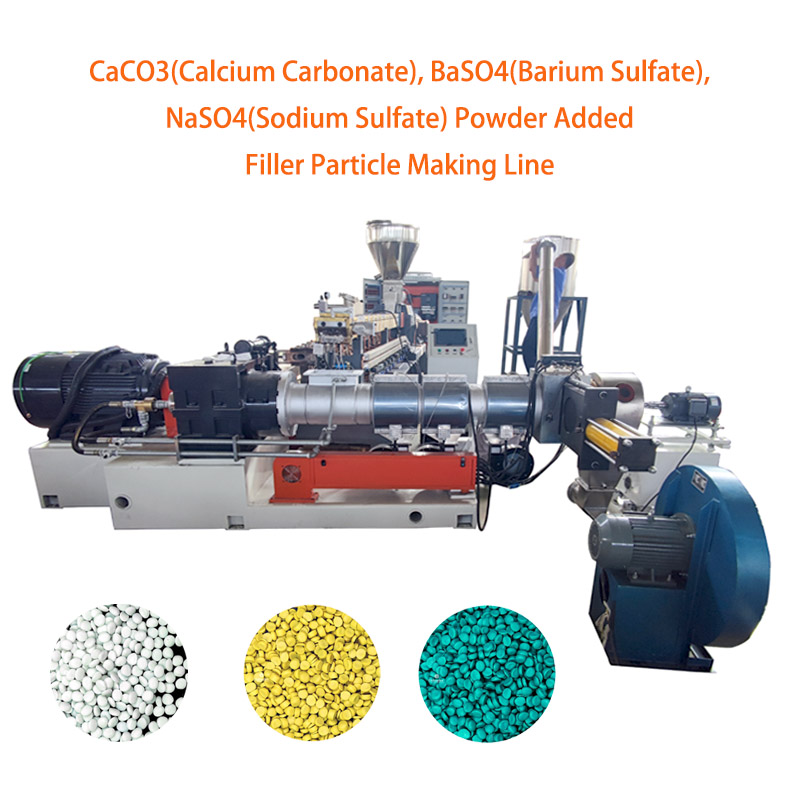

PVC cable extruder Two stage plastic polymer extruder high concentration filler and color masterbatch machine

Air cooling hot-face cutting system extruder

PVC cable extruder Two-stage plastic polymer extruder high concentration filler and color masterbatch machine

HS CODE: 8477.2010

Application(Purpose): This PVC cable extruder machine is an extrusion group used for: heat sensitive material and high percentage added filler, CaCo3 (Calcium Carbonate) powder, BaSo4(Barium Sulfate) powder, Talcum powder, black carbon Etc.

Water cold strands pelletizing system

More Details about the air-cooling hot-face cutting system twin screw extruder:

PVC classification

PVC insulated cable material

PVC sheathed cable material

Flame retardant PVC insulated cable material

Flame retardant PVC sheathed cable material

PVC elastomer cable material

PVC outdoor overhead insulated cable

Other classification

Air–cooling hot-face cutting system twin screw plastic extruder

PVC cable material is made of polyvinyl chloride as the base resin, adding stabilizer, dioctyl phthalate, diisodecyl phthalate, dioctyl terephthalate, trioctyl phthalate and other plasticizer as well as calcium carbonate and other inorganic fillers, additives and lubricants and other additives, after mixing and kneading extrusion and prepared particles.

PVC cable material processing technology

The length length ratio (L/D) of SHJ-65B twin screw is 32-40;

D-150 single screw length-diameter ratio(L/D) required at 9-11;

single screw axis has a water running channel in the middle; –>Hydraulic screen change –> Extrusion die-head designed by push and pull one; (Do PVC elastomer with this nose is there will be a phenomenon of clay) –>The air-cold hot-face cutting system –> The first section of the cyclone separator –>1#Vibrating sieve–>The second section of the cyclone separator –> 2#Vibrating sieve–>The third section of the cyclone separator –> extended vibrating screen –>Silo(if you need pack the bags then set an Automatic packaging machine(finish);

Write your message here and send it to us