Rubber Bellows Expansion Joints DN32-DN3200 EPDM

Material Description

EPDM-Good heat resistance and suitable for alkaline waste water,compressed air terpolymer(oil free) and chemicals,weather- resistance,good gas tightness except for hydrocarbon.

NBR-Oil and fuel quality,also suitable for gases,solvents and fats.

Polytetrafluoroethylene (PTFE) has a series of excellent performance:

High temperature resistance: long-term use temperature 200 ~ 260 degrees;

Low temperature resistance: still soft at – 100 degrees;

Corrosion resistance: resistant to aqua regia and all organic solvents;

Weather resistance: the best aging life of plastics;

High lubrication: with the smallest friction coefficient in plastics (0.04);

Non-stickiness: It has the minimum surface tension in solid materials and does not adhere to any substance;

Non-toxic: physiological inertia.

Product advantage

1.The pump connector and expansion joint protects your pumps and reduces noise and vibration.

2.A durable joint for piping systems reaching temperatures up to 250°F (121°C), the joint differs from standard EPDM expansion joints by integrating cording and peroxide-cured EPDM. It is perfect for high-temp applications requiring modest pipe movement/expansion at higher temperatures.

3.The rugged, long-lasting material and construction will provide years of trouble-free operation at high temperature.An anchor wire, fully-wrapped with corded material, ensures a positive seal between the body and the floating flange.

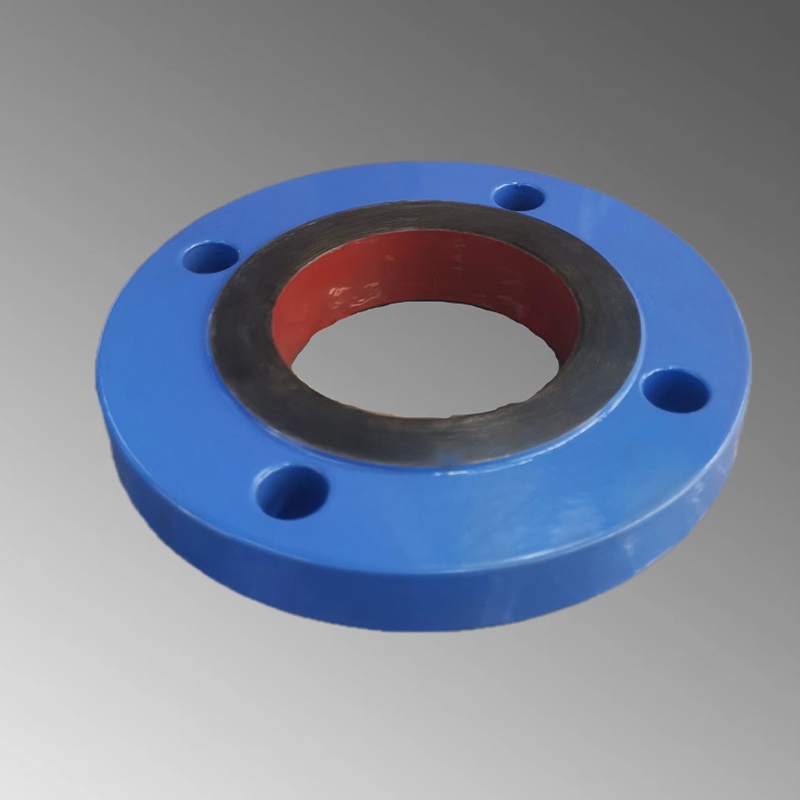

4.The Style rubber expansion joints are furnished complete with plated carbon steel flanges for corrosion protection. Q235 other 304 or 316 stainless steel flanges are available upon request as well as ANSI 150/250/300 lb., BS-10, DIN PN10 & PN16 and JIS-10K drilling.

5. reinforced, peroxide-cured EPDM rubber greatly enhances tolerance to high temperatures.Anchor wire wrapped with corded material ensures a positive seal between the body and the floating flange.Reduces noise and vibration.Isolates and protects the pump.Available in single and double sphere styles.

