Roll Mold of High Frequency Welded Pipe Unit

Finished shape

Schematic diagram of the flight

product description

According to customer requirements, using CAD/CAM technology, relying on the technology synchronized with the world, through the world’s advanced design software and rich design experience verification, scientifically optimize the design, strictly select raw materials, fine processing, vacuum heat treatment, careful inspection, production The whole process is controlled to ensure 100% factory qualified.

Mold material

Detailed description

Processing technology: optimized design – careful material selection (solemnly promise that all applied materials comply with GB/T12999 and ASTM A681) – initial cold machining rough turning (skilled machine tool operators process in strict accordance with the drawings) – special hot machining heat treatment (vacuum heat treatment is adopted, with uniform hardness and longer service life) – precision machining (high-precision CNC lathe, to ensure the accuracy requirements of products) – fine grinding – polishing – quality inspection (professionals conduct 100% testing of all products) – Packaging – after-sales service (experienced engineers provide all-round technical support) and other processes.

Detailed description

High frequency welded pipe mode roll is a necessary hardware accessory for manufacturing metal straight seam welded pipe. Under the action of the external force of the welded pipe mold, the steel coil is gradually broken and cold-rolled and rolled in the arc of the mold, and then welded to obtain a closed welded pipe. Molds can be designed according to customer needs, such as round, oval, square, rectangular, special-shaped, etc. Welded pipe molds are widely used in the production of decorative pipes, industrial pipes, and ERW welded pipes.

