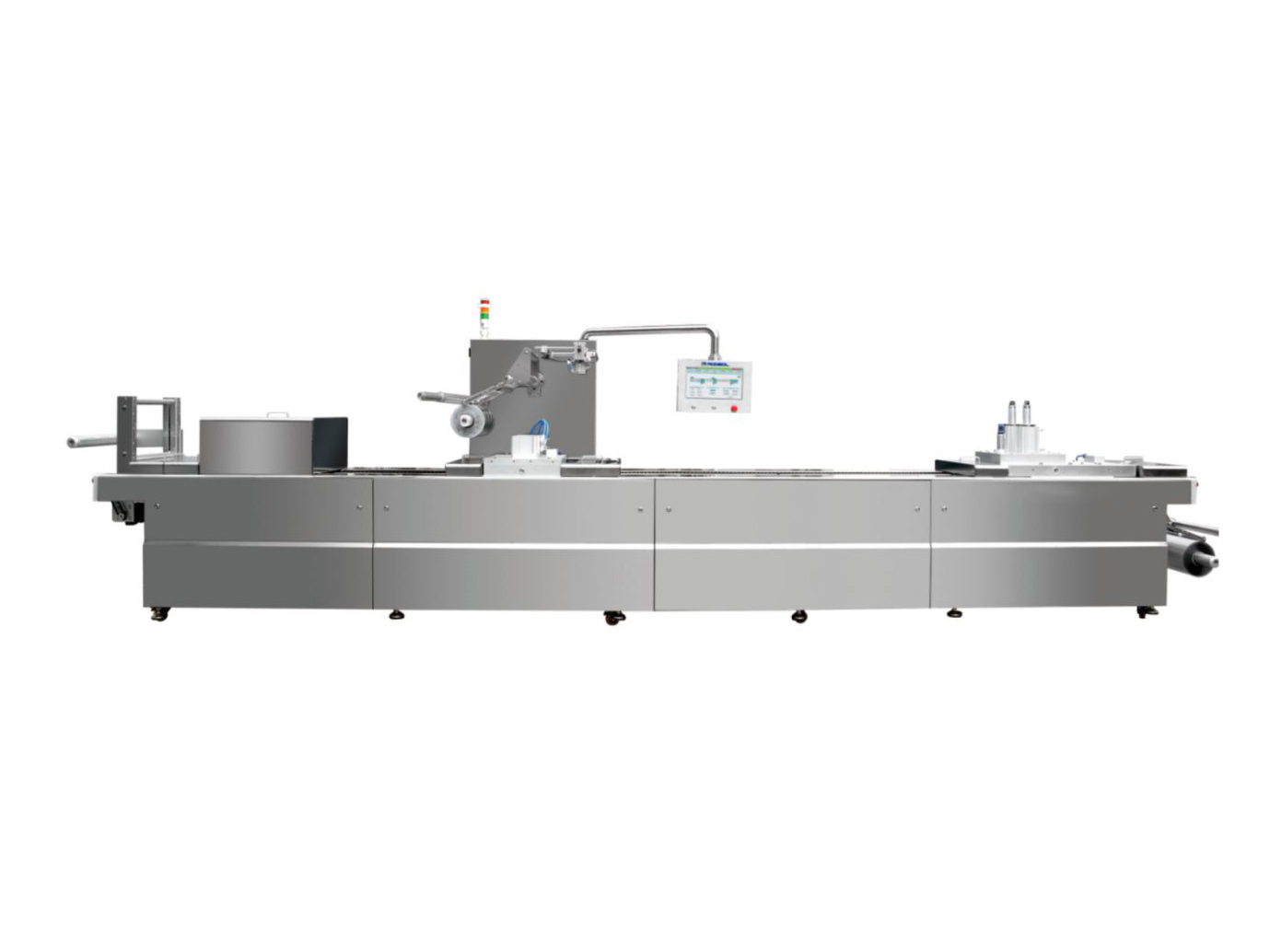

RS425H Thermoforming Machine -Rigid Bottom Film

Product Description

Automatic Thermoforming Packaging Machine applied to MAP packaging for large-scale mass-production. Thermoforming Packaging Machine consists of Framework, Automatic mold, Gas-mixer, Fresh keeping gasdisplacement system, Rigid Film delivery mechanism,cover Fllim feeding mechanism, Waste Flim recycling mechanism, Sealing system,Automatic conveyor,Servocontrol system.It can be widely used in fresh meat,cooked meat, fruit&vege,seafood, center kitchen, dry food, daily chemical, medicine, ice cream and so on.

In today’s fast-paced world, the need for efficient, innovative packaging solutions has become more important than ever. Thermoforming packaging machines have emerged as a game-changing solution as businesses strive to meet the changing needs of consumers. This cutting-edge technology provides a flexible tray sealer capable of Modified Atmosphere Packaging (MAP) with rigid base films, creating ideal packaging solutions for various industries.