Rubber material of JGD flexible rubber joint

|

Rubber ball design |

Permissible operating data |

Electrical resistance |

Hardness shore A |

|||

|

Core (inner) |

Reinforcing material |

Cover (outer) |

bar |

℃ |

||

|

EPDM EPDM NBR NBR |

Nylon cord Aramid Nylon cord Aramid |

EPDM EPDM CR CR |

8 80 8 80 |

90 130 90 100 |

7×10^25×10^2 |

60 60 60 60 |

|

CSM NBR FKM |

Nylon cord Nylon cord

|

CSM CR EPDM |

8 10 10 |

90 80 150 |

4×10^2 5×10^2

|

65 55 65 |

Main connection size of JGD flexible rubber joint

|

Nominal Diameter (DN) |

Length (mm) |

Diameter of the central ring of the bolt(mm) |

Hole diameter -quality |

Axial Displacement |

Horizontal |

Deflection Angle(a1+a2)° |

||

|

mm |

inch |

Extension (mm) |

Compression (mm) |

|||||

|

40 |

1½ |

165 |

110 |

18-4 |

30 |

50 |

45 |

35 |

|

50 |

2 |

165 |

125 |

18-4 |

30 |

50 |

45 |

35 |

|

65 |

2½ |

175 |

145 |

18-4 |

30 |

50 |

45 |

35 |

|

80 |

3 |

175 |

160 |

18-8 |

35 |

50 |

45 |

35 |

|

100 |

4 |

225 |

180 |

18-8 |

35 |

50 |

40 |

35 |

|

125 |

5 |

225 |

210 |

18-8 |

35 |

50 |

40 |

35 |

|

150 |

6 |

225 |

240 |

22-8 |

35 |

50 |

40 |

35 |

|

200 |

8 |

325 |

295 |

22-8 |

35 |

50 |

40 |

35 |

|

250 |

10 |

325 |

350 |

22-12 |

35 |

60 |

35 |

30 |

|

300 |

12 |

325 |

400 |

22-12 |

35 |

60 |

35 |

30 |

|

350 |

14 |

330 |

460 |

22-16 |

35 |

60 |

35 |

30 |

|

400 |

16 |

330 |

515 |

22-16 |

35 |

60 |

35 |

30 |

|

450 |

18 |

330 |

565 |

26-20 |

35 |

60 |

35 |

30 |

|

500 |

20 |

350 |

620 |

26-20 |

35 |

60 |

35 |

30 |

|

600 |

24 |

350 |

725 |

30-20 |

35 |

60 |

35 |

30 |

|

700 |

28 |

350 |

840 |

30-24 |

35 |

60 |

35 |

30 |

|

800 |

32 |

400 |

950 |

30-34 |

35 |

60 |

35 |

30 |

Notes:

1. Rubber soft joint should not be installed beyond the limit of displacement.

2. Pipeline must have fixed support or bracket, and the force of fixed bracket must be greater than the axial force.

3. When installing vertically or overhead, fixing brackets and stress brackets should be installed at both ends of the product to prevent pulling-out after working under pressure.

Union rubber expansion joint

Union Material: Galvanized/Black Malleable Iron, SS304, SS316

Material: NBR, EPDM

Operating Pressure: PN16, 150LB

Size: DN15-80

Rubber Joint Case

Polytetrafluoroethylene (PTFE) uses industrial chemicals, petrochemical, oil refining, chlor-alkali, acid-making, phosphorus fertilizer, pharmaceuticals, pesticides, chemical fibers, dyeing, coking, gas, organic synthesis, non-ferrous smelting, steel, atomic energy and polymer filter materials, high purity product production (such as ionic membrane electrolysis), transportation and operation of viscous materials, hygiene. Highly demanding food and beverage processing and production departments.

In strict accordance with international standards and raw material quality requirements, has put an end to jerry-building and material reduction. Environmental protection standards, that is, raw materials of products need not only new materials, but also new materials of environmental protection level.

Rubber joint has good comprehensive performance, so it is widely used in chemical industry, construction, water supply, drainage, oil, light and heavy industry, refrigeration, health, water heating, fire protection, electric power and other basic projects, especially for pipelines with large vibration and frequent changes in heat and cold.

Rubber expansion joint Details

1.The raw material of flexible rubber expansion joint is high quality rubber,and the content of natural rubber is more than 50%.

2.The flange of JGD flexible single sphere rubber joint is made of high quality steel, large CNC machine,galvanized surface and standard flange typing.

3.All rubber expansion joints are finished with retaining flanges,and limit rod units are available on special request.

Material of the flanges: CS,CS zinc plating,CS hot dipped

galvanization.SS304,SS316,SS316L,SS321,SS310,SS904L,SS2205,SS2507

Sizes: range from DN32-DN3200

Design pressure: 10kg/cm2 16kg/cm2 20kg/cm2 25kgcm2