Product application

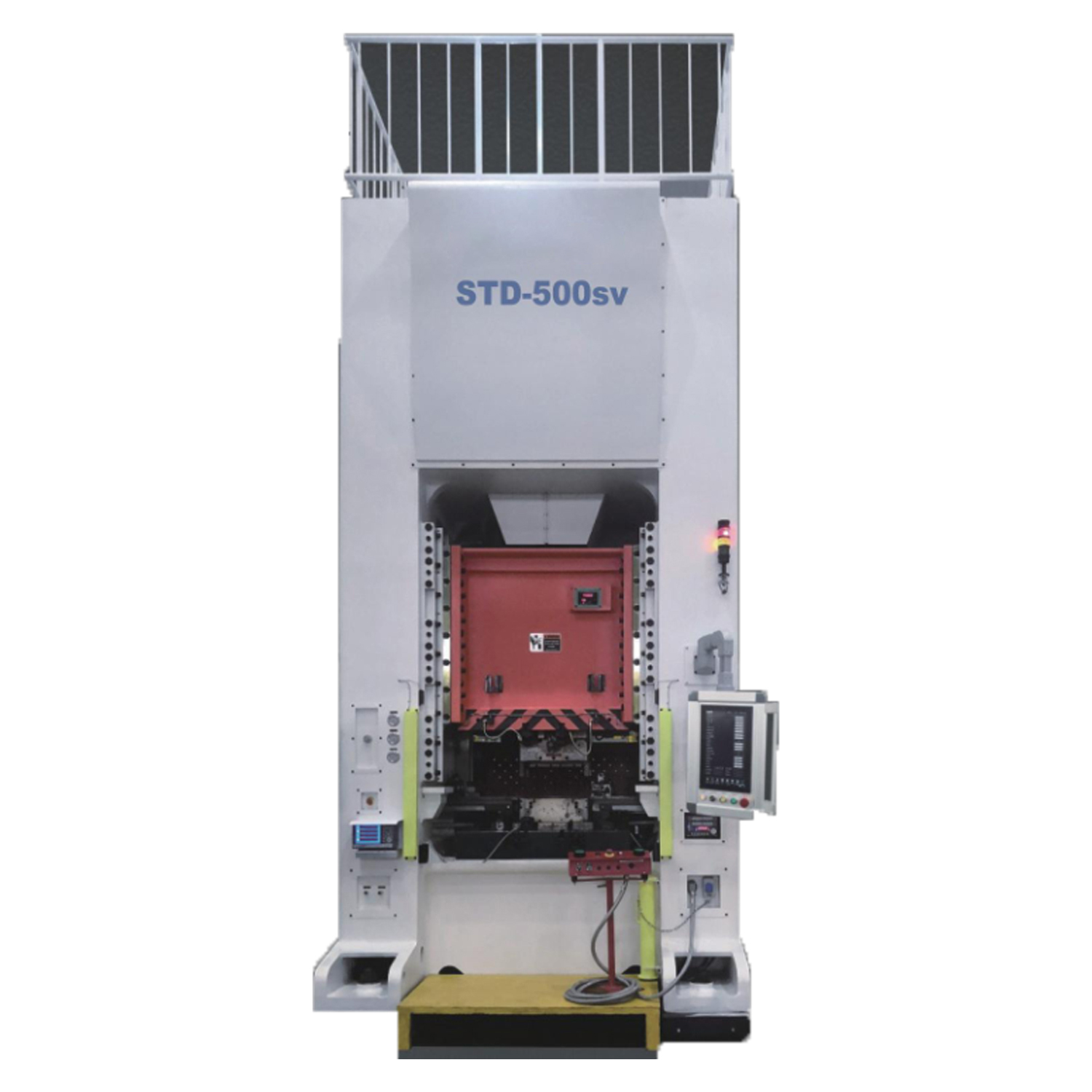

The roll mold of high-frequency welded pipe unit is an important part of the welded pipe unit, and it is also the technical core of the welded pipe process. The commonality level of forming roll is the core symbol of the process level. In the market of high-frequency welded pipe products, only by improving the commonality of forming rolls, achieving multiple uses of one roll, fast roll change, and less downtime, can we adapt to the market characteristics of high efficiency, multiple varieties, small batches, and personalization. The roll mold produced by our company has this common feature. Some applied equipment and products are as follows:

application

raw material chemical composition

After-sale service

Our company has a group of senior after-sales personnel with rich experience, which can well solve all kinds of mold repair problems, and strongly support the satisfaction of the company’s users. Strictly abide by the provisions of the contract and provide customers with continuous maintenance and replacement of molds during the after-sales service period. After the warranty period, considering the continuity of the production products of the welded pipe equipment, it is recommended that customers sign a maintenance contract with our company to ensure the technical support and management support necessary for the normal operation of the welded pipe equipment line.

After sales service period = warranty period + quality maintenance period

Quality assurance period: during the quality assurance period, if the mold cracks due to quality problems, it will be replaced free of charge. If the failure is caused by non quality problems, the mold cost will be charged.

Quality maintenance period: after the quality assurance period, it enters the quality maintenance period.

ONE-STOP SERVICE SYSTEM

Logistics packaging

The export moulds of our company all adopt professional export packing wooden cases. Because the Customs has certain requirements for the export wooden cases when they are exported, the appearance of our wooden cases is smooth, without scratches, and the color is consistent. The raw materials of wooden cases can be inspection free plates that meet the export requirements. Usually, composite plates with a thickness of 9mm-15mm are used, some of which are also called plywood or plywood. They can also be wooden cases made of solid wood, which are then fumigated and disinfected, and formal fumigation treatment is issued to meet the export requirements.

Tips

what is the role of each roller in the front row of the high frequency welded pipe unit?

The pass design of cold roll forming roll refers to the design of forming method and tool for forming plate and strip into qualified profile by continuous cold roll forming. Pass design is the basis of cold roll forming process and roll shape design.

The factors that affect the L-shape design are the structure and capacity of the forming unit, the performance of the blank, the user’s requirements for dimensional tolerance and other quality indicators. The less cold roll forming passes, the less roll pairs are required. In the case of less forming passes, the bending angle needs to be increased, but the bending angle is not allowed to exceed the allowable value. The allowable value of bending angle depends on the following factors: the deformation capacity of the blank metal, the structure and pass of the forming roll, the conditions for the blank strip to enter the pass, etc.