Specification

|

Type RS425H |

|||

| Dimensions (mm) | 7120*1080*2150 | The largest bottom film (widthmm) | 525 |

| Size of Molding(mm) | 105*175*120 | Power supply (V / Hz) | 380V,415V |

| One cycle time(s) | 7-8 | Power (KW) | 7-10KW |

| Packing speed (trays / hour) | 2700-3600(6trays/cycle) | Height of Operation(mm) | 950 |

| Touchscrren height(mm) | 1500 | Air source (MPa) | 0.6 ~ 0.8 |

| Length of Packing Area(mm) | 2000 | Container Size(mm) | 121*191*120 |

| Transmission method | Servo motor drive | ||

W choose us?

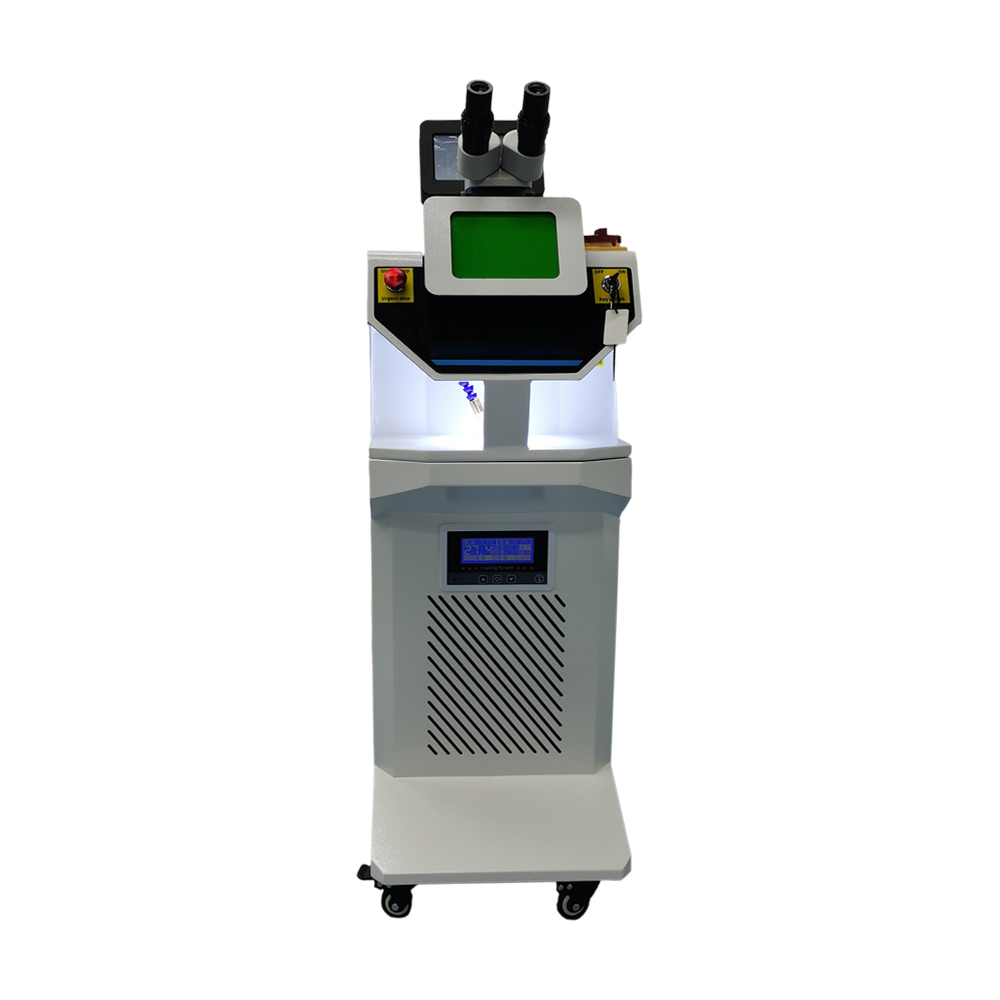

Ethercat Bus Technology

• Adopt the latest EtherCAT bus technology to realize intelligent production.

• Has good scalability.

• Remote maintenance possible. Drive System: • Using servo drive, the positioning accuracy can reach 0.1mm. • Servo system precisely drives the chain for precise positioning.

• Smooth movement, no noise, efficient, stable and reliable operation.

Data protection:

• Adopt UPS power-off protection control system.

• Intelligent error diagnosis and operation guidance prompts.

• The electrical cabinet is equipped with constant temperature and dehumidification, and the grid monitoring is digitized.

Sealing System:

• Active film feeding structure + swing arm tensioning structure + film position adjustment structure + film braking structure + cursor detection system + patented cantilever.

• Using German JSCC motor, the film feeding is precise and wrinkle-free.

• Easy and quick film replacement.