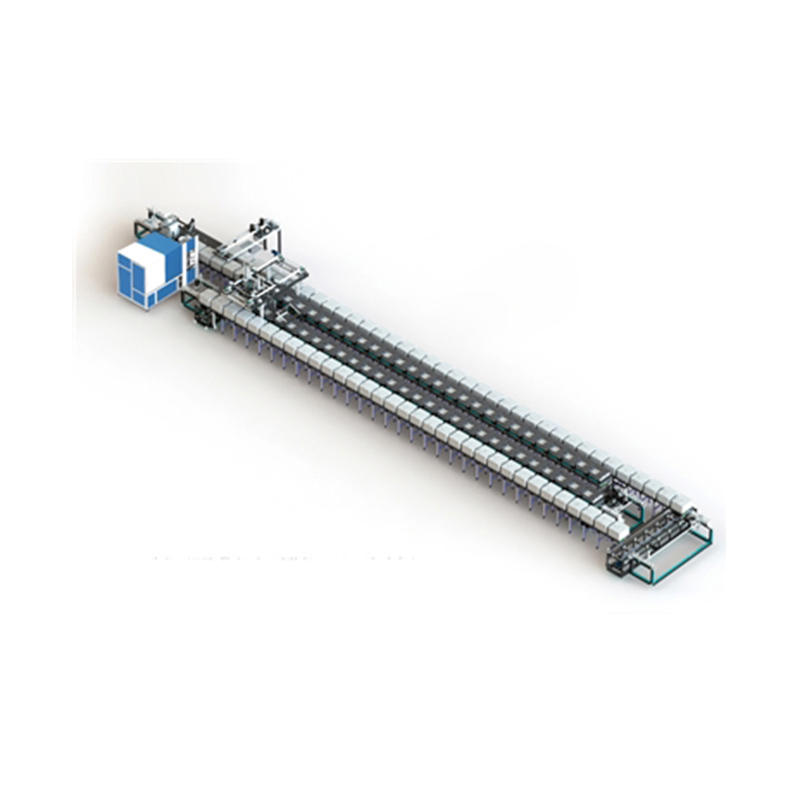

Servo Molding Machine Open Conveyor Line

Features

1. Smooth and reliable draulic drive operation

2. Low labor demand (two employees can operate on the assembly line)

3. Compact assembly line model transportation occupies less space than other systems

4. The parameter setting of pouring system and the flow inoculation can meet different pouring requirements

5.Pouring jacket and mould weight to ensure the quality of sand finished products

Mold and Pouring

1.Un-poured molds will be stored on the trolley of the conveyor line

2.The casting delay does not affect the operation of the molding machine

3.According to user needs to increase or decrease the length of the conveyor belt

4.Automatic trolley pushing facilitates continuous molding

5.Optional addition of pouring jacket and mould weight improves the quality of casting mold

6.Pouring can move forward with the mold and be poured at rest to ensure the pouring of all molds

Factory Image

Automatic Pouring Machine

Molding Line

Servo Top and Bottom Shooting Sand Molding Machine

Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.